Bracing wire suppression vibration device

A technology for suppressing vibration and tension device, applied in the field of wind tunnel test, it can solve the problems of increasing the risk of the test, affecting the accuracy of aerodynamic data, difficult to accurately obtain the maximum lift coefficient, stall angle of attack, etc., so as to reduce the test risk and suppress the model Vibration, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

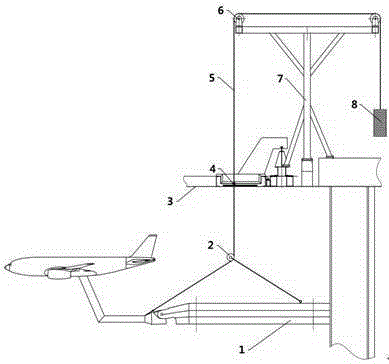

[0037] The present invention uses weights to pull steel cables to offset the reaction force on the aircraft model. The present invention sets a bracket on the outer wall of the top of the wind tunnel, and the upper end of the bracket is a horizontal horizontal frame. The pulley and the fixed pulley are respectively arranged on the two edges of the horizontal frame. A steel cable A is used. One end of the steel cable A is connected to the weight. The guide steel sleeve is then connected to the pole. In order to ensure the uniformity of the force on the steel cable A, it is necessary to set a movable pulley on the steel cable A. The movable pulley is set in the wind tunnel on the steel cable A, and a steel cable B is connected to the movable pulley. , and the other end of cable B is connected to the cantilever. In order to neutralize the force on the aircraft model more evenly, two steel cables A are set. The two steel cables A are connected to a point on the pole, and then the...

Embodiment 2

[0039] On the basis of Embodiment 1, remove the weight at the end of steel cable A, use an automatic tension device, connect steel cable A to the automatic tension device, collect the force on steel cable A through the control system, and then control the automatic tension device Stretching or loosening is performed to change the force exerted by steel cable A on the pole. The automatic tension device can adopt an electronic spring or an electromagnet to control the force exerted by the steel cable A on the pole by changing the force.

Embodiment 3

[0041] On the basis of Embodiment 1, the steel cable B can be disconnected from the cantilever, and then an automatic rope reel is set on the cantilever, the steel cable B is connected to the automatic rope reel, and the automatic rope reel is controlled by the control system to work The length of the steel cable B can be realized so that the force of the steel cable A changes through the action of the movable pulley, and the force exerted by the steel cable A on the pole can be controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com