Automatic and safe charging system of forage grass pusher

A charging system and automatic charging technology, which is applied to current collectors, electric vehicles, electrical components, etc., can solve the problems of manual charging and allow them to continue to work, and achieve the effects of simple structure, high reliability, and low voltage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

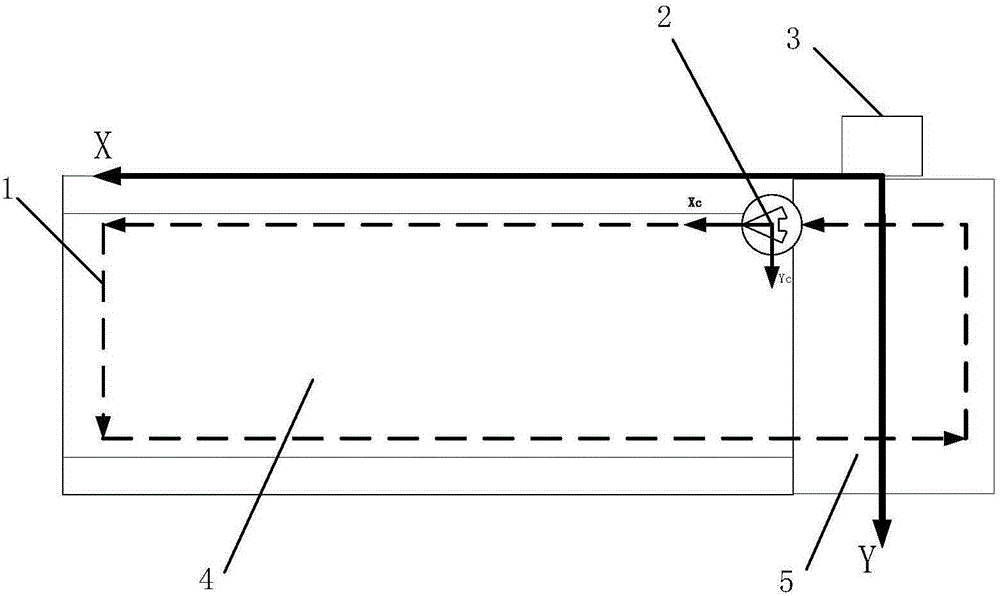

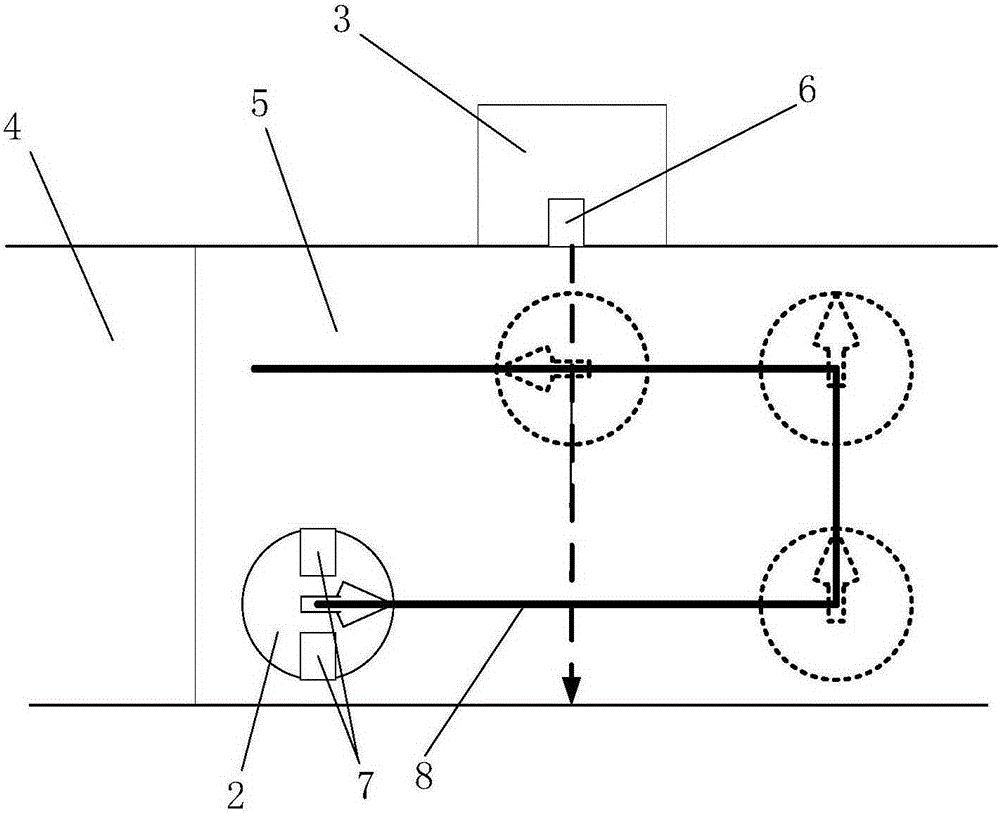

[0054] Such as Figure 1-8 As shown, the automatic safe charging system of the forage grass pusher of the present invention includes: an automatic charging station 3 matched with the forage grass pusher 2, the automatic charging station 3 is the origin of the position coordinates of the forage grass pusher 2, and the automatic charging Station 3 is installed on the set path 1 that forage pusher 2 walks;

[0055] The automatic charging station 3 and the forage pusher 2 are arranged in the same livestock farm, and the forage pusher 2 walks in the forage pushing working path area 4 and the charging path area 5. Obviously, the set path 1 should be located in the forage grass Push the working path area 4 and the charging path area 5.

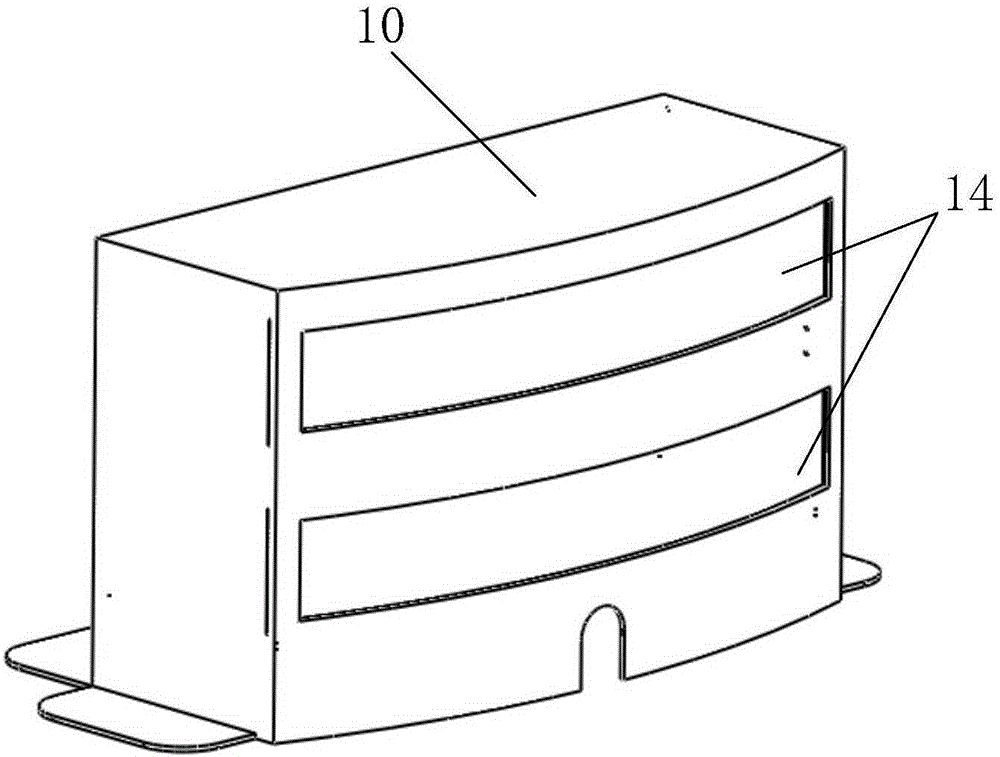

[0056] On the basis of the above technical solutions, such as Figure 4 As shown, the automatic charging station 3 includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com