Conductivity Measurement Method for Reducing Conductor Oxidation

A conductivity and conductor technology, which is used in the field of conductivity measurement to slow down the oxidation of conductors, can solve problems such as wrong water conductivity, wrong conductivity of control unit, and influence on the output current of high-potential conductors, so as to prevent excessive Corrosion, improve service life, slow down the effect of oxidation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical means and structure adopted by the present invention are described in detail with reference to the preferred embodiments of the present invention, and its features and functions are as follows in order to facilitate a complete understanding.

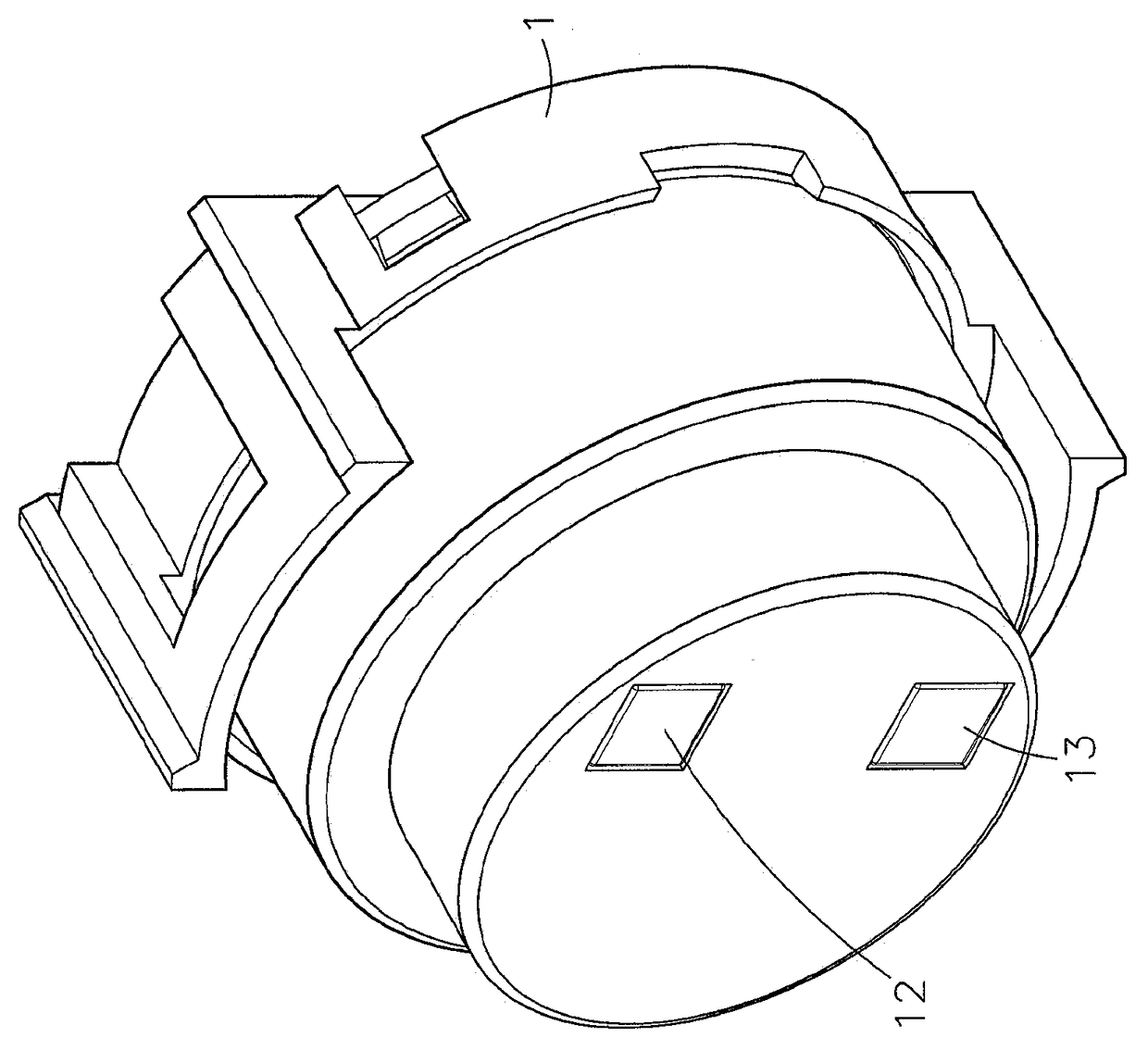

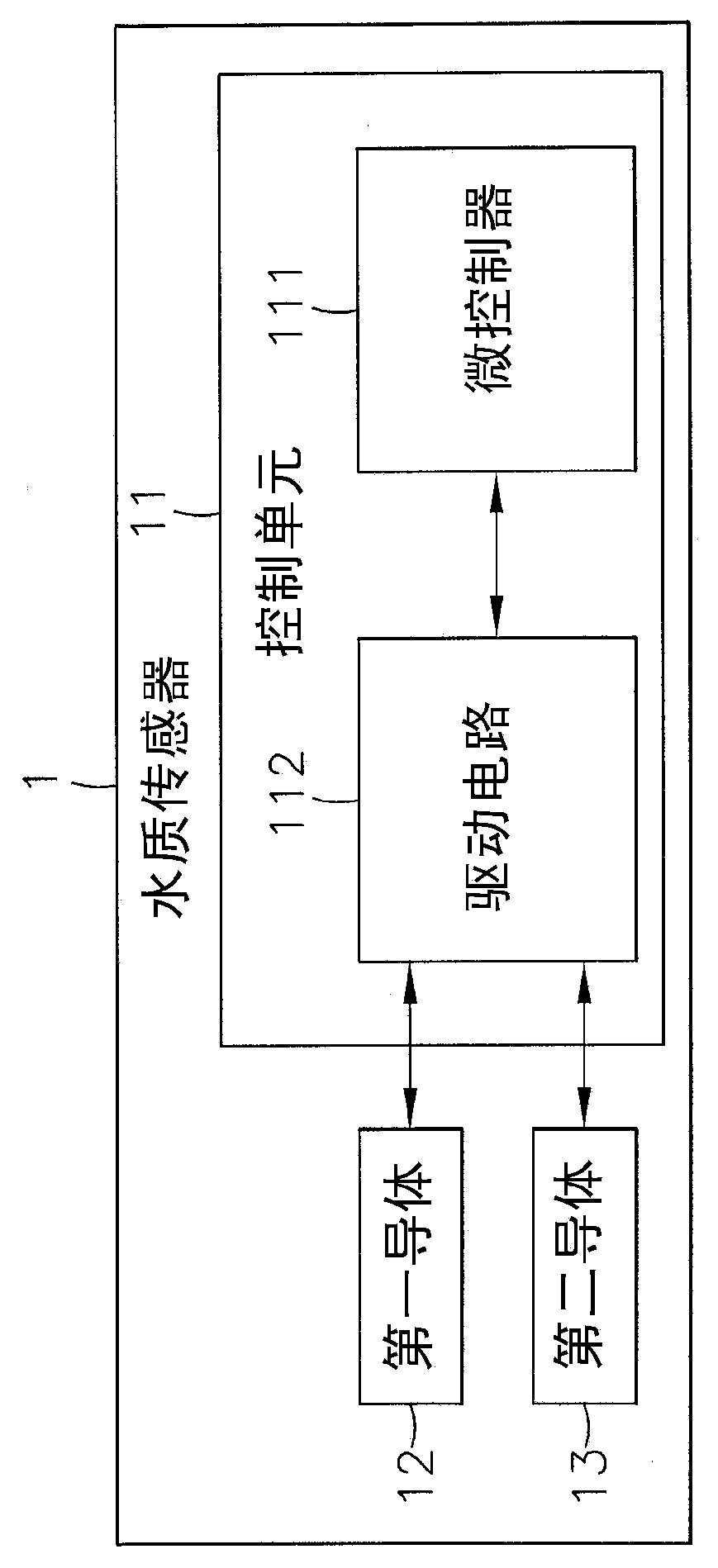

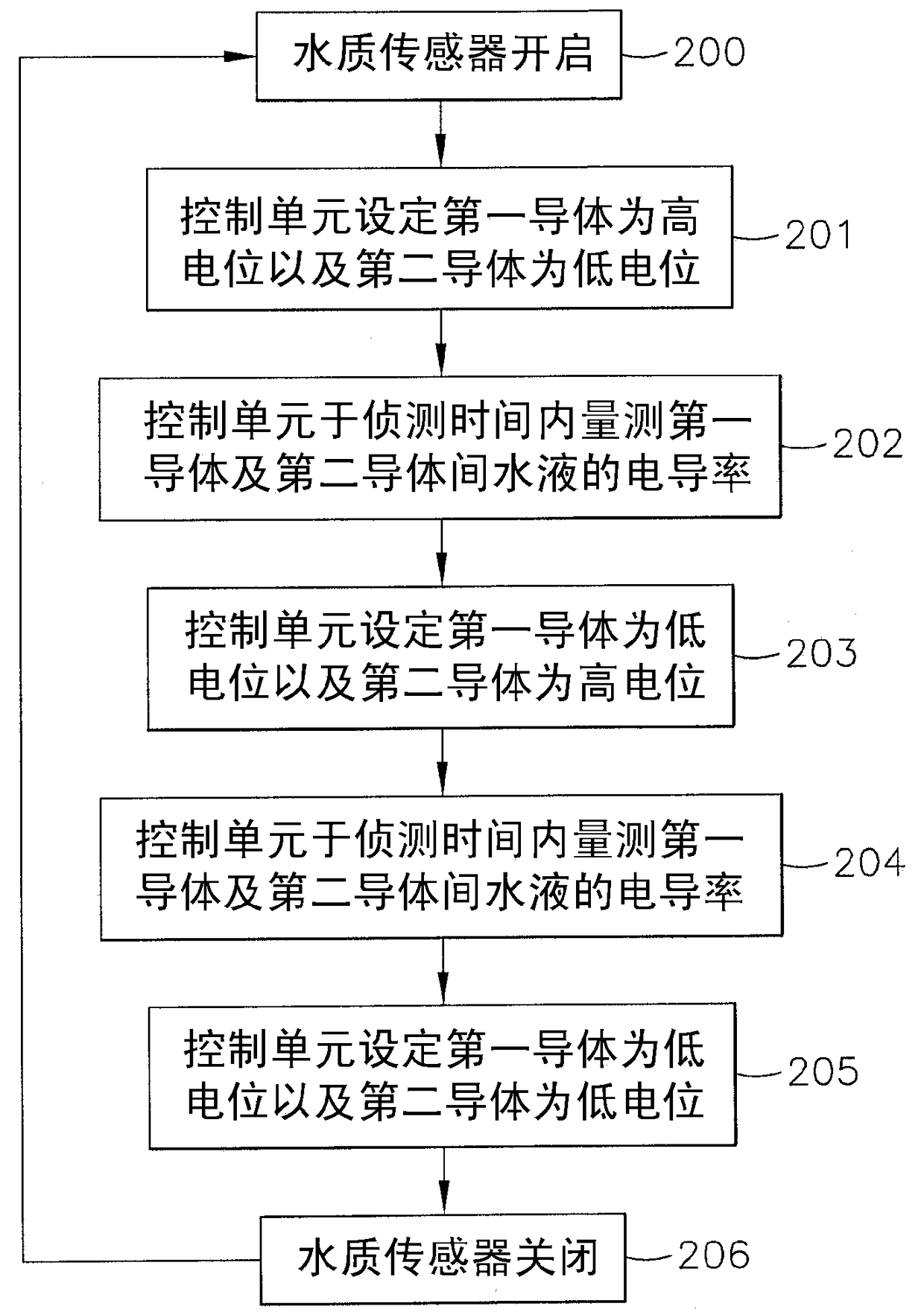

[0029] see figure 1 , figure 2 As shown, it is a three-dimensional appearance diagram of the water quality sensor of the present invention and a schematic circuit diagram of the water quality sensor. It can be clearly seen from the figure that the water quality sensor 1 of the present invention is provided with a control unit 11 inside, and the water quality sensor 1 is located outside. A first conductor 12 and a second conductor 13 electrically connected to the control unit 11 are provided. The aforementioned control unit 11 includes a microcontroller 111 and a driving circuit 112 , and the microcontroller 111 is electrically connected to the driving circuit 112 , and the driving circuit 112 is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com