Construction Method of Mountain Tunnel with Horizontal Pre-reinforcement Treatment

A tunnel construction, horizontal technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as weathering cannot be prevented, surrounding rocks cannot be closed, cracked rocks peel off, etc., and the construction method is simple, surface subsidence is avoided, The effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

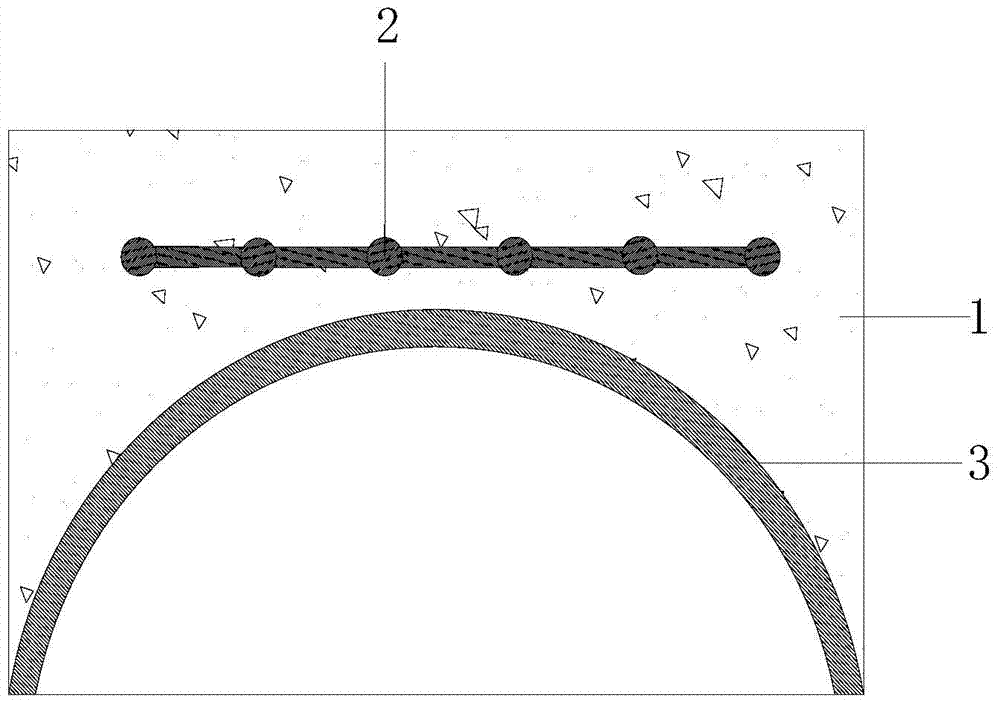

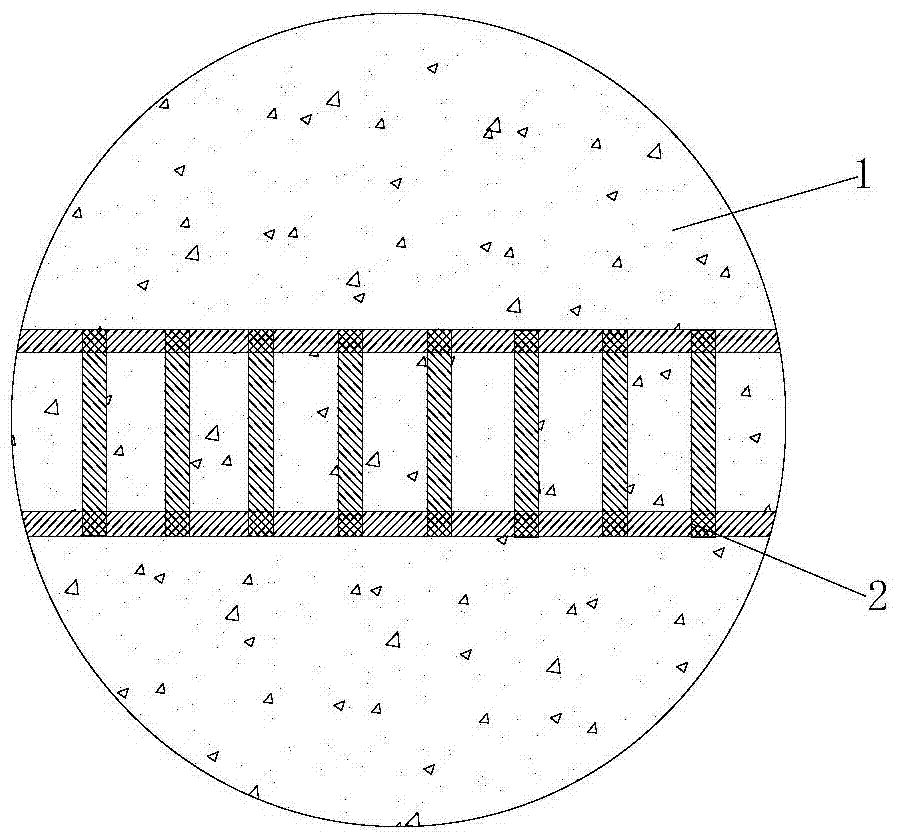

[0017] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a top view of the horizontal section of cast-in-situ piles distributed in the rock and soil layer of the mountain.

[0018] The mountain tunnel construction method of the horizontal pre-reinforcement treatment of the present embodiment, the mountain tunnel construction method of the horizontal pre-reinforcement treatment of the present invention, before the tunnel excavation construction, the rock and soil layer 1 above the tunnel excavation contour line 3 is drilled horizontally The cast-in-place pile 2 is pre-reinforced to achieve the purpose of stabilizing the soil; the cement concrete can penetrate into the gaps in the rock-soil layer 1 of the mountain body, and together with the cast-in-place pile 2 forms the supporting skeleton of the rock-soil layer 1 of the mountain body, forming a structure with a certain strength and The overall composite rock-soil layer 1 improves the sel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap