Dry vibration material used in tundish, and preparation method thereof

A dry vibrating material and tundish technology, which is applied in the field of monolithic refractory materials, can solve the problems that magnesia-chrome bricks cannot be replaced, and achieve the effects of saving mineral resources and energy, reducing environmental pollution, and reducing steelmaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

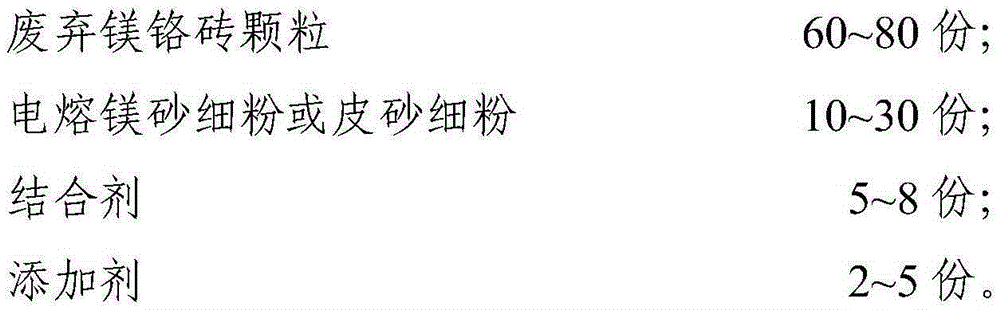

Method used

Image

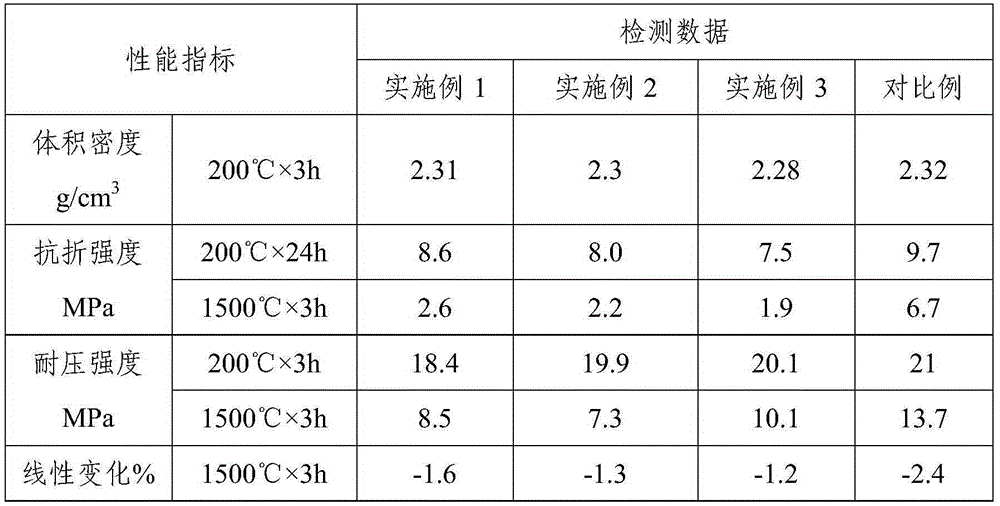

Examples

Embodiment 1

[0026] This embodiment provides a dry vibrating material, which is composed of the following raw materials by weight percentage: 70% of waste magnesia-chrome brick particles, 20% of fused magnesia fine powder, 6% of maltose, and 4% of water glass.

[0027] The present embodiment provides the preparation method of the dry vibrating material, which includes the following steps: taking each raw material in proportion; putting the fused magnesia fine powder and water glass into a small mixer and mixing for 10 minutes to obtain a finely mixed powder powder, and set aside; then put the mixed fine powder and other raw materials into a blender, stir evenly, vibrate and shape, bake at 150°C, and demould to obtain.

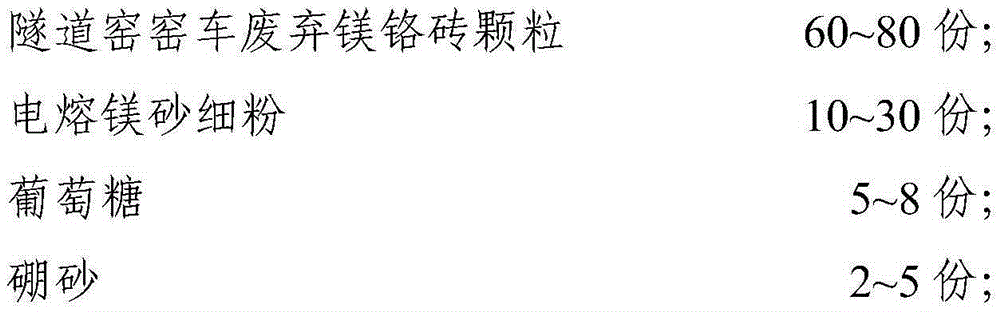

Embodiment 2

[0029] This embodiment provides a dry vibrating material, which is composed of the following raw materials by weight percentage: 80% of waste magnesia-chrome brick particles, 11% of leather sand fine powder, 7% of glucose, and 2% of borax.

[0030] The present embodiment provides the preparation method of the dry vibrating material, comprising the following steps: taking each raw material in proportion; putting leather sand fine powder and borax into a small mixer and mixing for 10 minutes to obtain a fine powder mixed for later use and then put the mixed fine powder and other raw materials into a blender, stir evenly, vibrate and shape, bake at 350°C, and demould to obtain.

Embodiment 3

[0032] This embodiment provides a dry vibrating material, which is composed of the following raw materials by weight percentage: 60% of waste magnesia-chrome brick particles, 27% of fused magnesia fine powder, 8% of sucrose, and 5% of white clay.

[0033] This embodiment provides the preparation method of the dry vibrating material, which includes the following steps: taking each raw material in proportion; putting the fused magnesia fine powder and white clay into a small mixer and mixing for 10 minutes to obtain a finely mixed powder powder, and set aside; then put the mixed fine powder and other raw materials into a blender, stir evenly, vibrate and shape, bake at 250°C, and demould to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com