Three-dimensional printing machine fluid extrusion system and implement method thereof

A 3D printer and fluid technology, used in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of difficult to compact materials, difficult to accurately measure, slow printing speed, etc., to achieve uniform and compact object molding, extended application Scope, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

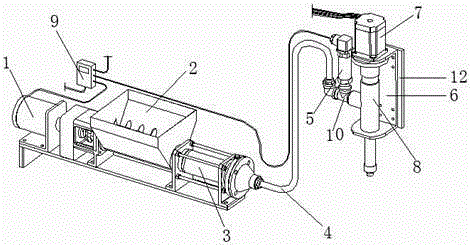

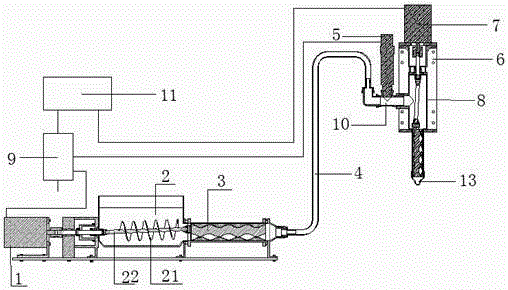

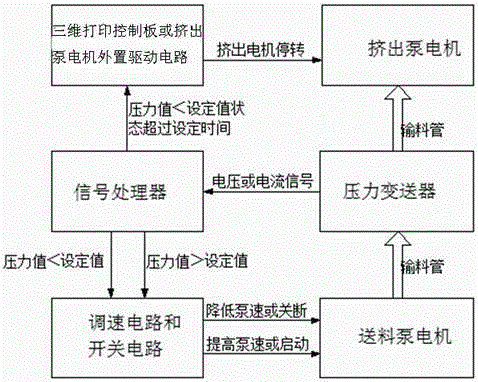

[0041] Such as Figure 1-Figure 7 As shown, this embodiment provides a fluid extrusion system for a 3D printer. The extrusion system is mainly composed of three parts: an extrusion mechanism, a feeding mechanism, and a feeding control system. The above three parts cooperate to complete the feeding and extruding operation in the process of three-dimensional printing. At the same time, the feeding control system adjusts the feeding and extruding state according to the pressure feedback signal of material conveying.

[0042]The feeding mechanism includes a mounting bracket, a feeding pump motor and its supporting transmission mechanism, a hopper and a feeding screw mechanism. In this embodiment, the structure of the feeding screw mechanism has two optional modes:

[0043] First, the feeding screw mechanism is composed of the screw pump rotor, stator, stator outer wall, connecting shaft, transmission shaft, universal joint, shaft seal and other supporting accessories; the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com