Tea roasting machine

A frying machine and tea technology, which is applied in tea treatment before extraction, etc., can solve the problems of tea chlorophyll damage, uneven heating of tea, high tea breakage rate, etc., achieve emerald green color, good stir-frying effect, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

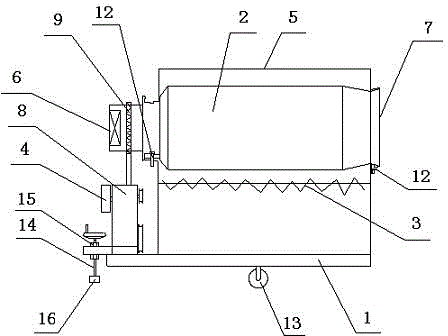

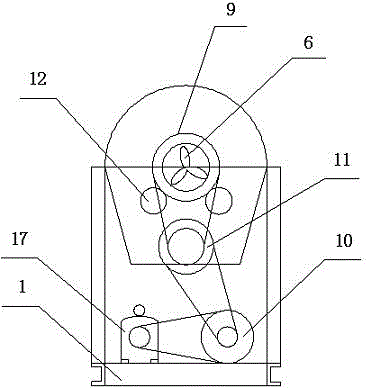

[0010] As an embodiment of the present invention, such as figure 1 and figure 2 As shown, a tea frying and drying machine includes a frame 1, the upper part of the frame 1 is rotatably connected with a drum 2, and the frame 1 is provided with a transmission variable speed regulating mechanism for driving the drum 2 to rotate, and the drum 2 is A hollow cylinder arranged horizontally, an electric furnace shell 5 is arranged outside the drum 2, an electric furnace 3 is arranged inside the electric furnace shell 5, the electric furnace 3 is arranged under the drum 2, and a fan 6 is installed at one end of the drum 2, and the The blower fan 6 has both blowing and exhausting functions, controlled by the reverse switch, which can dissipate heat in time or extract the water vapor in the drum 2 according to the needs, so as to improve the stir-frying efficiency and achieve a better stir-frying effect. The other end of the drum 2 is provided with a material inlet and outlet 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com