Dust removal device

A technology of dust removal equipment and dust removal tubes, which is applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., which can solve the problems of severe lung damage, dust remaining in the air, and limited dust adsorption effect, and improve separation efficiency. , Guarantee the separation quality and improve the effect of gas flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

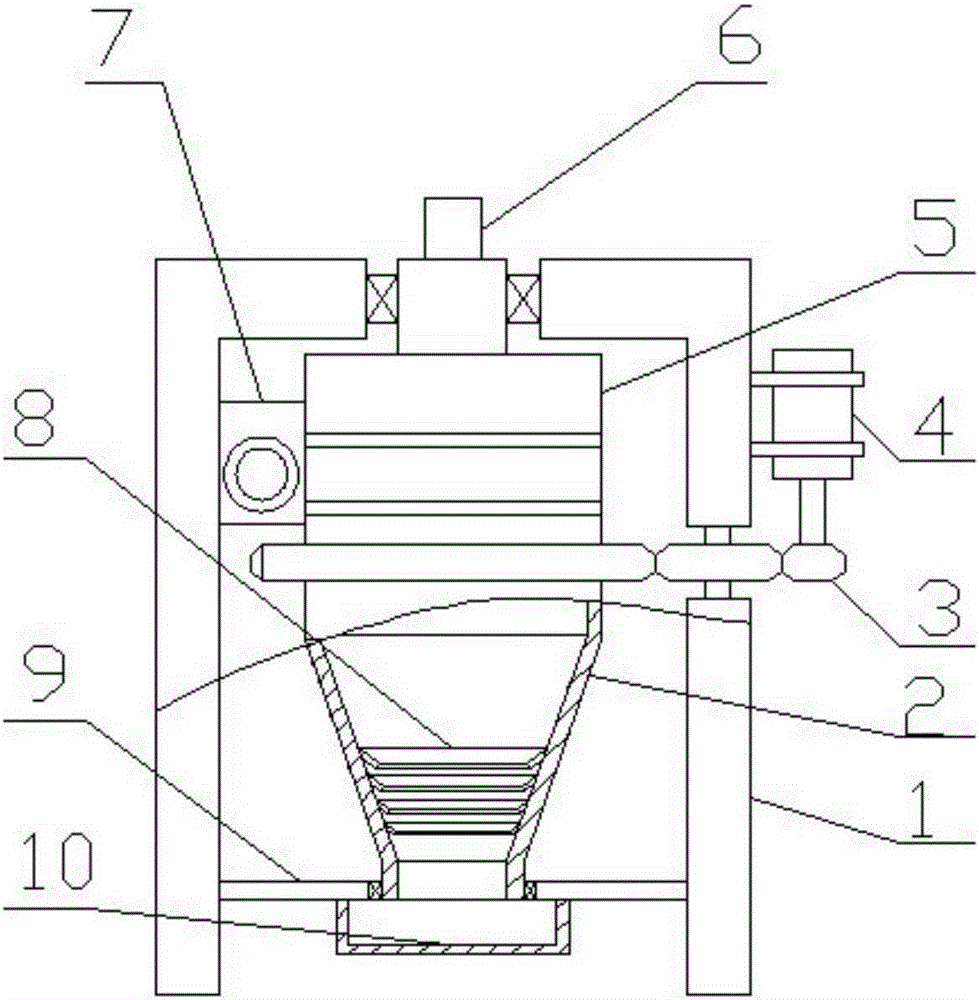

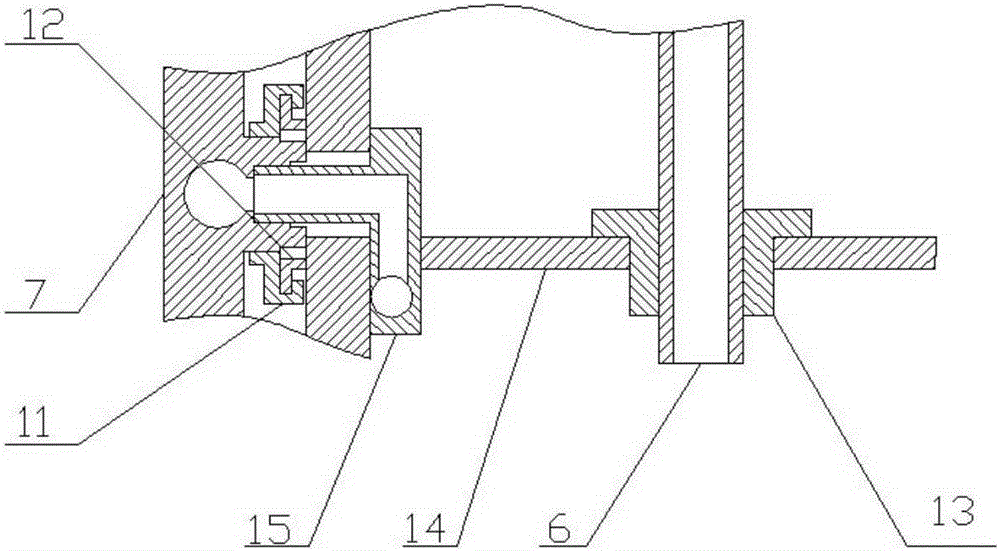

[0018] Such as figure 1 , figure 2 The shown dust removal equipment includes a frame 1, a dust removal pipe 2, a shield 5, an exhaust pipe 6, an air intake pipe 7, a nozzle 15, a liner 14 and a motor 4, and the upper section of the dust removal pipe 2 is a large cylinder shaped cavity, the middle section is a conical cavity, and the lower section is a small cylindrical cavity. The upper, middle and lower sections of the dust removal pipe 2 transition smoothly, and the shield 5 is installed on the frame 1. The cover 5 is connected to the upper edge of the dust removal pipe 2, the exhaust pipe 6 is installed at the center of the upper top surface of the shield 5, the air inlet pipe 7 is installed on the frame 1, and the air inlet pipe 7 is connected to the nozzle 15 connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com