Cyclic spiral cavity sodium-filled air valve with spiral blade

A spiral blade, circulating technology, applied in the field of circulating spiral cavity sodium flush valve, can solve the problems of affecting the uniformity of exhaust valve heat dissipation, reducing the overall quality of the valve, reducing the life of the exhaust valve, etc., to make up for the mechanical strength, The effect of improving circulation and reducing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

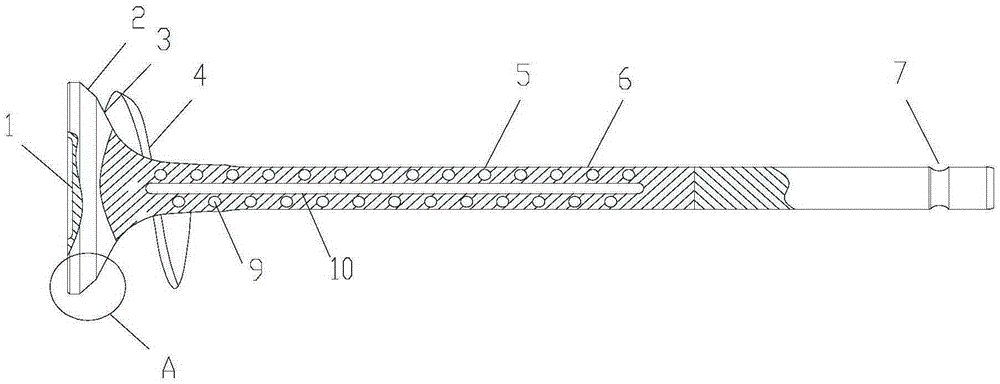

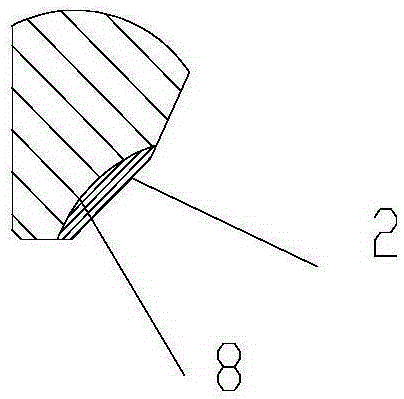

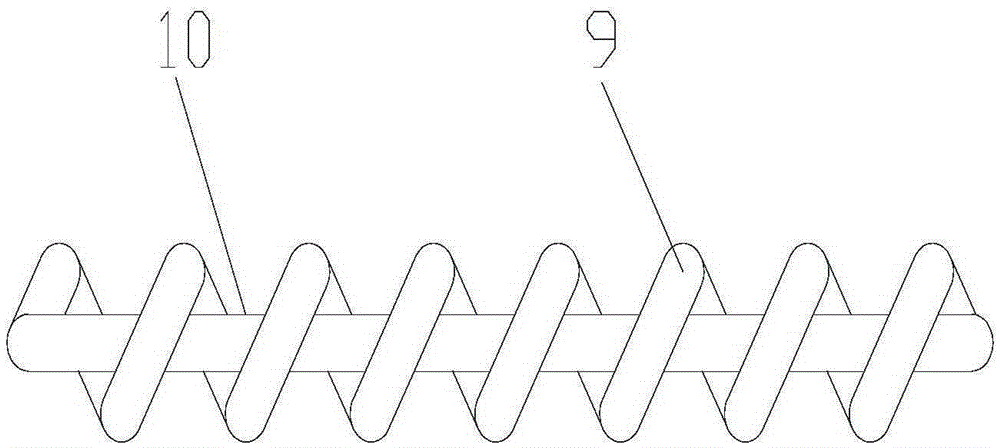

[0016] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 In the partial enlarged view of A, as shown in the figure, the circulating spiral cavity flushing sodium valve with spiral blades in this embodiment includes a valve head 3 and a valve stem, and the outer wall of the valve head 3 is provided with a To the extended spiral blade 4, a circulating spiral flow channel 9 is provided inside the valve stem, and the circulating spiral flow channel 9 includes a spiral flow channel extending axially along the valve stem and a return flow channel 10 connecting the first and last ends of the spiral flow channel, The circulating spiral flow channel 9 is flushed with sodium, the surface of the valve stem is provided with a chrome-plated layer 6, and the valve head 3 is provided with an annular groove 8 along its circumference, and the inner groove 8 is covered with a surfacing layer 2 and the surface of the surfacing layer 2 is a conical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com