Construction device and construction method of bored cast-in-place static pressure pipe pile with enlarged bottom

A technology of drilling device and construction device, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of complex construction, large environmental pollution and high cost, and achieve reasonable structural design, simple construction process and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

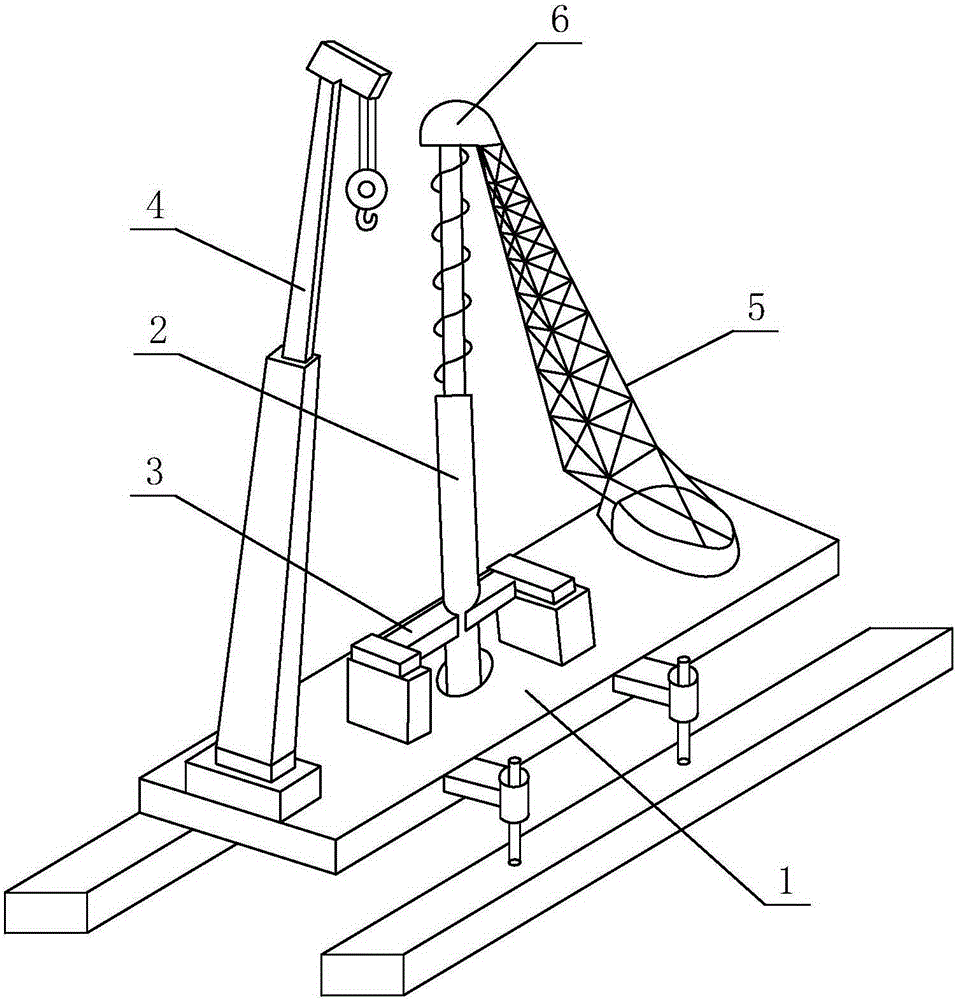

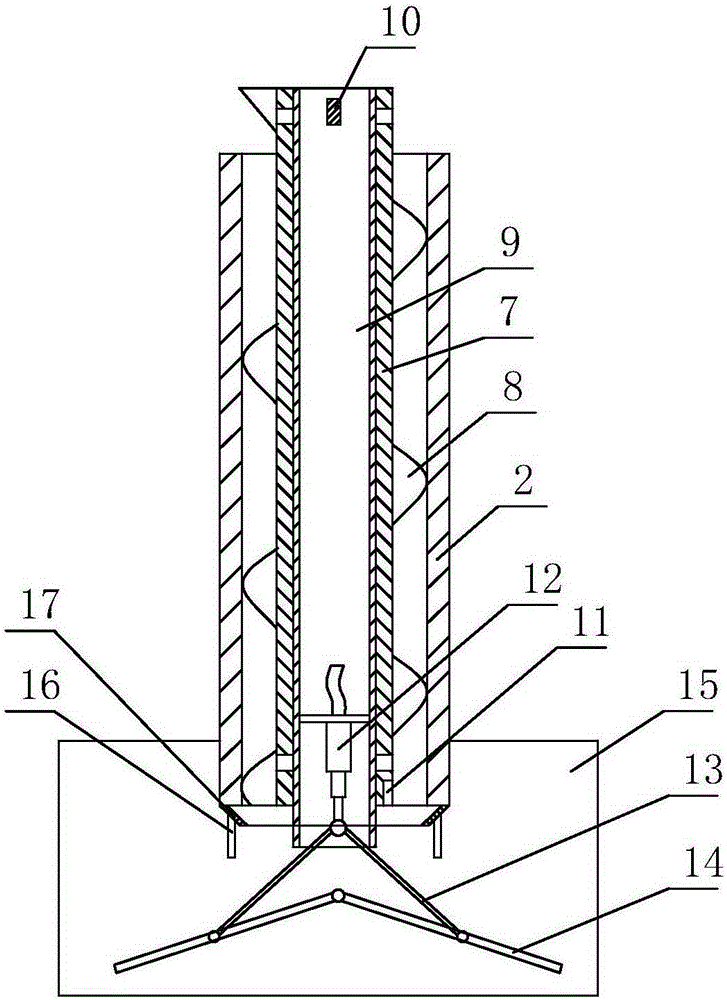

[0030] Such as Figure 1-2 As shown, a static pressure pipe pile construction device for drilling bottom expansion grouting includes a static pressure machine 1, on which a clamper 3 for clamping a pipe pile 2 is provided, and on both sides of the clamper 3 The static press 1 is respectively provided with a rotary crane 4 and a rotary truss 5, and on the top of the rotary truss 5 is provided a drilling rig 6 with the output shaft facing downwards, and the output shaft of the drilling rig 6 is connected with a vertically arranged drilling device, so The drilling device includes a helical casing 7 with a helical blade 8, and a drill core pipe 9 is arranged in the helical casing 7, and the helical casing 7 and the drill core pipe 9 are fixedly connected by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com