Rotary motor casing processing fixture

A tooling fixture and rotary technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unguaranteed position of holes, difficulty in meeting drawing requirements, low product qualification rate, etc., to achieve Reduced processing time, shortened clamping time, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

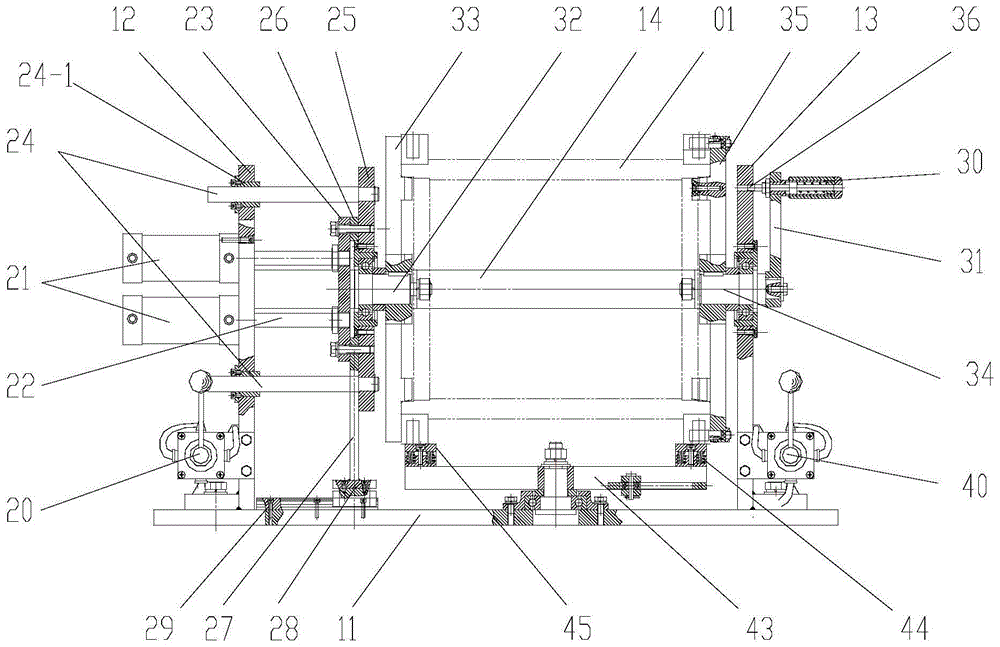

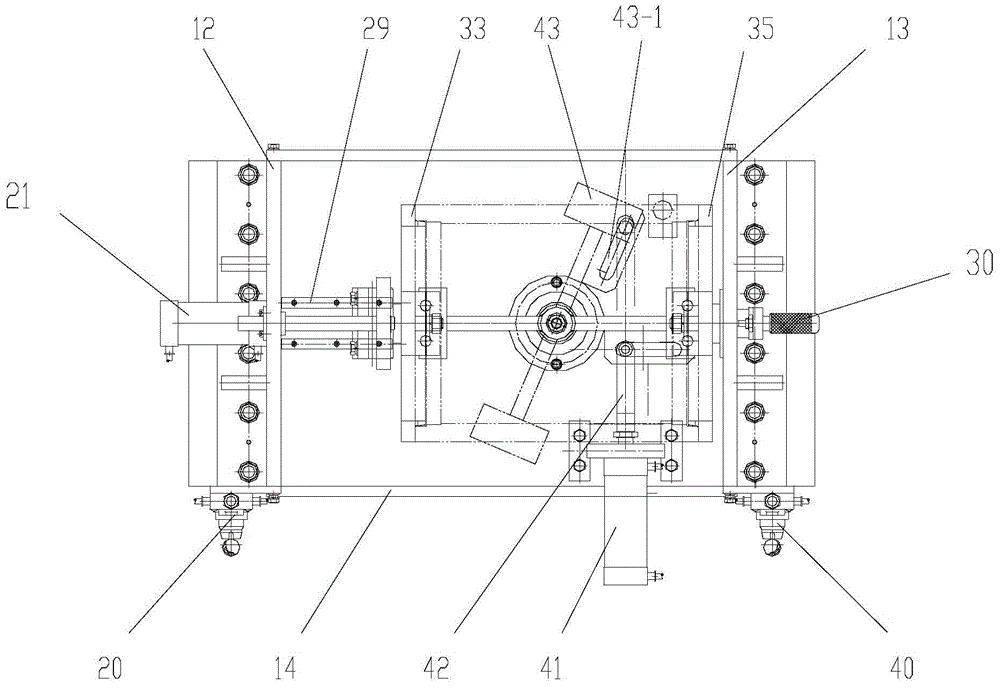

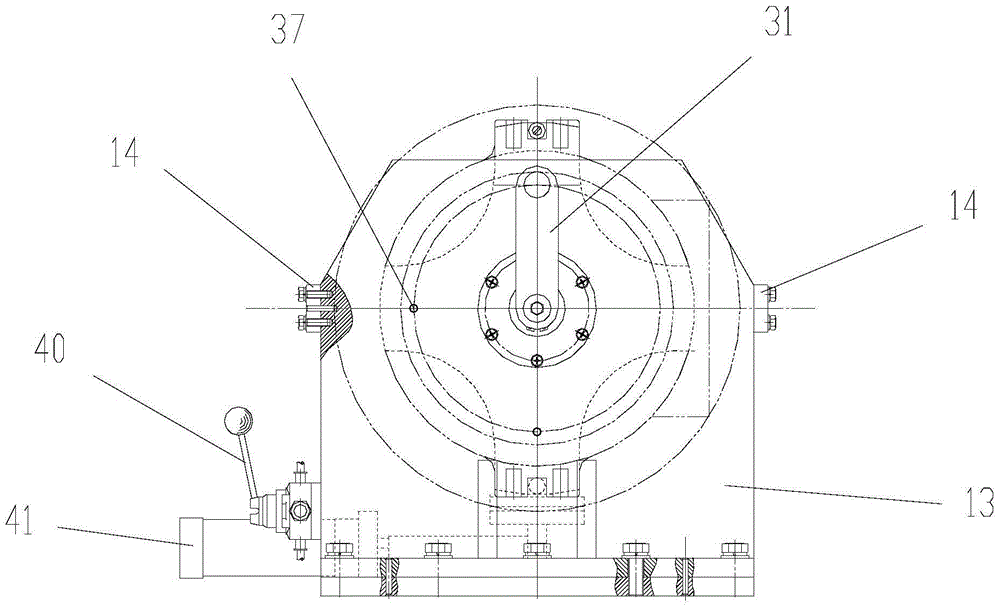

[0021] See the accompanying drawings for details. This embodiment provides a rotary motor casing processing fixture, including a tooling frame mechanism, an axial clamping mechanism, a rotating mechanism, and a bottom support mechanism. The axial clamping mechanism, the bottom support mechanism They are respectively connected with the tooling frame mechanism, and the rotating mechanism is connected with the axial clamping mechanism. The tooling frame mechanism includes a bottom plate 11, a left brace 12, a right brace 13 and a drawstring 14. The left brace and the right brace The plate is fixed by a drawstring, and the left support plate, the right support plate and the bottom plate are vertically fixed to form an overall tooling frame.

[0022] The axial clamping system performs axial fastening on the casing workpiece, including clamping pneumatic switch 20, cylinder 21, cylinder drive rod 22, drive plate 23, guide rod 24, force plate 25, backing plate 26, sliding support Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com