Fishbone needle type cathode line for wet type electric precipitator

A wet electrostatic precipitator, cathode line technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of prone to corona blockage, inflexible design, lack of cathode line discharge performance, etc. Halo closed, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

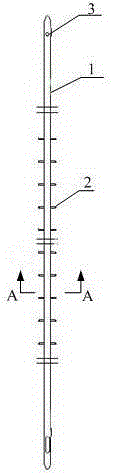

[0022] A herringbone needle-type cathode wire for a wet electrostatic precipitator, comprising a cathode rod, a plurality of stainless steel rings are sheathed on said cathode rod, and N herringbone needles are fixedly connected to one stainless steel ring, and the adjacent herringbone The included angle between the needles is 360° / N, where N is a positive integer; N fishbone needles on adjacent stainless steel rings are arranged in random order; the discharge tip of each fishbone needle is spherical. Both ends of the cathode rod are provided with positioning holes.

Embodiment 2

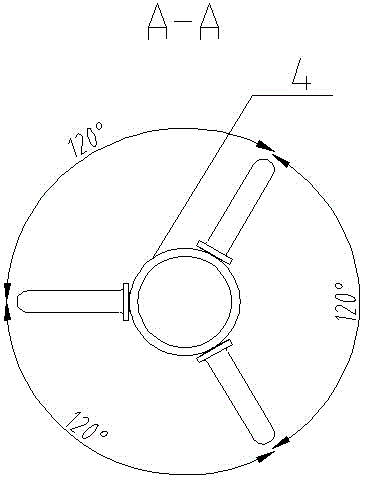

[0024] Such as figure 2 As shown, this embodiment is improved on the basis of embodiment 1. The difference from embodiment 1 is that three herringbone needles are fixedly connected to the one stainless steel ring, and the included angle between adjacent herringbone needles is is 120°.

Embodiment 3

[0026] This embodiment is improved on the basis of embodiment 1. The difference from embodiment 1 is that the inner diameters of the several stainless steel rings are equal to the outer diameter of the cathode rod, and the outer diameters of the several stainless steel rings are all equal. Make sure that the stainless steel ring fits firmly on the cathode rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com