Fluidized bed type organic exhaust purification method and device

A technology of organic waste gas and purification device, which is applied in the direction of combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., which can solve the problems of high cost, low efficiency, and complicated process of purifying organic waste gas, so as to improve the use efficiency , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

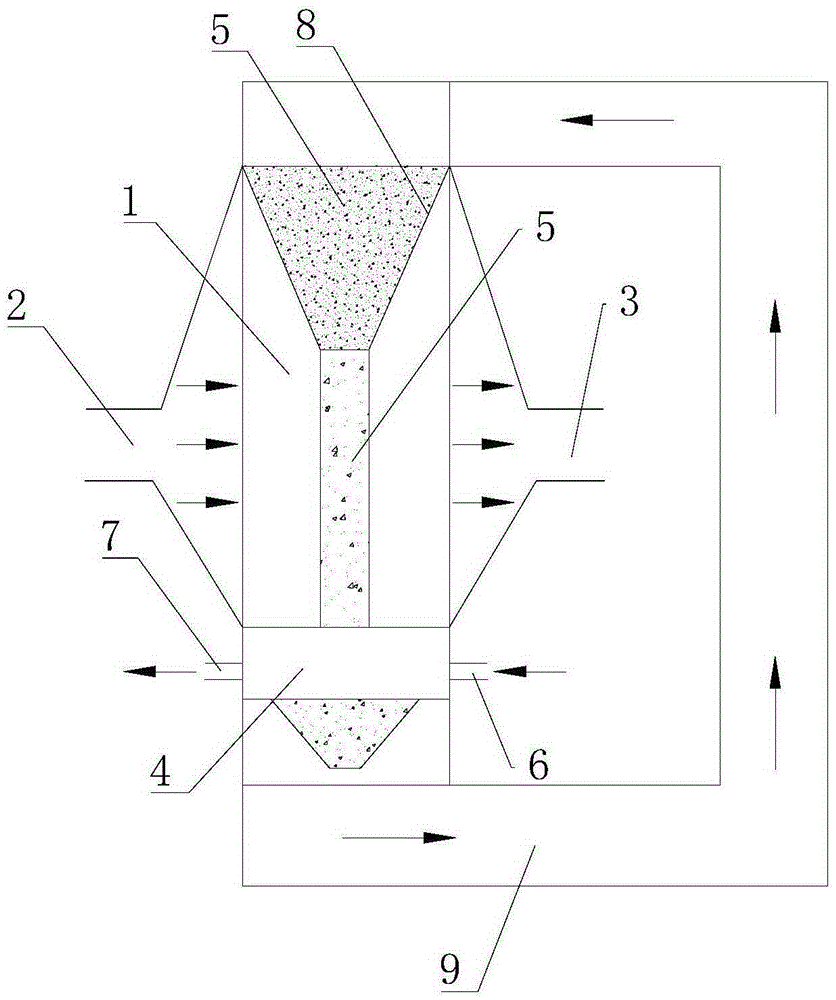

[0030] The present invention proposes a fluidized bed organic waste gas purification method, and at the same time proposes a fluidized bed organic waste gas purification device. The method and device can realize simultaneous adsorption and desorption when treating organic waste gas, and the process and structure Simple, greatly reduces the cost of exhaust gas purification, and improves the efficiency of exhaust gas purification.

[0031] The fluidized bed organic waste gas purification method of this embodiment includes the following steps:

[0032] 1) Adsorption, the waste gas passes through the adsorption chamber in the horizontal direction, and the organic waste gas is adsorbed by the adsorption medium moving from top to bottom in the adsorption chamber;

[0033] 2) Desorption, the adsorption medium with organic waste gas falls into the desorption chamber for desorption, and the desorbed organic waste gas is taken out of the desorption chamber by the carrier gas for treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com