Borehole Layout Method for Gas Drainage During Initial Mining and Recovery of Fully Mechanized Mining Face with Large Mining Height

A fully-mechanized mining face and gas drainage technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problem of high-level drilling not functioning, pressure relief gas rushing, and large gas gushing out of goafs, etc. problems, to achieve the effect of increasing the drainage volume and utilization rate, reducing the amount of gas gushing out, and reducing the gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

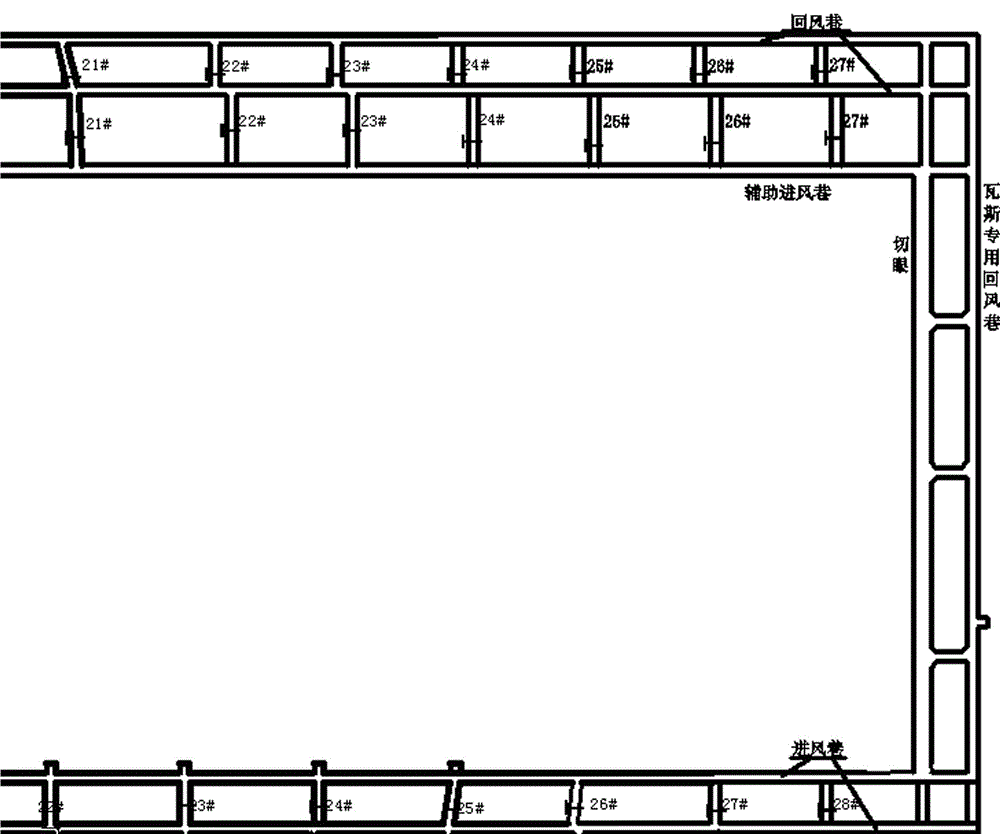

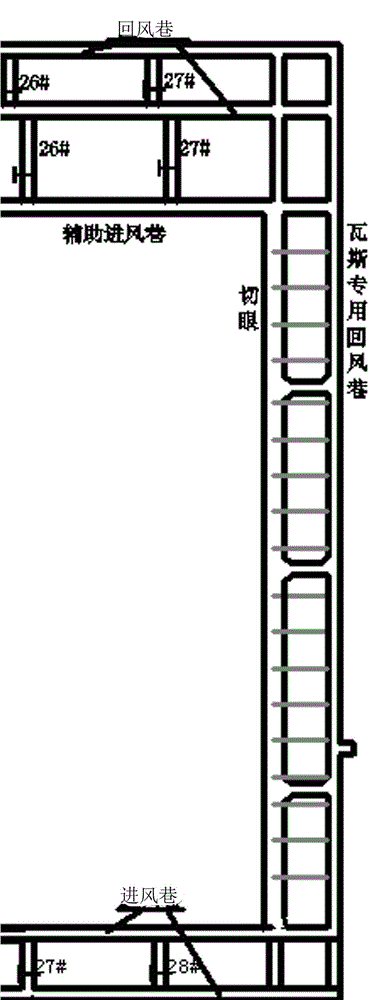

[0031] The roadway layout of fully mechanized mining face with large mining height is as follows: figure 1 As shown, it is generally arranged as a "three-inlet and two-return" ventilation system. The entire coal mining area is composed of five roadways, gas return airways, and cutouts.

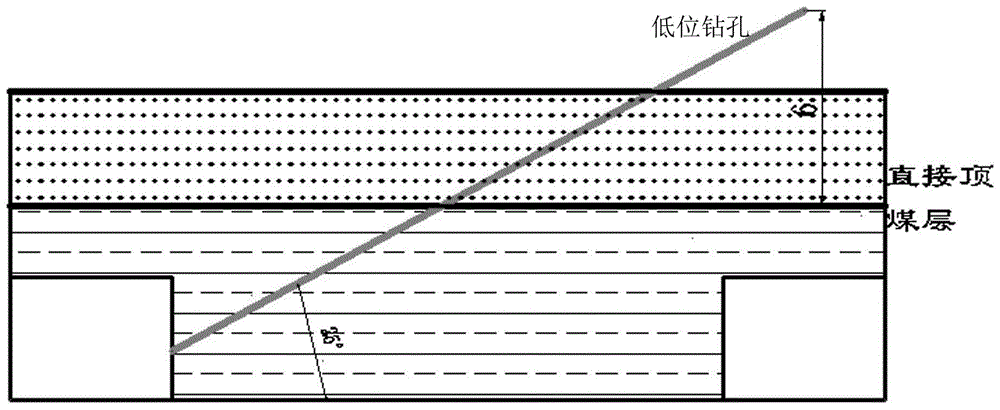

[0032] The specific implementation method of low-level drilling: the low-level drilling is relatively short, and ordinary drilling rigs are used to drill holes from the special gas return airway to the roof of the cut hole. 6±1m, 30±2m in length, and 10~20m between adjacent low-level drill holes. Such as figure 2 with image 3 shown.

[0033] The specific implementation method of the middle hole: use a kilometer directional drilling rig to construct the middle hole at the appropriate position in the roadway on the return air side. The hole layers are arranged within the range of 6~25m from the coal seam roof (directly above the roof, below the old roof), and in the lateral direction withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com