Core electric heating system design method of natural circulation and forced circulation loop system

A technology of electric heating elements and natural circulation, applied in reactors, nuclear power generation, nuclear reactor monitoring, etc., can solve the problems of large geometric scale and flow scale, high cost, etc., achieve high engineering value and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

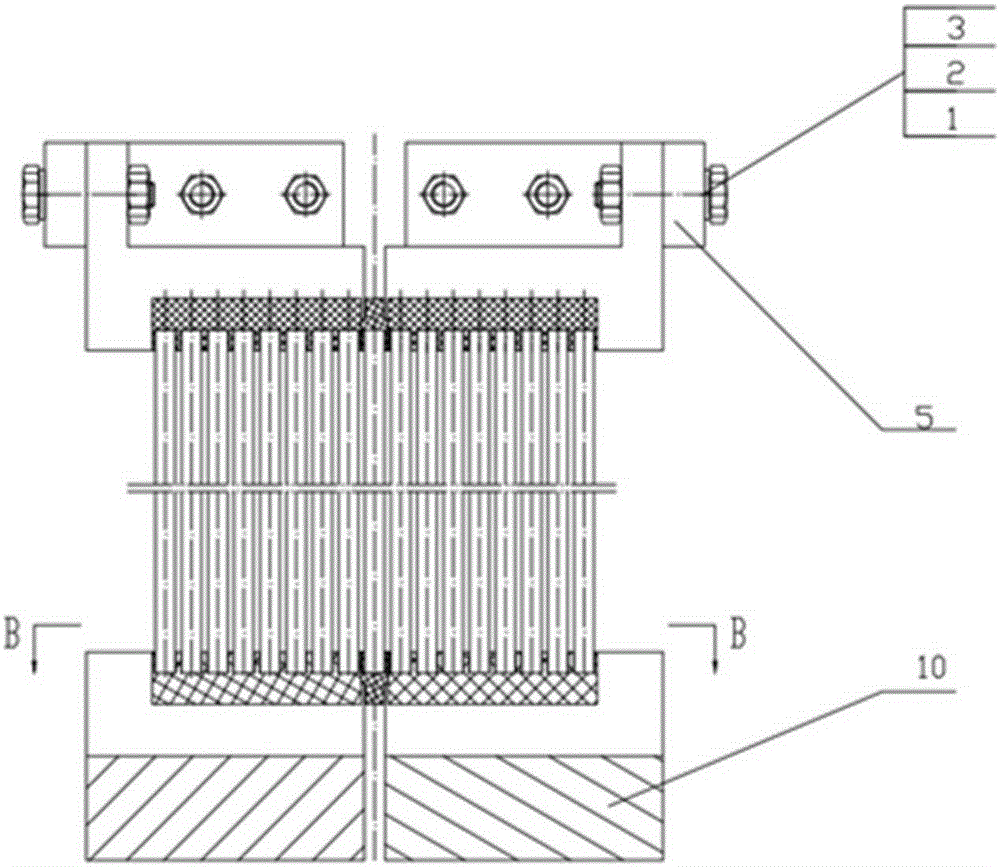

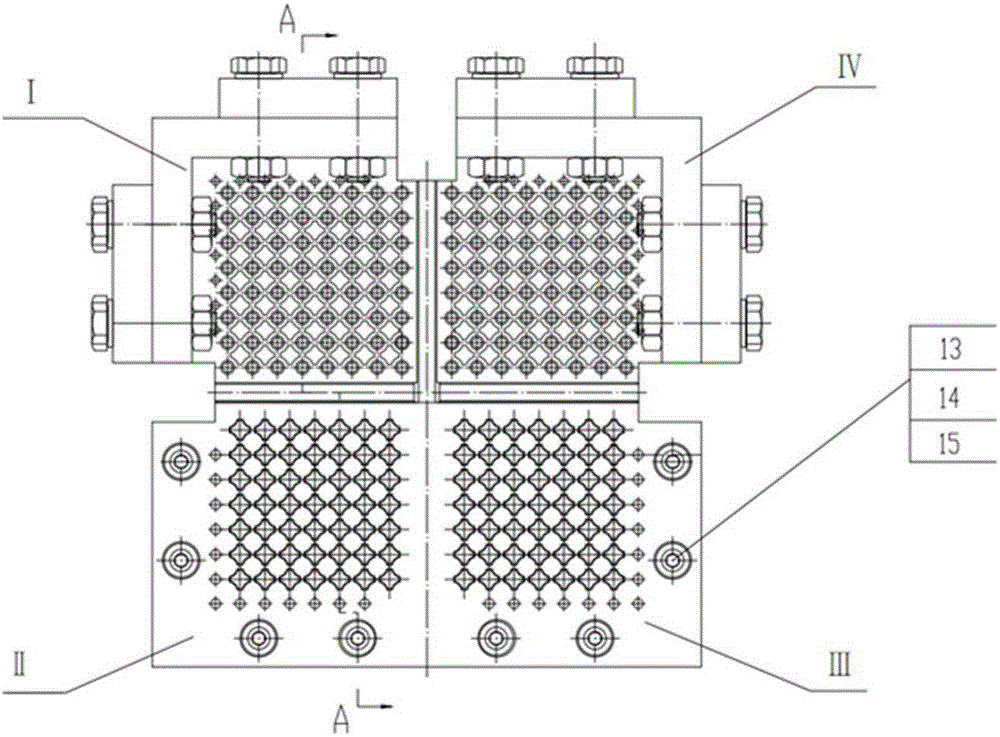

[0024] There are 157 boxes of fuel assemblies in the prototype (ACPR1000), and this core intends to simulate a box of fuel assemblies mainly to simulate the nuclear heat release and resistance characteristics. The specific simulation implementation process is as follows:

[0025] 1. Simulation of nuclear heat release

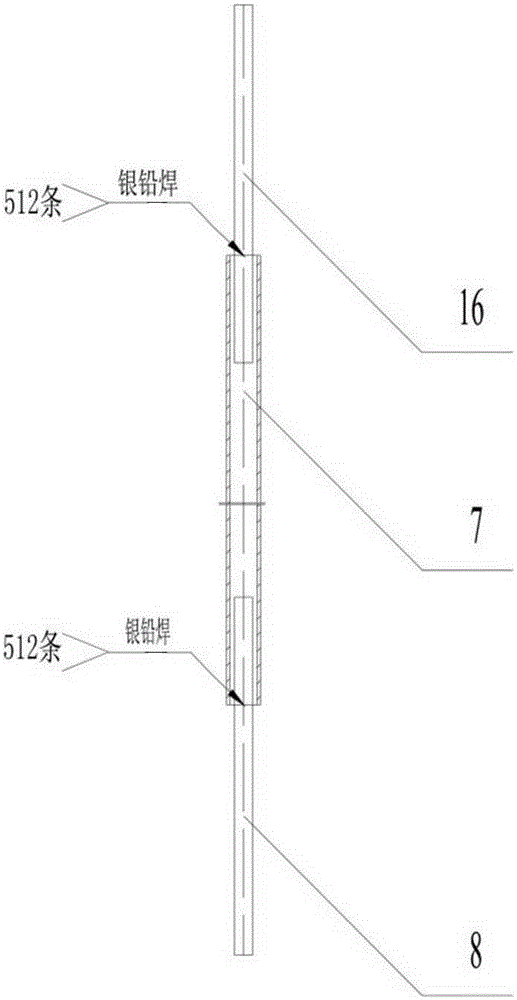

[0026] The electric heating element adopts stainless steel tube as the heating element. The heating method of the electric heating element adopts direct current heating, and each laboratory has a large direct current power supply, which provides the ability to finely adjust the large current, without the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com