Vehicle driving deviated-track automatic measuring system based on laser scanning

A technology of laser scanning and automatic measurement, which is applied in vehicle testing, measuring devices, testing of machine/structural components, etc. It can solve problems such as inability to meet production requirements, complex equipment calibration and troublesome equipment installation for close-range camera detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

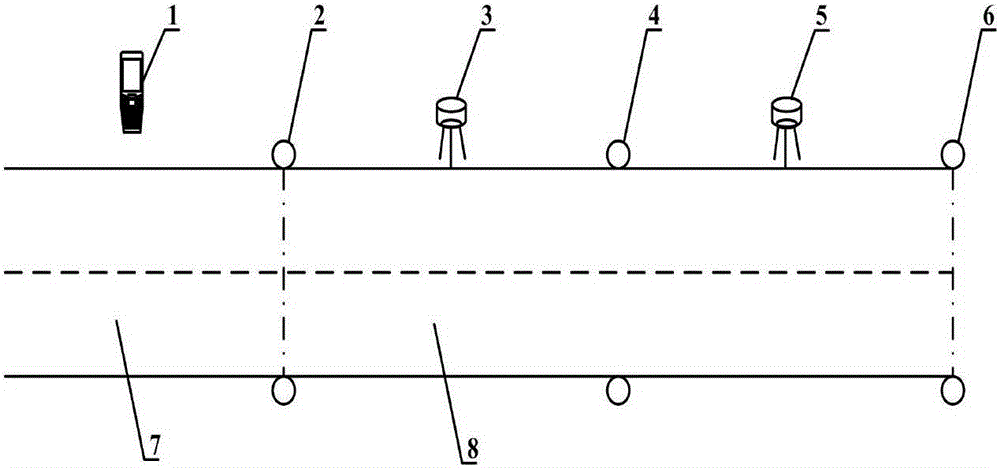

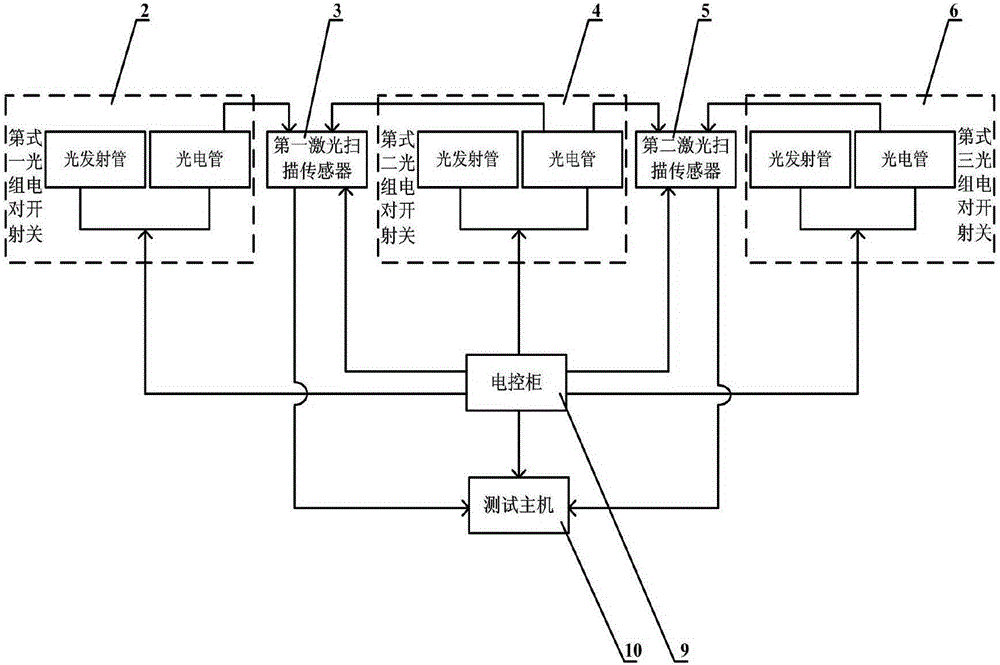

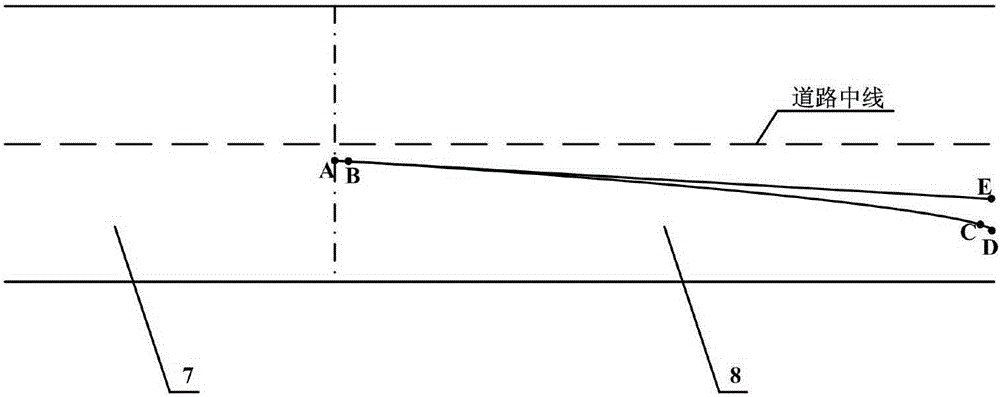

[0050] An automatic measurement system for vehicle running deviation track based on laser scanning. like figure 1 As shown, the automatic measurement system includes a mobile display terminal (1), a first group of beam-type photoelectric switches (2), a first laser scanning sensor (3), a second group of beam-type photoelectric switches (4), a first group of beam-type photoelectric switches (4), Two laser scanning sensors (5), a third group of opposite-beam photoelectric switches, an electric control cabinet (9), a test host (10), a test preparation area (7) and a test area (8).

[0051] like figure 1 As shown, the starting point of the test area (8) is equipped with a first group of beam-type photoelectric switches (2), and a second group of beam-type photoelectric switches (2) are installed at the intermediate position between the start point of the test area (8) and the end point of the test area (8). The switch (4), the end point of the test area (8) is equipped with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com