Piezoelectric system and layout method of power generation circuit

A technology of piezoelectric and piezoelectric units, which is applied in the field of road engineering and energy harvesting, can solve the problems of few reports on the layout of piezoelectric systems, and achieve the effects of enhancing output collection efficiency, optimizing embedding methods, and increasing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

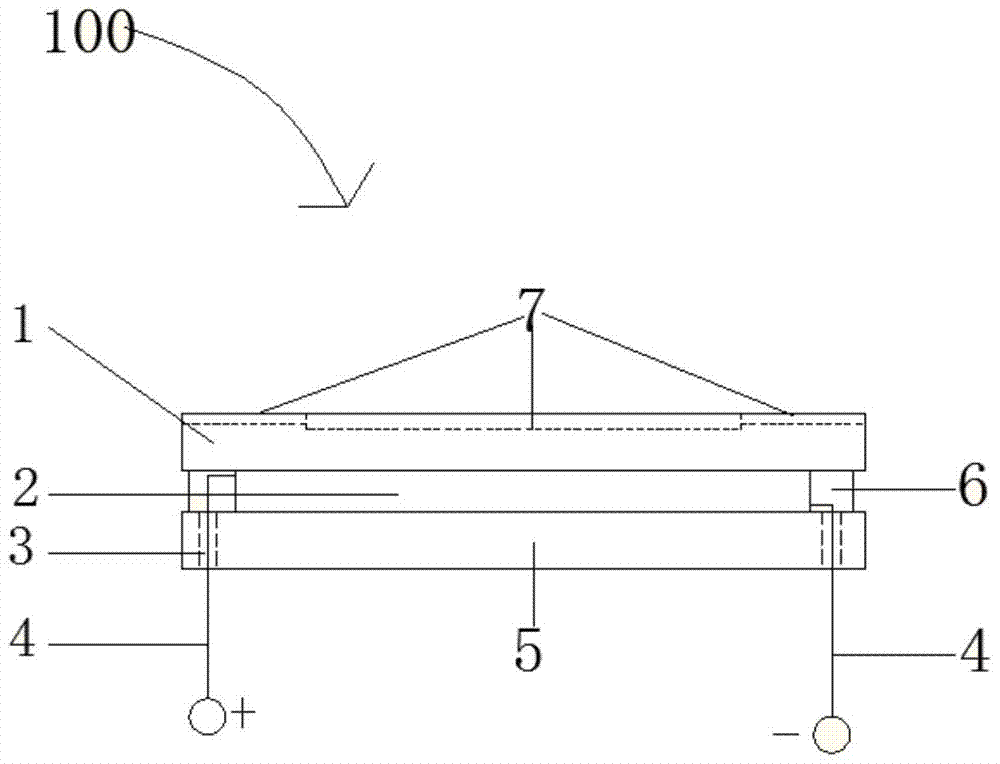

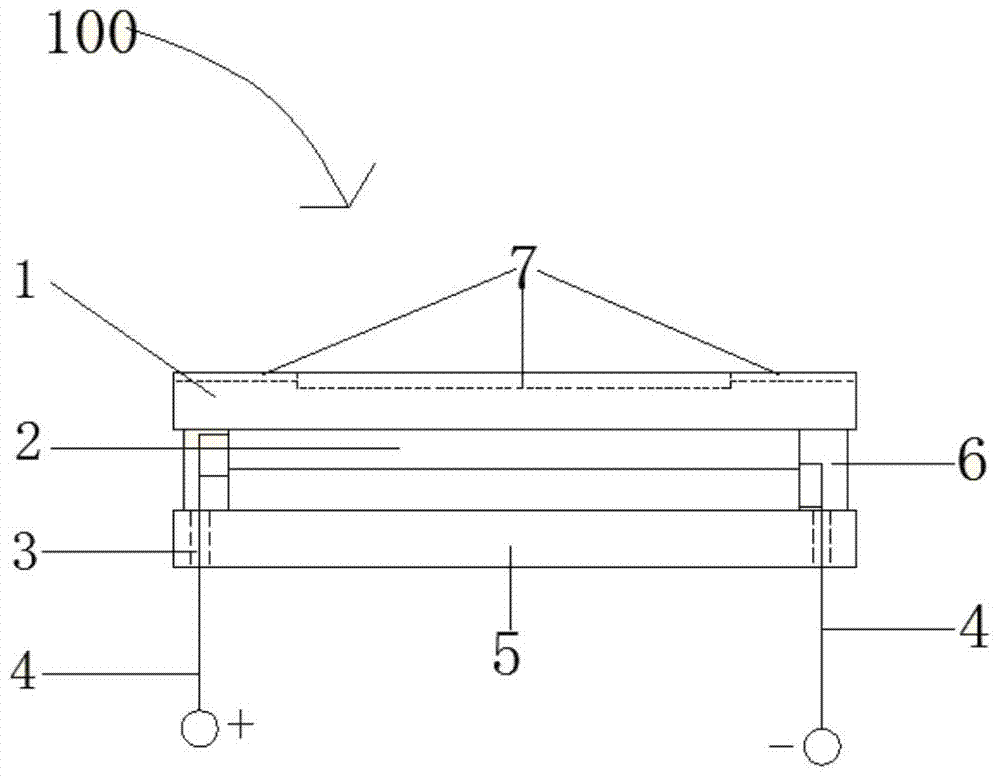

[0062] Step 1, assemble the piezoelectric unit

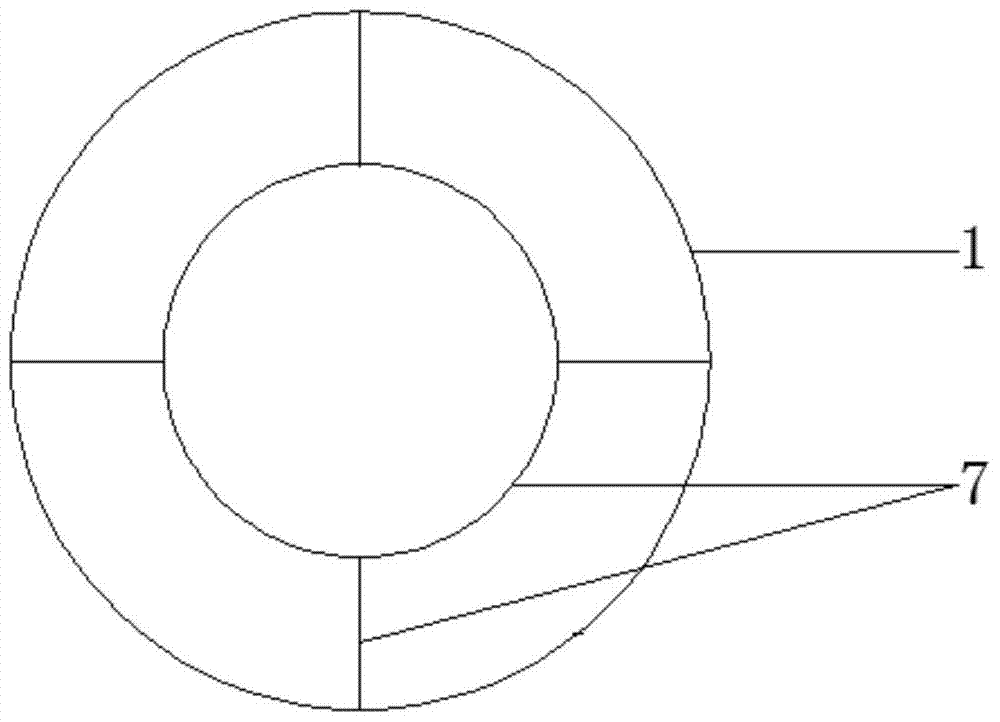

[0063] The copper plate is made of beryllium bronze circular plate, roughened on both sides to make the surface rough, and the stress absorption groove is processed by a precision lathe. The groove depth accounts for about 1 / 4 of the thickness of the copper plate, such as figure 1 As shown; the rubber pad is an ordinary circular silicon rubber pad, which is equal in size to the copper plate. It is roughened on both sides to make the surface rough, and a hole is drilled at each end of the diameter near the edge. The specific hole size is based on the total width of the wire. ; The piezoelectric element adopts a single piece of PZT piezoelectric ceramics, the diameter is slightly smaller than the copper plate and the rubber pad. Use acetone or dimethylformamide to clean the copper plate, piezoelectric element, and rubber pad and then dry them. Use epoxy resin to bond each element and package it into a piezoelectric unit, as shown ...

Embodiment 2

[0070] The steps of this embodiment are basically the same as those of Embodiment 1, except that as shown in Figure 5(b), four piezoelectric unit strips are arranged in the width direction of the road, and the corresponding piezoelectric unit in the adjacent piezoelectric unit strips The connection line between them is perpendicular to the central axis of the lane, the horizontal spacing L2 of the piezoelectric unit belt is 10cm, the longitudinal spacing of adjacent piezoelectric units in each piezoelectric unit belt is 2.5m, and the distance between the piezoelectric unit belt and the central axis of the lane is L3. L1 is 40cm.

Embodiment 3

[0072] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that: as shown in Figure 5(c), three piezoelectric unit belts are arranged in the width direction of the road, and piezoelectric unit groups are arranged on each side of the central axis of the lane. Two rows, two rows are set up next to each other; the connection between the corresponding piezoelectric units in each row of adjacent piezoelectric unit belts is perpendicular to the central axis of the lane, the transverse distance L2 of the piezoelectric unit belts is 15cm, and each piezoelectric unit belt The longitudinal distance between adjacent piezoelectric units is L3 is 2.5m, and the distance L1 between the piezoelectric unit belt and the central axis of the lane is 40cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com