A steam waste heat recovery device

A technology of recovery device and steam waste heat, which is applied in steam generation, preheating, feed water heater, etc., can solve the problems of high boiler fuel consumption, air pollution, and high industrial water consumption, so as to reduce industrial water consumption, improve thermal efficiency, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

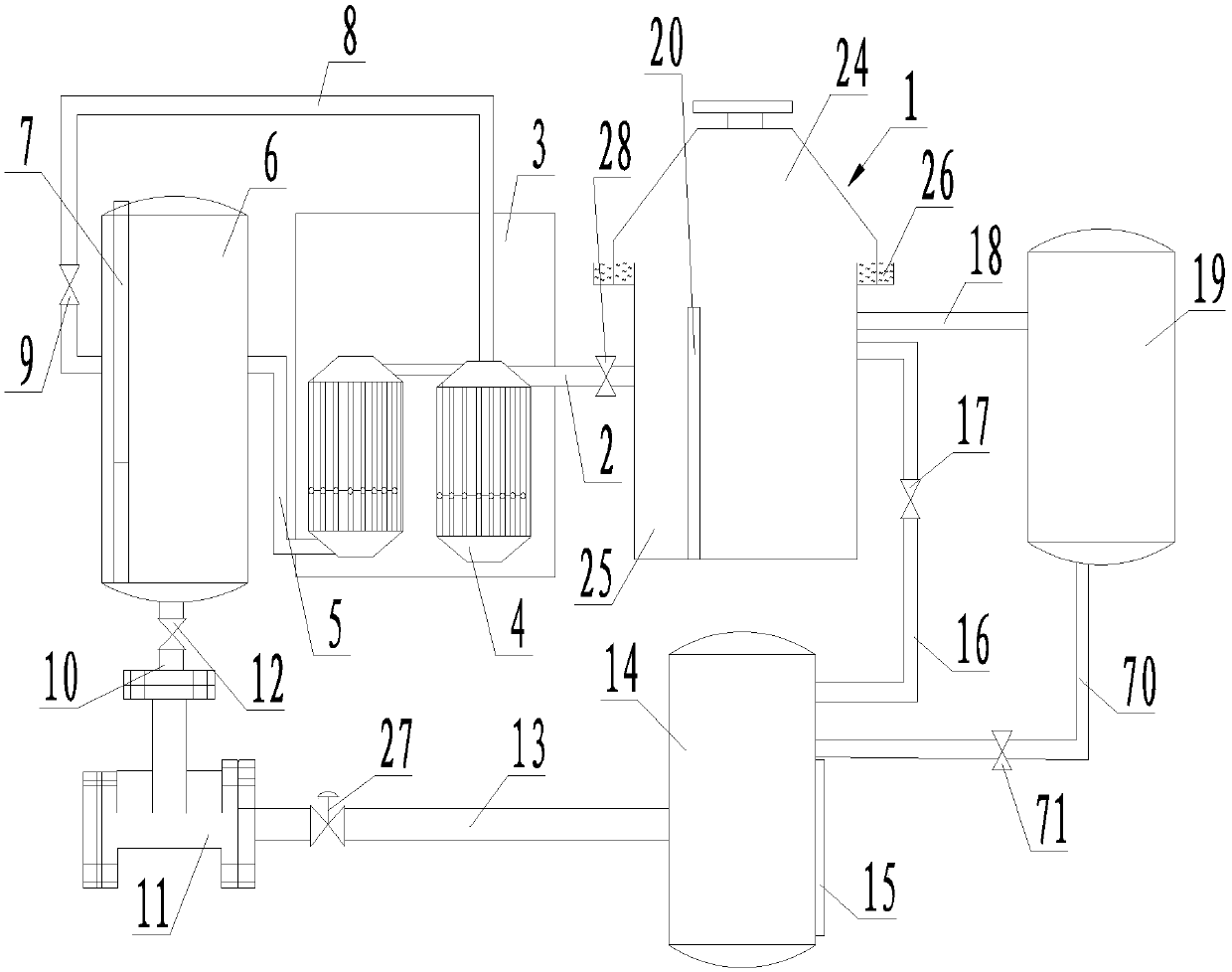

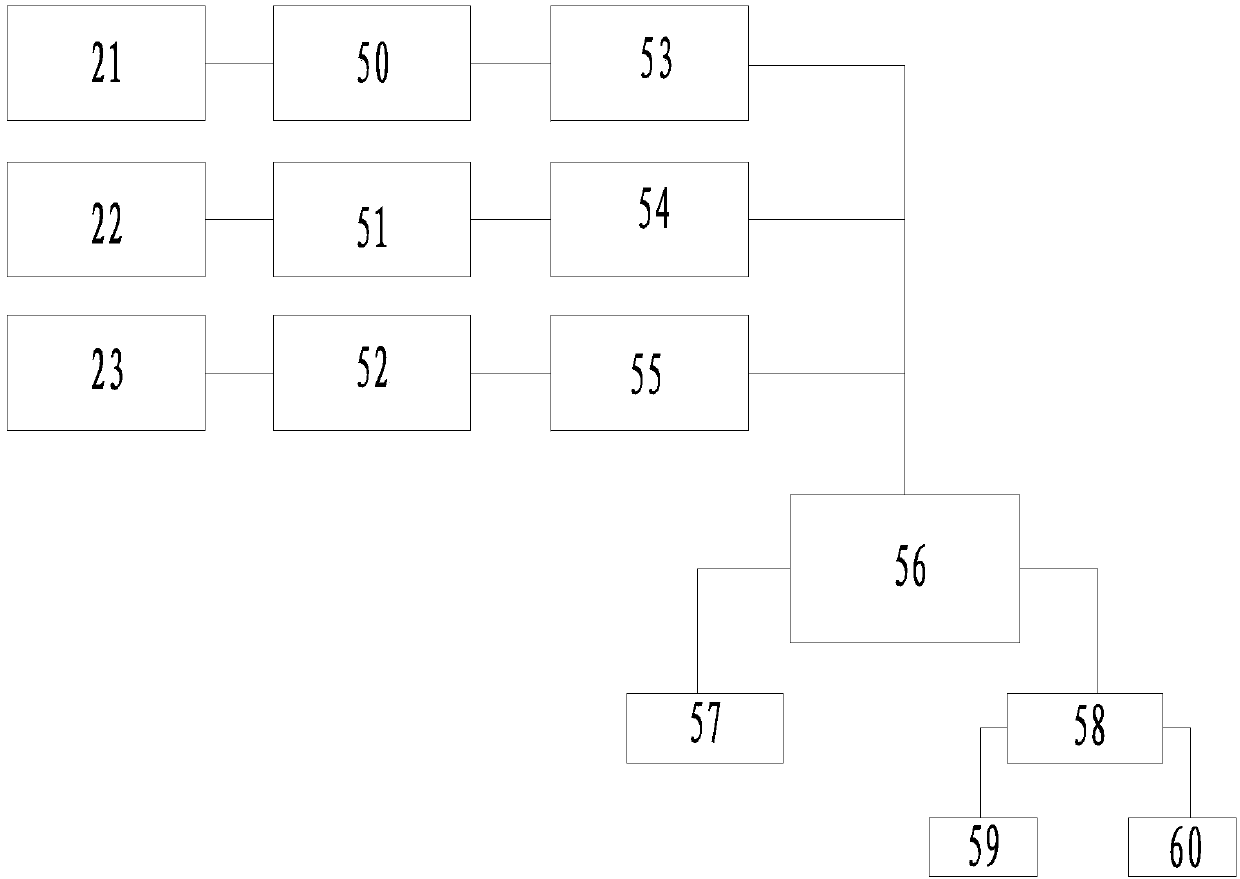

[0027] The present invention will be further explained below in conjunction with the drawings and embodiments:

[0028] Such as Figure 1 to Figure 2 As shown, a steam waste heat recovery device includes a boiler 1, and the boiler 1 is connected to a steam room 3 through a first connecting pipe 2, wherein the first connecting pipe 2 is provided with a fourth switch valve 28. At least one heat exchanger 4 is provided in the steam room 3, and the number of heat exchangers 4 used in this embodiment is two.

[0029] The steam room 3 is connected to the hot water storage tank 6 through the second connecting pipe 5, and the hot water storage tank 6 is provided with a temperature measuring device 7; in order to effectively improve the accuracy of temperature detection, in this embodiment, the temperature measuring device 7 The bottom of the long strip temperature measuring device 7 is attached to the bottom of the hot water storage tank 6, and the top of the temperature measuring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com