High temperature-resistant regenerated polyester fiber laminated sheet material for engine compartment and preparation method thereof

A technology of recycled polyester and engine compartment, applied in fiber processing, chemical instruments and methods, layered products, etc., can solve the problems of general noise and vibration reduction effect in the car room, affecting the safety of car driving, poor sound insulation effect, etc. The effect of reducing traffic accidents, improving safe driving and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the high temperature resistant regenerated polyester fiber laminated sheet of the engine compartment of the present invention comprises the following steps:

[0031] 1) Preparation of recycled polyester fiber sheet;

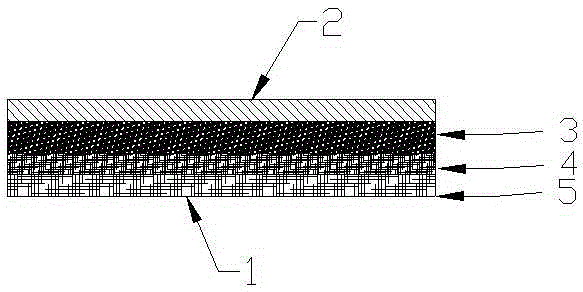

[0032] 2) Cover the surface of the compact layer 3 of the recycled polyester fiber sheet with aluminum foil;

[0033] 3) Heating the temperature to 100°C, and then laminating the surface of the aluminum foil, so that the recycled polyester fiber sheet and the aluminum foil are firmly bonded, that is, a high temperature resistant recycled polyester fiber laminated sheet for the engine compartment is obtained.

[0034] Aluminum foil has the characteristics of high temperature resistance, which meets the requirements of combustion characteristics of automotive interior parts.

[0035] Wherein, the preparation method of regenerated polyester fiber sheet comprises:

[0036] 1) Recycling scrapped polyester fiber products, cleaning and...

Embodiment 2

[0041] The preparation method of the high temperature resistant regenerated polyester fiber laminated sheet of the engine compartment of the present invention comprises the following steps:

[0042] 1) Preparation of recycled polyester fiber sheet;

[0043] 2) Cover the surface of the compact layer 3 of the recycled polyester fiber sheet with aluminum foil;

[0044] 3) Heating the temperature to 120°C, and then laminating the surface of the aluminum foil, so that the recycled polyester fiber sheet and the aluminum foil are firmly bonded, that is, a high temperature resistant recycled polyester fiber laminated sheet for the engine compartment is obtained.

[0045] Aluminum foil has the characteristics of high temperature resistance, which meets the requirements of combustion characteristics of automotive interior parts.

[0046] Wherein, the preparation method of regenerated polyester fiber sheet comprises:

[0047] 1) Recycling scrapped polyester fiber products, cleaning and...

Embodiment 3

[0052] The preparation method of the high temperature resistant regenerated polyester fiber laminated sheet of the engine compartment of the present invention comprises the following steps:

[0053] 1) Preparation of recycled polyester fiber sheet;

[0054] 2) Cover the surface of the compact layer 3 of the recycled polyester fiber sheet with aluminum foil;

[0055]3) Heating the temperature to 130°C, and then laminating the surface of the aluminum foil, so that the recycled polyester fiber sheet and the aluminum foil are firmly bonded, that is, a high temperature resistant recycled polyester fiber laminated sheet for the engine compartment is obtained.

[0056] Aluminum foil has the characteristics of high temperature resistance, which meets the requirements of combustion characteristics of automotive interior parts.

[0057] Wherein, the preparation method of regenerated polyester fiber sheet comprises:

[0058] 1) Recycling scrapped polyester fiber products, cleaning and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com