Double-sided display substrate and preparation method and display device thereof

一种双面显示、基板的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决影响OLED双面显示屏良率与显示质量、延长OLED双面显示屏生产周期、不利OLED双面显示屏快速推广等问题,达到快速制备与推广、提升良率和显示质量、降低制备成本与能耗成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

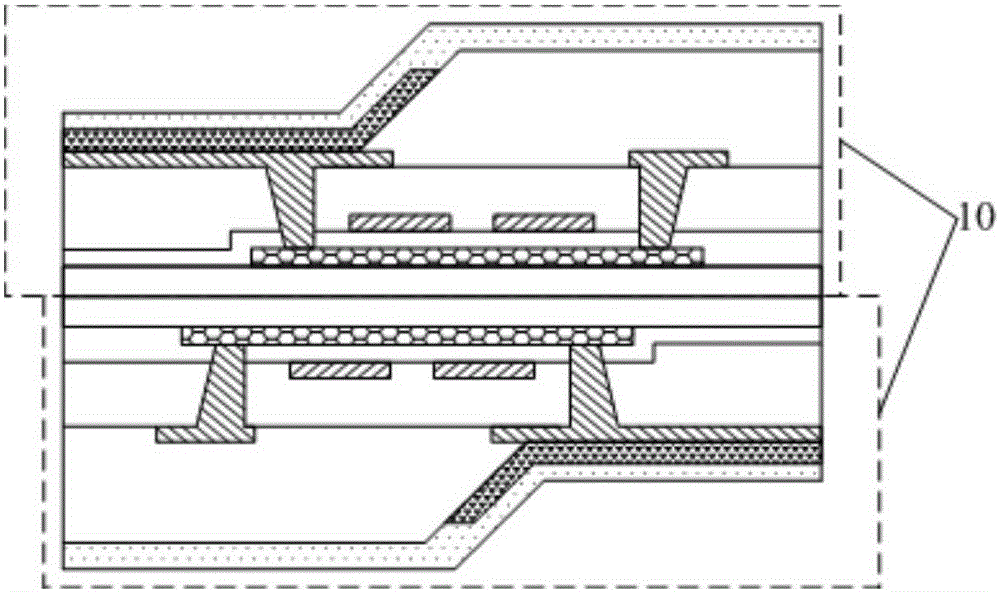

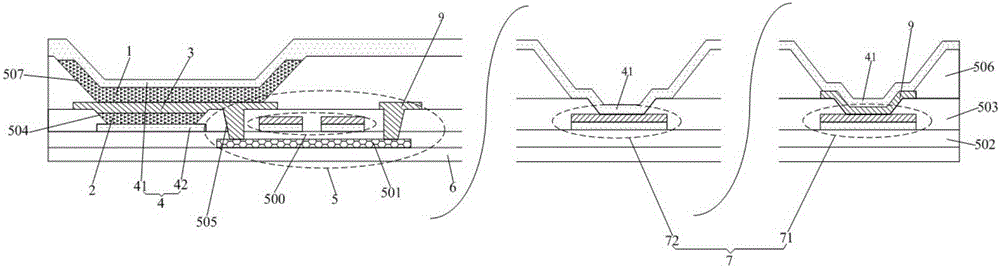

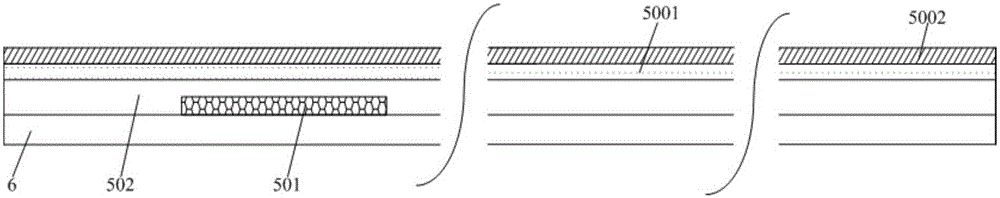

[0051] This embodiment provides a double-sided display substrate, including several sub-pixel units arranged in the pixel area, such as figure 2 As shown, the sub-pixel unit includes a front light emitting layer 1 for front display, a back light emitting layer 2 for back display, a pixel electrode layer 3, a common electrode layer 4 and a driving transistor 5, and the front light emitting layer 1 and the back light emitting layer 2 They are respectively sandwiched between the corresponding pixel electrode layer 3 and the common electrode layer 4, and the driving transistor 5 is used to control the front light emitting layer 1 and the back light emitting layer 2 to emit light, and the common electrode layer 4 corresponding to the back light emitting layer 2 is connected to the drive The gate electrode layer 500 of the transistor 5 is provided in the same layer.

[0052] In this embodiment, the sub-pixel unit includes a driving transistor 5, and the driving transistor 5 is used...

Embodiment 2

[0078] This embodiment provides a double-sided display substrate, which is different from Embodiment 1, as Figure 16 As shown, the sub-pixel unit includes a first drive transistor 51 for controlling the light emission of the front light-emitting layer 1 and a second drive transistor 52 for controlling the light emission of the back light-emitting layer 2. The first drive transistor 51 and the second drive transistor 52 share the same The gate electrode layer 500; the pixel electrode layer 3 includes a first pixel electrode layer 31 corresponding to the front light emitting layer 1 and a second pixel electrode layer 32 corresponding to the back light emitting layer 2, and the front light emitting layer 1 and the back light emitting layer 2 share the same common electrode layer 4. The common electrode layer 4 and the gate electrode layer 500 are arranged on the same layer.

[0079] Such an arrangement enables the first drive transistor 51 and the second drive transistor 52 to c...

Embodiment 3

[0085] This embodiment provides a double-sided display substrate, which is different from Embodiment 1-2, as Figure 17As shown, the sub-pixel unit includes a first drive transistor 51 for controlling the light emission of the front light-emitting layer 1 and a second drive transistor 52 for controlling the light emission of the back light-emitting layer 2. The first drive transistor 51 and the second drive transistor 52 share the same Gate electrode layer 500; the pixel electrode layer 3 includes the first pixel electrode layer 31 corresponding to the front light emitting layer 1 and the second pixel electrode layer 32 corresponding to the back light emitting layer 2, and the common electrode layer 4 includes the first common electrode layer corresponding to the front light emitting layer 1. The electrode layer 41 and the second common electrode layer 42 corresponding to the light-emitting layer 2 on the opposite side, the first common electrode layer 41 , the second common el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com