Uniform barometric pressure micro-plasma discharge device with flow equalizing system

A micro-plasma and discharge device technology, applied in the direction of plasma and electrical components, can solve the problems of complicated maintenance and high cost, and achieve the effects of good current equalization effect, reasonable structure and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

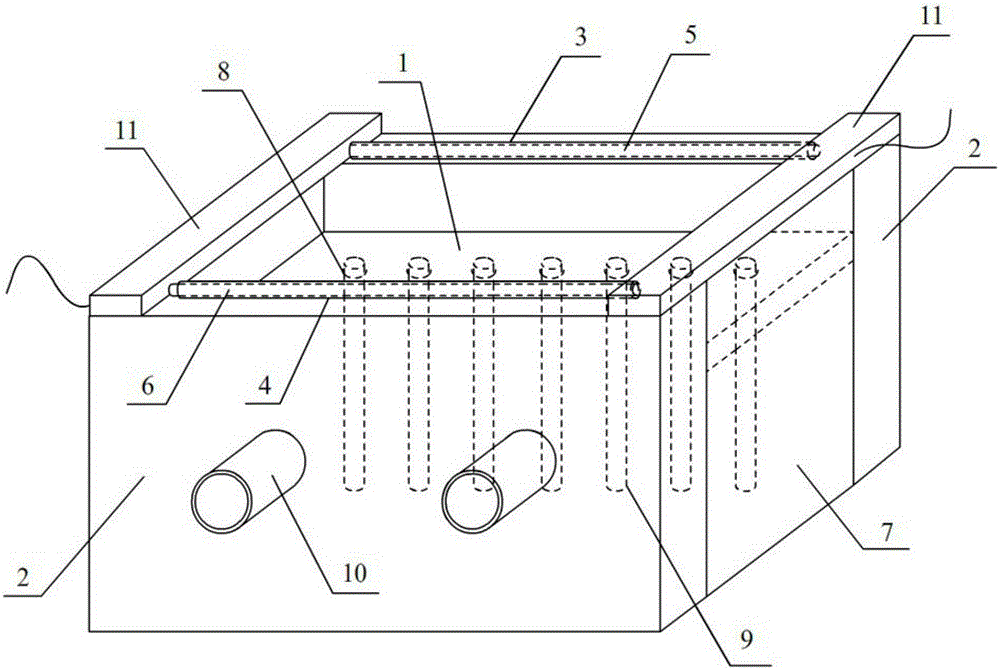

[0030] like figure 1 As shown, the dielectric plate A is in the shape of a cuboid, which contains a cylindrical jack, and the dielectric tube C is inserted into it, which can evenly flow the discharge gas entering from the air inlet. The dielectric plate B is a solid cuboid, and the dielectric plate A is clamped and Use AB glue to connect with the dielectric board A, and use insulating sealing plates to seal the openings on both sides of the two dielectric boards B, so that the whole forms an H-shaped box structure.

[0031] Dielectric tube A opens on the left side and inserts an electrode made of tungsten wire, and the right side opening of dielectric tube B inserts an electrode made of tungsten wire. The electrode in dielectric tube A is used as a high-voltage electrode, and the electrode in dielectric tube B is used as a ground electrode. The dielectric board C is fixed on both ends of the top of the dielectric board B, and plays the role of fixing and insulating. Among th...

Embodiment 2

[0033] The dielectric plate A is in the shape of a cuboid, which contains a cylindrical jack, and the dielectric tube C is inserted into it, which can evenly flow the discharge gas entering from the air inlet. The dielectric plate B is a solid rectangular parallelepiped. The dielectric plate A is clamped and fixed using The method is connected with the dielectric board A, and the openings on both sides of the two dielectric boards B are sealed with insulating sealing plates to form an H-shaped box structure as a whole.

[0034] The left side opening of the dielectric tube A is inserted with an electrode made of copper wire, and the right side of the dielectric tube B is inserted with an electrode made of copper wire. The electrode in the dielectric tube A is used as a high-voltage electrode, and the electrode in the dielectric tube B is used as a ground electrode. The dielectric board C is fixed on both ends of the top of the dielectric board B, and plays the role of fixing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com