Lightweight knitted fabric

A knitted fabric, light and thin technology, applied in the direction of knitting, weft knitting, textile and paper making, etc., can solve the soft feeling of texture, wearing comfort, moisture absorption and breathability, elasticity and stretch limit, reduce fabric weight, reduce fabric shape retention and other issues, to achieve the effect of satisfying individual pursuits, improving rupture strength, and solving monotonicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

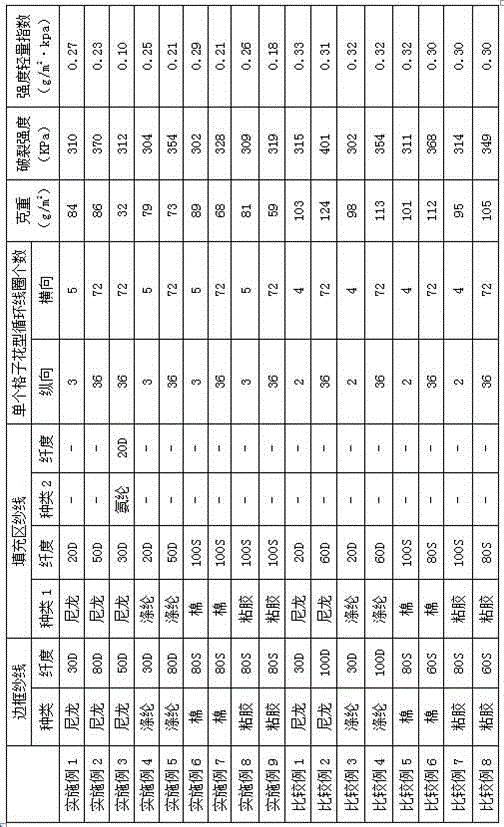

[0023] Use 30D nylon yarn as the yarn for the lattice frame, and 20D nylon yarn as the yarn for the filling area, and weave it into a lattice weave on a single-jersey circular knitting machine. Among them, the number of longitudinal coils of the lattice is 3, the number of transverse coils is 5, and the grammage of the prepared sample is 85g / m 2 , the burst strength is 312KPa, and the strength and light weight index is 0.27g / m 2 kpa, the performance parameters of the obtained fabric are shown in Table 1.

Embodiment 2

[0025] Use 80D nylon yarn as the yarn for the lattice frame, and 50D nylon yarn as the yarn for the filling area, and weave it into a lattice weave on a single-jersey circular knitting machine. Among them, the number of longitudinal coils of the grid is 36, the number of transverse coils is 72, and the grammage of the prepared sample is 90g / m 2 , the burst strength is 370KPa, and the strength and light weight index is 0.24g / m 2 kpa, the performance parameters of the obtained fabric are shown in Table 1.

Embodiment 3

[0027] Use 50D nylon yarn as the lattice frame yarn, 30D nylon yarn and 20D spandex as the filling area yarn, and weave it into a lattice weave on a single-sided circular knitting machine. Among them, the number of longitudinal coils of the lattice is 36, the number of transverse coils is 72, and the grammage of the prepared sample is 32g / m 2 , the burst strength is 312KPa, and the strength and light weight index is 0.11g / m 2 kpa, the performance parameters of the obtained fabric are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com