High-accuracy high-speed micro-cutting three-dimensional dynamic force testing platform

A three-dimensional dynamic and test platform technology, applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of complex and bulky structures, bulky volume, etc., and achieve high sensitivity, strong working reliability, and wide processing range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

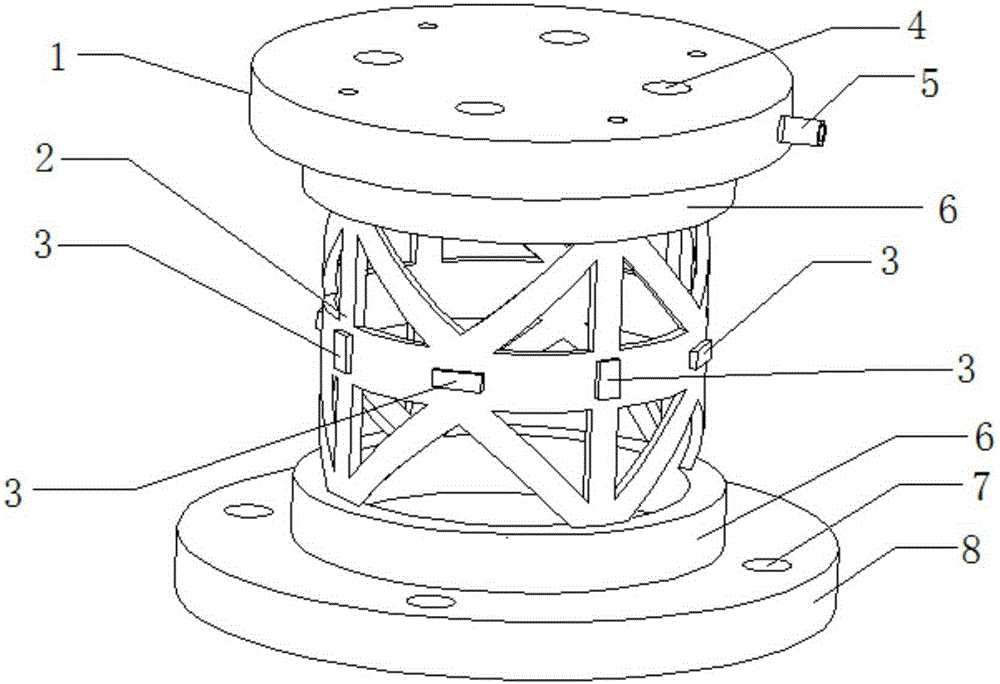

[0017] Such as figure 1 As shown, a high-precision high-speed micro-cutting three-dimensional dynamic force testing platform of the present invention includes a support positioning base 8, an electromagnetic force processing platform 1, a pair of high-rigidity elastic thick-walled elements 6 and high-rigidity thin-walled hollow elastic elements 2. A pair of high-rigidity elastic thick-walled elements 6 are installed on the supporting positioning base 8, and a high-rigidity thin-walled hollow elastic element 2 is installed between the pair of high-rigidity elastic thick-walled elements 6, and the high-rigidity elastic thick-walled element 6 An electromagnetic force processing platform 1 is installed on the top of the electromagnetic force processing platform 1, and a cable interface 5 is installed on one side of the electromagnetic force processing platform 1, and a circumferentially evenly distributed strain gauge 3 is arranged in the middle of the high-rigidity thin-walled hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com