Method for producing hydroxylamine hydrochloride by using industrial tail gas absorption waste liquid

A technology for industrial exhaust gas and hydroxylamine hydrochloride, which is applied in the directions of hydroxylamine, nitrogen and non-metallic compounds, can solve the problems of increased cost, high requirements on the floor space of sewage treatment plants and disadvantages, and achieves the effect of saving costs and reducing industrial water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take a 4000L reaction tank as an example, and the feeding amount is shown in Table 1.

[0032] Table 1 Feeding amount of Example 1

[0033] Name

Industrial exhaust gas absorbs waste liquid

Feeding amount (Kg)

37.2

3100

310

837

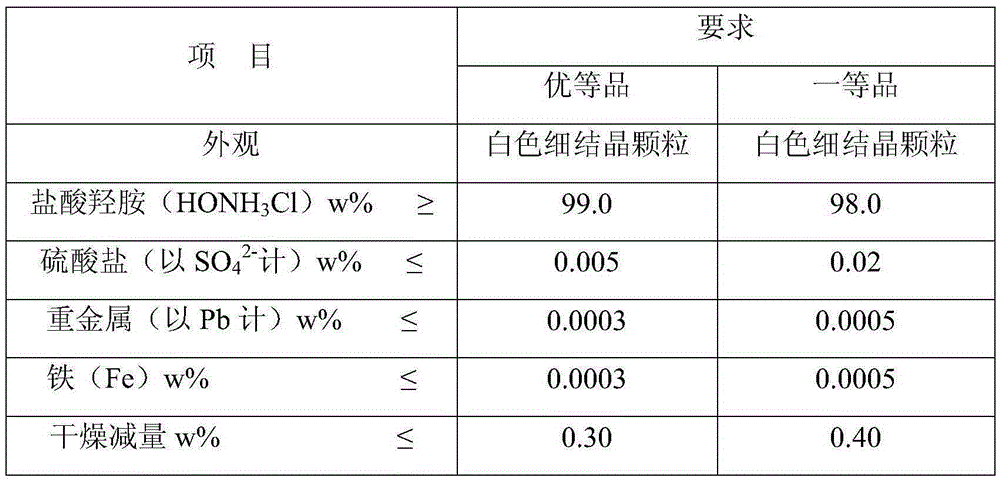

[0034] Table 2 Hydroxylamine Hydrochloride Quality Standard: (HG / T3736-2013)

[0035]

[0036] The quality of hydroxylamine hydrochloride prepared in Example 1 is shown in Table 3.

[0037] Table 3 Quality of Hydroxylamine Hydrochloride

[0038] Item

Embodiment 2

[0040] Take a 4000L reaction tank as an example, the feeding amount is shown in Table 4.

[0041] Table 4 Feeding amount of Example 2

[0042] Name

Industrial exhaust gas absorbs waste liquid

Feeding amount (Kg)

37.8

2700

270

1026

[0043] The quality of hydroxylamine hydrochloride prepared in Example 2 is shown in Table 5.

[0044] Table 5 Hydroxylamine Hydrochloride Quality

[0045] Item

Embodiment 3

[0047] Take a 4000L reaction tank as an example, and the feeding amount is shown in Table 6.

[0048] Table 6 Feeding amount of Example 3

[0049] Name

Industrial exhaust gas absorbs waste liquid

Feeding amount (Kg)

36.4

2800

560

756

[0050] The quality of hydroxylamine hydrochloride obtained in Example 3 is shown in Table 7.

[0051] Table 7 Hydroxylamine Hydrochloride Quality

[0052] Item

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com