A wet electrostatic precipitator and its spraying system

A wet electrostatic precipitator and spray system technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of making full use of unfavorable spray water, reducing spray pressure, and complicated piping layout, avoiding the The effect of short-term discharge exceeding the standard, reducing water consumption, and avoiding dead ends of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

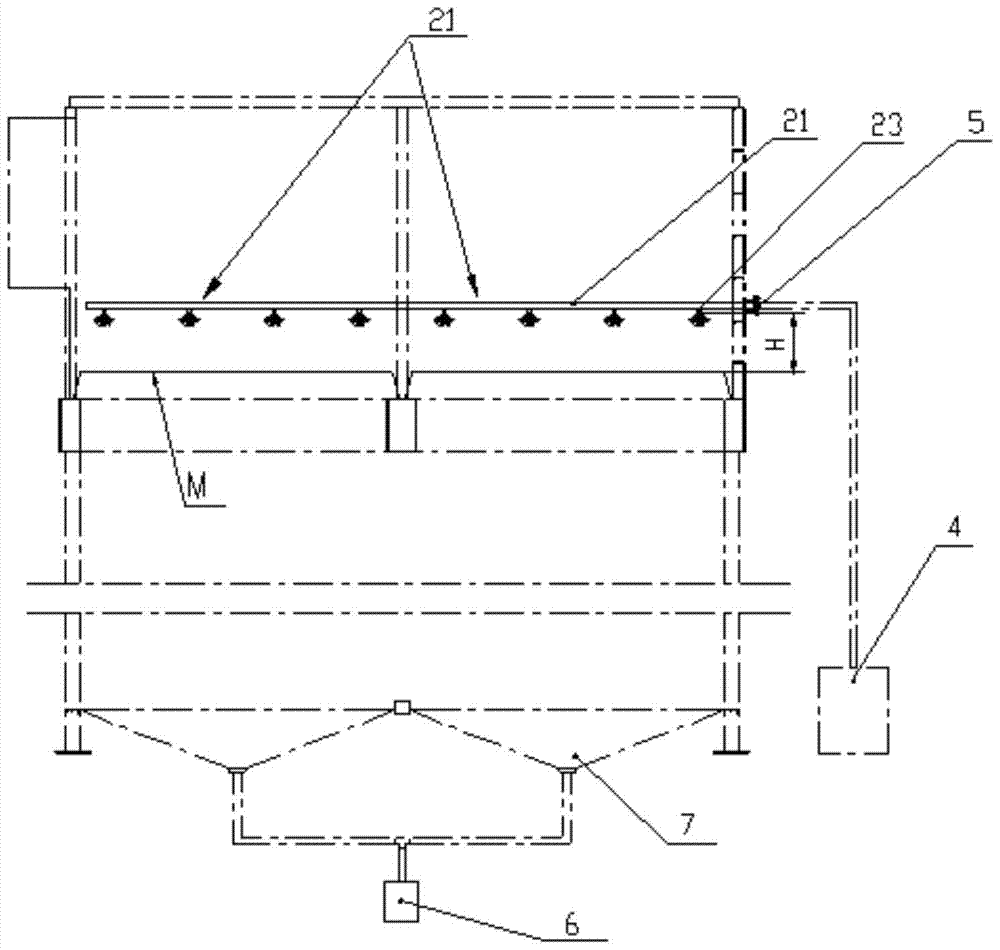

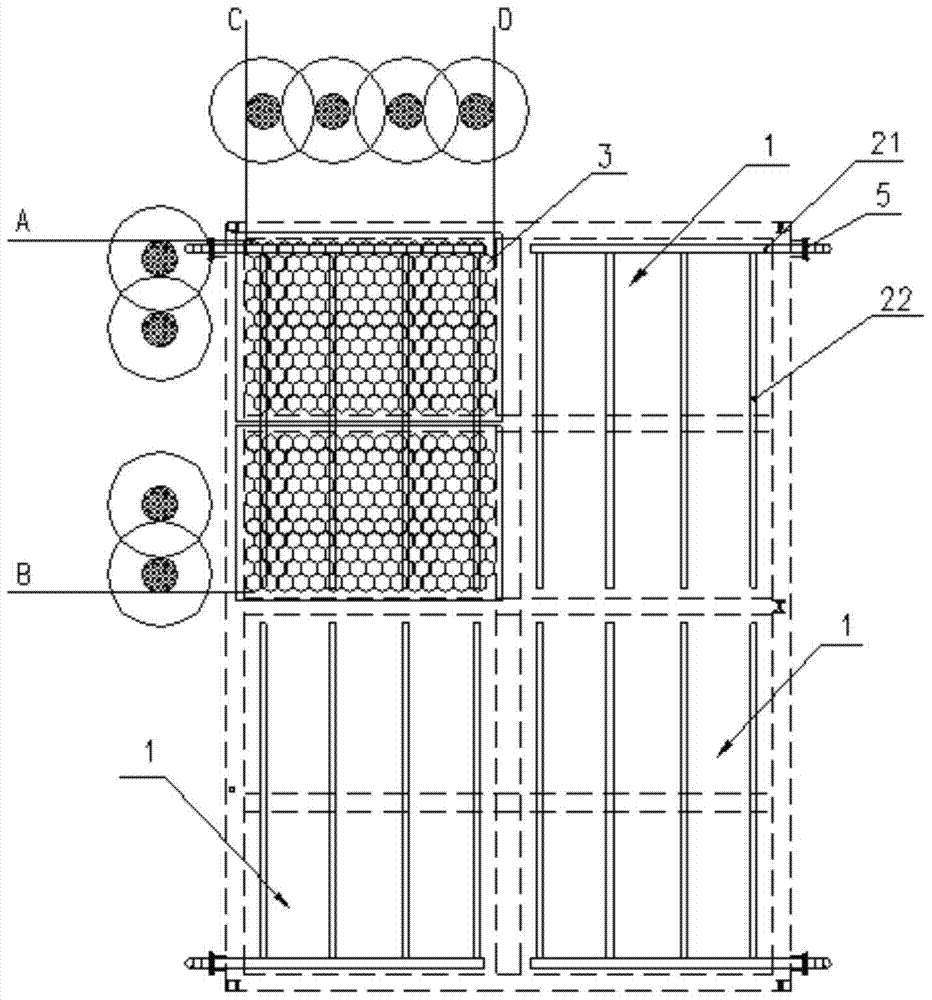

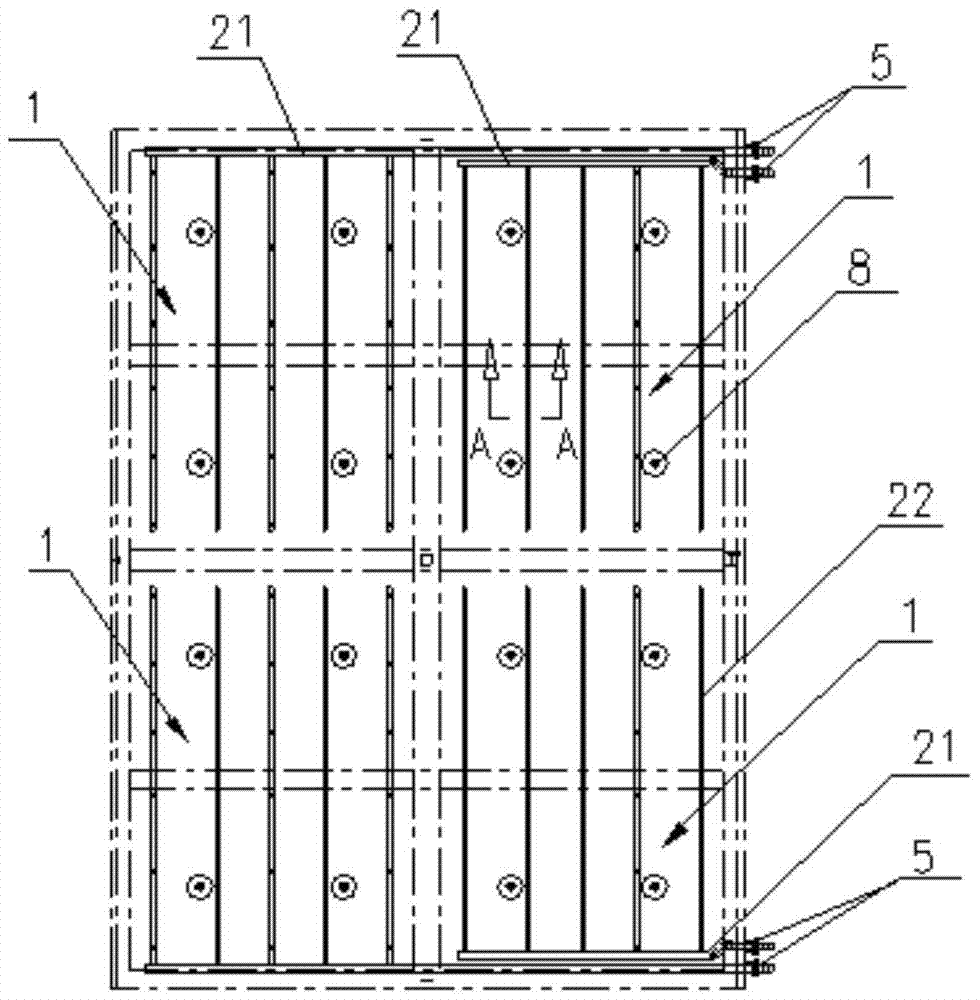

[0028] The core of the present invention is to provide a spraying system of a wet electrostatic precipitator, which can realize a reasonable arrangement of spraying pipelines, ensure efficient dust removal, and ensure a safe discharge distance.

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0030] The up and down in the present invention are defined with reference to the use state of the wet electrostatic precipitator: when the wet electrostatic precipitator is placed normally, the vertical direction is the direction perpendicular to the ground, and in the vertical direction, the direction close to the ground is the downward direction, away from The direction of the ground is upward; a plane parallel to the ground is defined as a horizontal plane; in the horizontal plane, the direction in which each spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com