Electric cylinder linear transmission structure

A technology of linear transmission and electric cylinder, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as complex design, and achieve the effects of simple maintenance, low cost, low noise, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

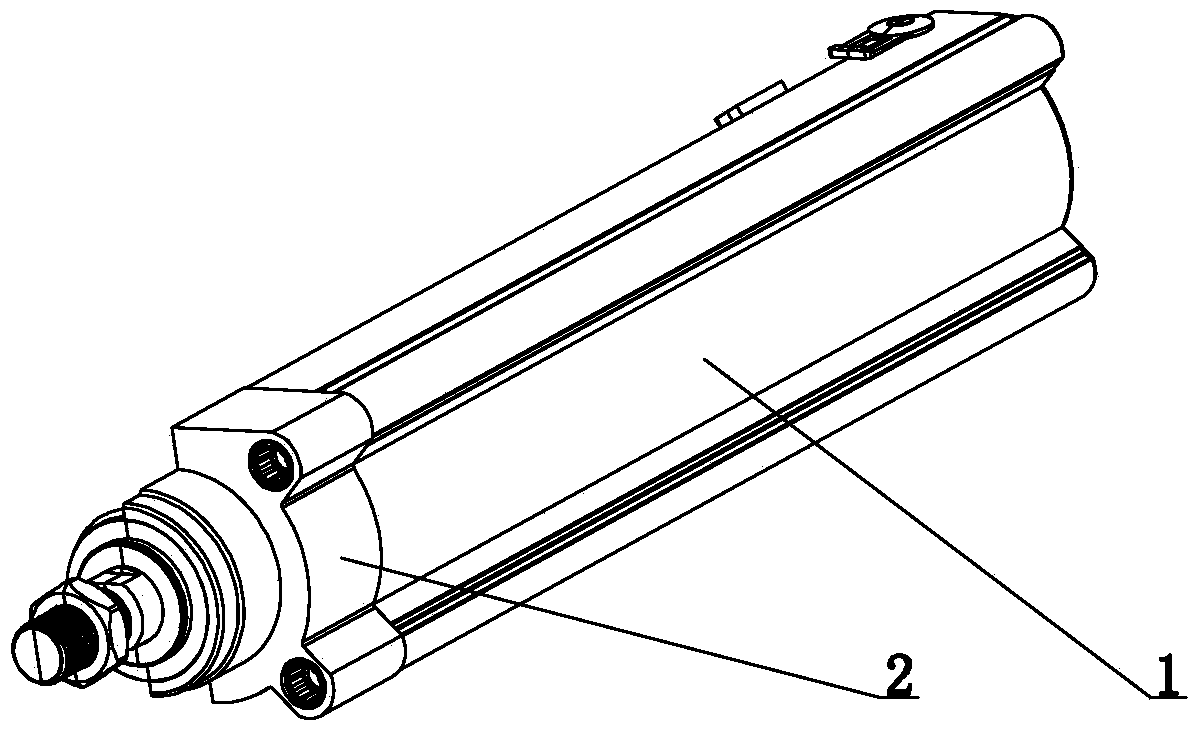

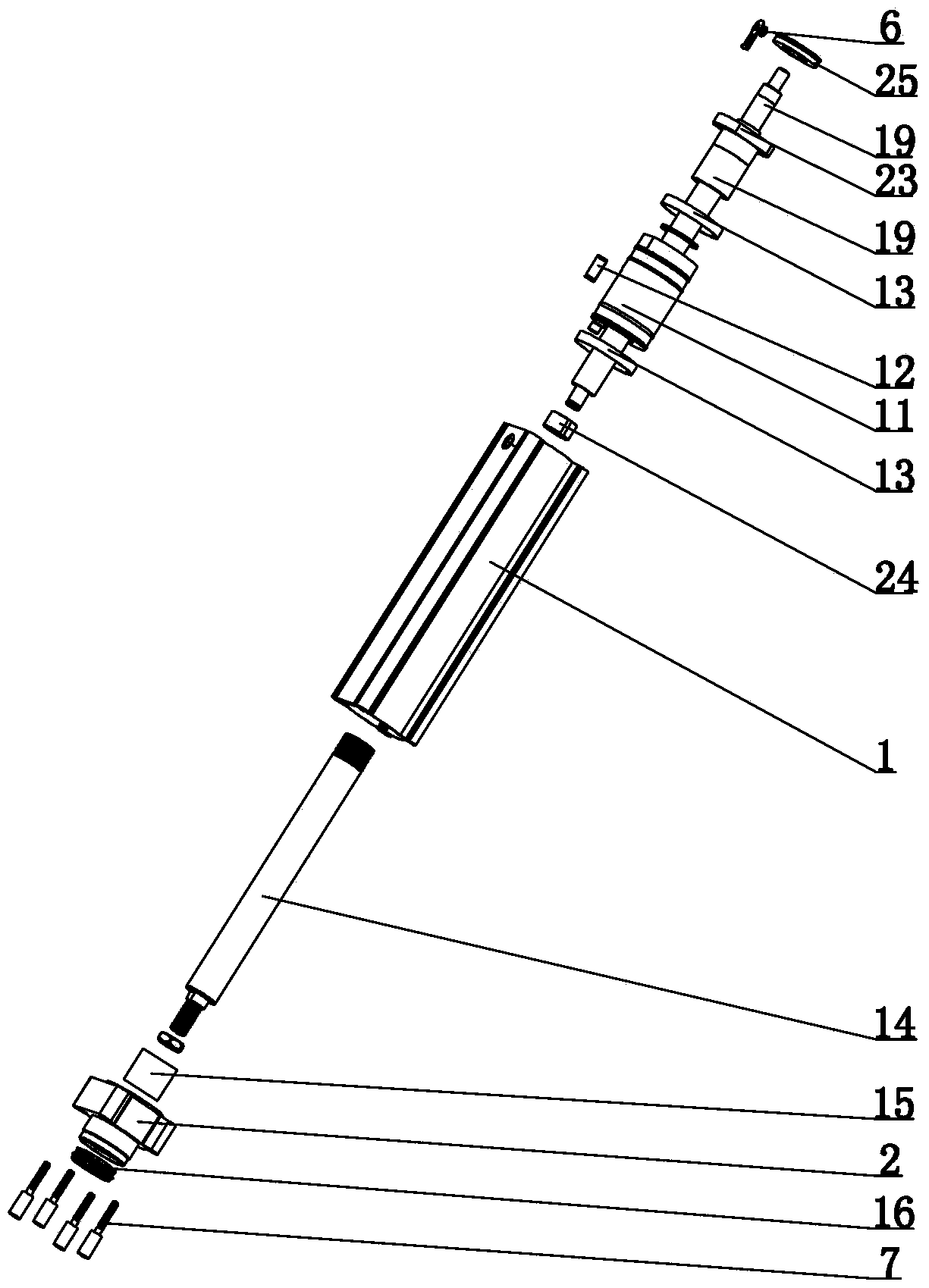

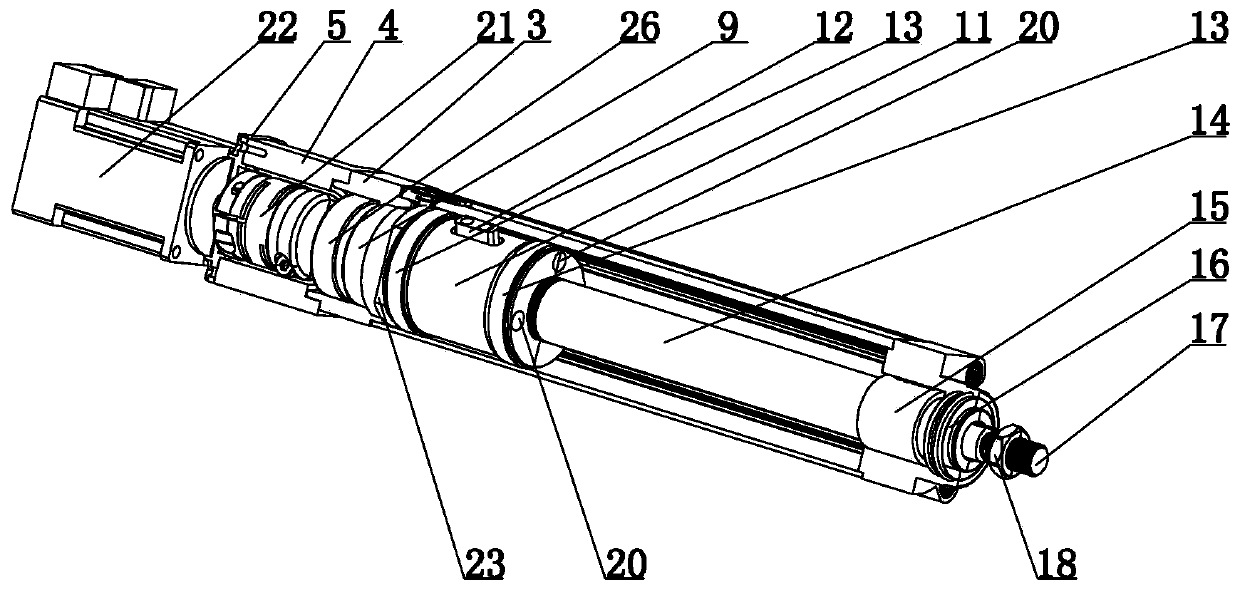

[0014] Such as figure 1 , 2 The electric cylinder linear transmission structure shown in 3 includes electric cylinder block 1, electric cylinder screw 19, screw nut fixing sleeve a11 and electric cylinder main rod 14. The electric cylinder screw 19 uses an imported ball screw, High efficiency and non-self-locking. The front end of the electric cylinder block 1 is provided with a front end fixing block 2, which is fixed between them by the electric cylinder screw 7. The electric cylinder screw 19 is covered with a screw nut fixing sleeve a11, the screw screw The central outer wall of the cap fixing sleeve a11 is provided with a screw nut fixing sleeve guide block 12, which is clamped on the longitudinal slot of the electric cylinder body 19, and the direction of the longitudinal slot is the same as that of the electric cylinder block. 1 The length direction is the same, the guide block 12 of the screw nut fixing sleeve slides back and forth in the electric cylinder block 1. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com