Hydraulic rice washer for ship

A rice washing machine and water pressure technology, which is applied in the field of marine water pressure rice washing machines, can solve the problems of not having height adjustment, not being able to work well in the field of ships, and not being able to effectively prevent corrosion of ships from humidity and sea wind.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

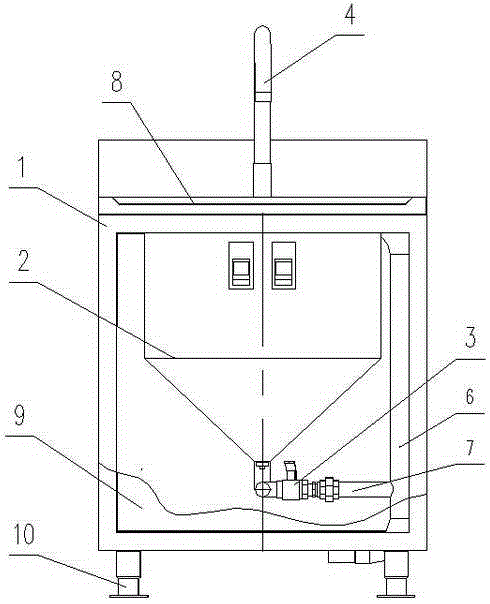

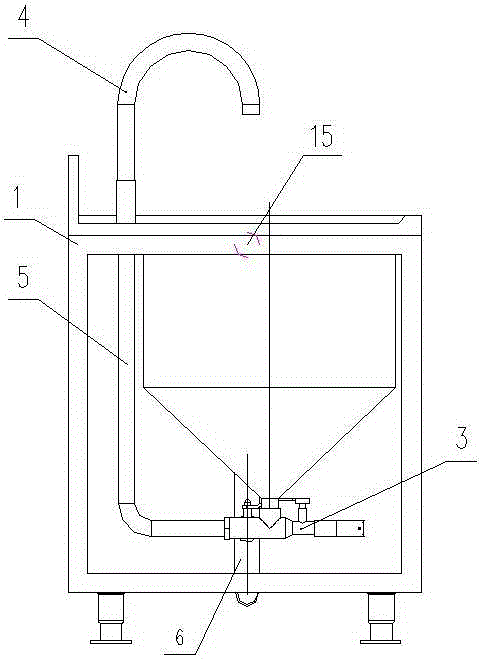

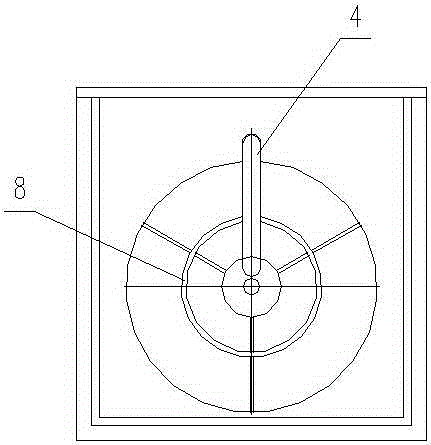

[0015] A marine hydraulic rice washing machine of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The accompanying drawings constituting this application are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

[0016] Depend on figure 1 , figure 2 , image 3 , Figure 4 It can be seen that a marine hydraulic rice washing machine in this embodiment includes a shell 1 made of high-quality stainless steel sheet metal forming process, a rice washing bucket 2 and a throttling four-way valve 3 . The rice washing bucket 2 is arranged in the housing 1, and the throttling four-way valve 3 is installed on the lower end of the rice washing bucket 2, and the outlet of the lower end of the rice washing buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com