Remote-control oil cooling special rectification power supply device

A rectifying power supply device and remote control technology, which is applied in the direction of program control, computer control, general control system, etc., can solve problems such as incompleteness and lack of remote control functions of high-power rectifying devices, and achieve comprehensive functions, low power consumption, and stable operation. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

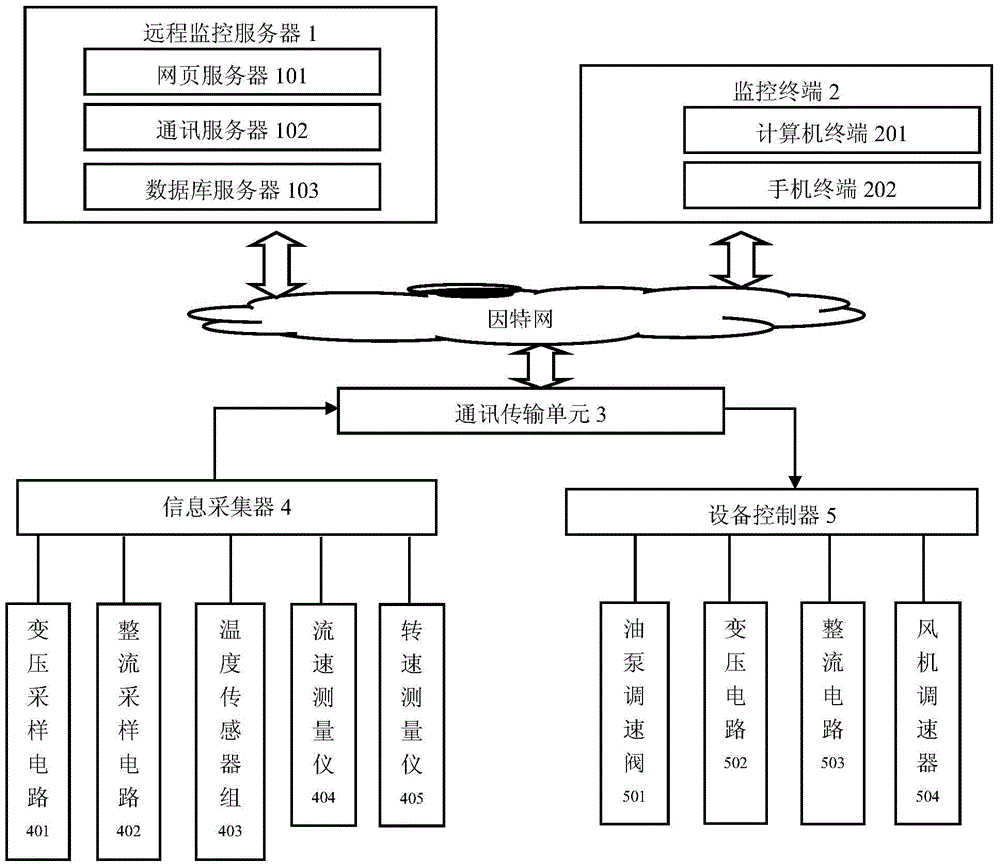

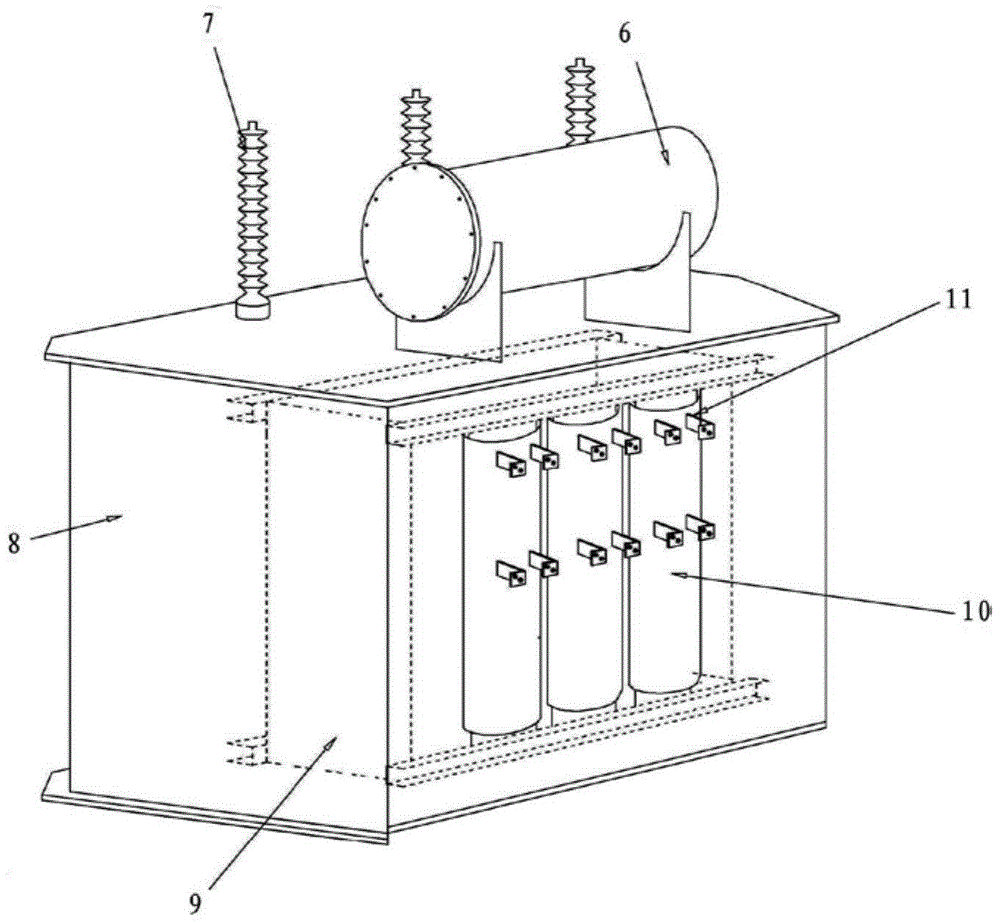

[0035] Example 1 , see Figure 1-5 , the remote control cold oil-type special rectifying power supply device of the present invention comprises a rectifying transformer chamber 8, a rectifying chamber 19, an oil storage chamber 15 and an integrated oil-air circulation cooler 22, and the rectifying chamber and the oil storage chamber are arranged side by side up and down on the rectifying The front side of the transformer room is integrated with the rectifier transformer room; the above rectification device is also equipped with a remote control system, which allows the operator to remotely monitor and control the rectification device through the Internet. The remote control system includes a remote monitoring server 1 and a monitoring terminal 2 , the communication transmission unit 3, the information collector 4 and the equipment controller 5, wherein the monitoring server, the monitoring terminal and the communication transmission unit are all connected to the Internet, and...

Embodiment 2

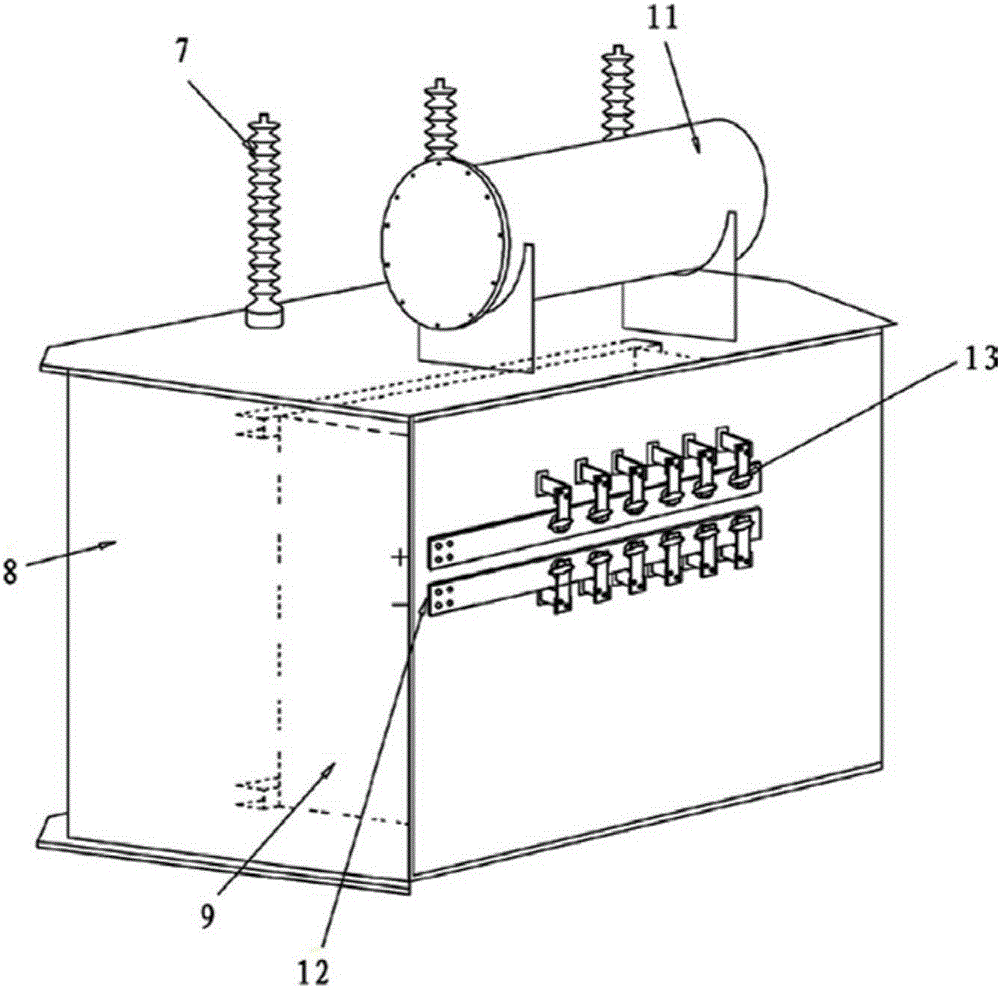

[0045] Example 2 ,like Figure 4 As shown, this embodiment is roughly the same as Embodiment 1, the only difference is that the integrated oil-air circulation cooler 22 is arranged on the outside of the rectifier transformer chamber 8 and the rectification chamber 19, and the integrated oil-air circulation cooler 22 The rectifier transformer chamber 8 and the rectifier chamber 19 are connected with the rectifier transformer chamber 8 and the rectifier chamber 19 through oil pipes and cooling oil pumps respectively connected between the rectifier transformer chamber 8 and the rectifier chamber 19. The rectifier transformer chamber 8 is provided with a rectifier transformer 9 and a rectifier transformer. The transformer coil 10 of 9 is connected and extended to the transformer output copper bar 11 in the rectification chamber 19. The rectification chamber 19 is provided with a silicon rectifier element 13 connected to the transformer output copper bar 11 and a rectifier chamber...

Embodiment 3

[0049] Example 3 ,like Figure 5 As shown, this embodiment is roughly the same as Embodiment 1, the only difference is that the cooling oil is provided with a speed regulating valve, and also includes a base 40, a motor 30, a pump I31, and a pump II32, and the motor 30 is arranged on the base 40. Pump I 31 is connected to the left side of the motor 30 , and pump II 32 is connected to the right side of the motor 30 . The motor 30 includes a motor housing 46, a rotor winding 45 disposed in the inner cavity of the motor housing 46, a stator winding 47 and a rotating shaft 36, and the pump I31 includes a pump body I33, an impeller disposed inside the pump body I33 I34 and the direct coupling frame I38, the direct coupling frame I38 is set on the rotating shaft 36 and the outer side is fixedly connected with the left end surface of the motor housing 46, the pump II32 includes the pump body II43, the impeller II41 arranged inside the pump body II43 and the direct coupling frame I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com