rotary internal combustion engine

An internal combustion engine, rotary technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of pistons that cannot be cooled and effectively lubricated, difficult to burn, difficult to cool, etc., to solve the problems of unable to cool and effectively lubricate, improve Ignition and combustion performance, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

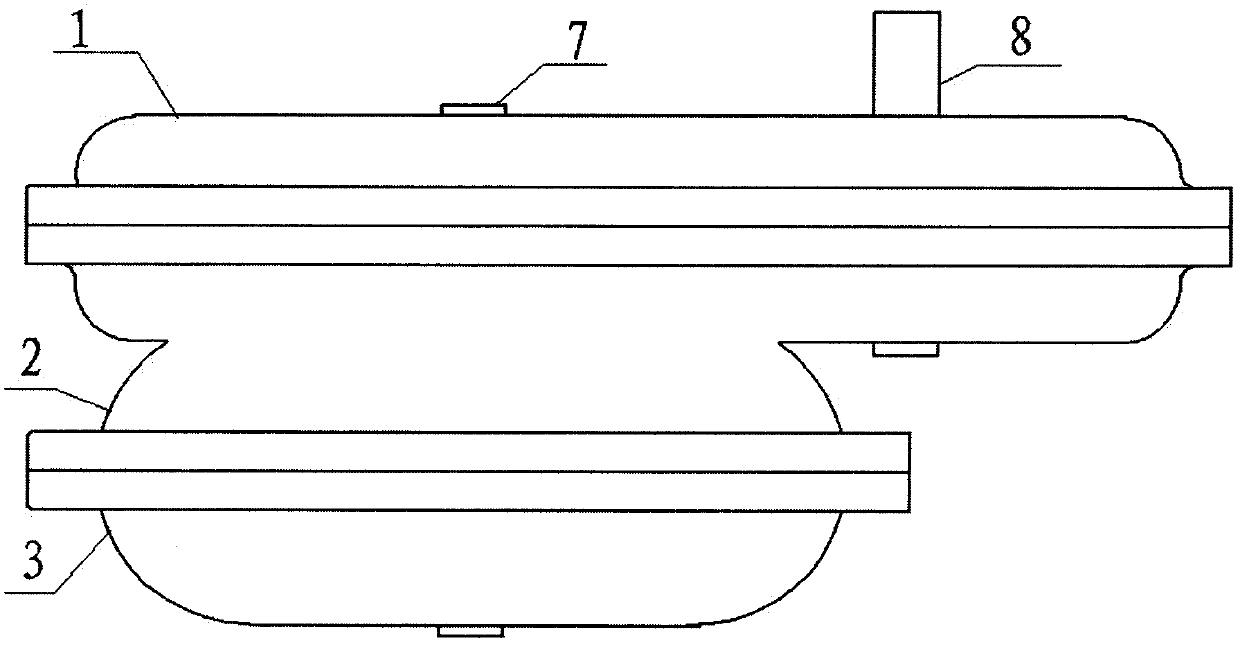

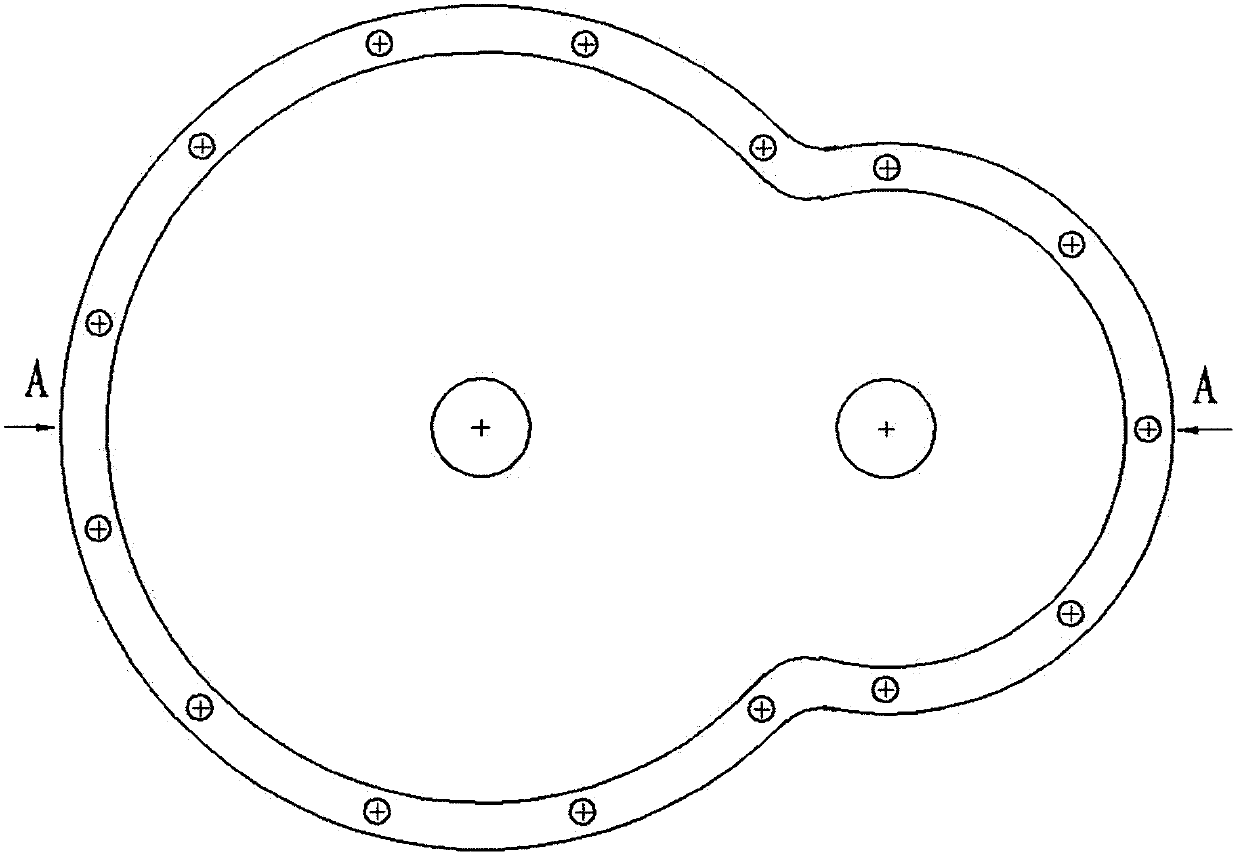

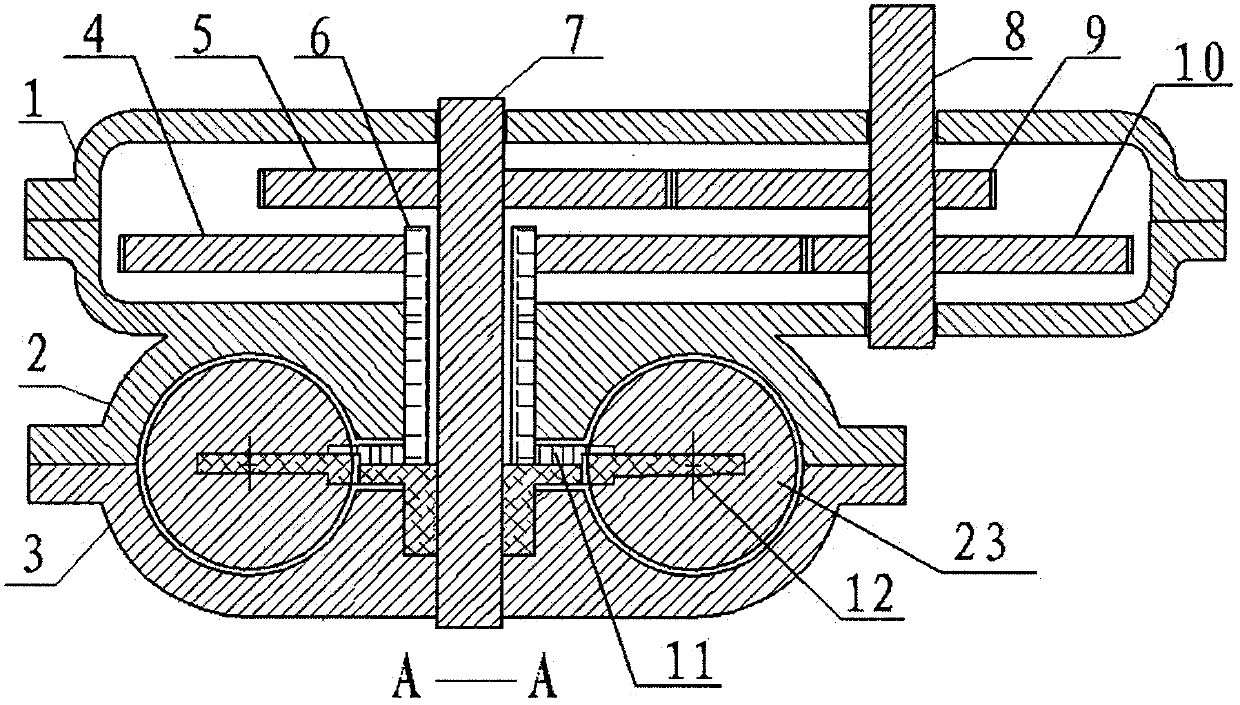

[0050] Implementation method 1: This structure includes a set of annular cylinders with circular cross-sections composed of two annular cylinders 2 and 3 with semicircular cross-sections, and the gear box is arranged on one side of the cylinders, such as figure 1 , 2 , 3, 4, 5, and 6; the cylinder body is provided with an oil passage 31 specially for the circulation of lubricating oil near the end of the air inlet 38, and the oil passage is sealed with a porous material 32, which can make the lubricating oil seep out. Ensure that the piston ring is effectively lubricated when the piston passes, such as Figure 7 , 8 As shown, the arrow in the figure is the flow diagram of lubricating oil; the intake hole 38 and the exhaust hole 39 on the cylinder block are all strip-shaped, and the strip shape of the intake and exhaust holes is arranged according to the forward direction of the piston rotation One end of the intake and exhaust holes in the forward direction of the piston is ...

Embodiment approach 2

[0051] Implementation method 2: two identical, independent gearboxes 42 and 43 that are completely separated from the cylinder except where there are shaft holes are provided; two identical annular cylinders with a semicircular section are provided 35, 40, forming a set of circular cylinder with circular section; two rotor shafts 13, 16 are installed on the two rotors respectively, and two non-circular gears 4, 5 are respectively installed in two independent gear boxes, Mesh respectively with two eccentric gears 9,10 installed on the same power output shaft 41, as Figure 35 , 36 , 37; Such setting is more conducive to the cooling of the cylinder block and the setting of the intake and exhaust holes, and the assembly of other supporting facilities; except that the above feature setting, other are all the same as the implementation method one.

[0052] The working principle of this structure is as follows: it uses the difference in rotation angle between the two eccentric gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com