Pressure release testing device

A technology for calibrating devices and pressures, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as deterioration of performance and inability to perform effective detection, and achieve the effects of simple, compact, and easy-to-use structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

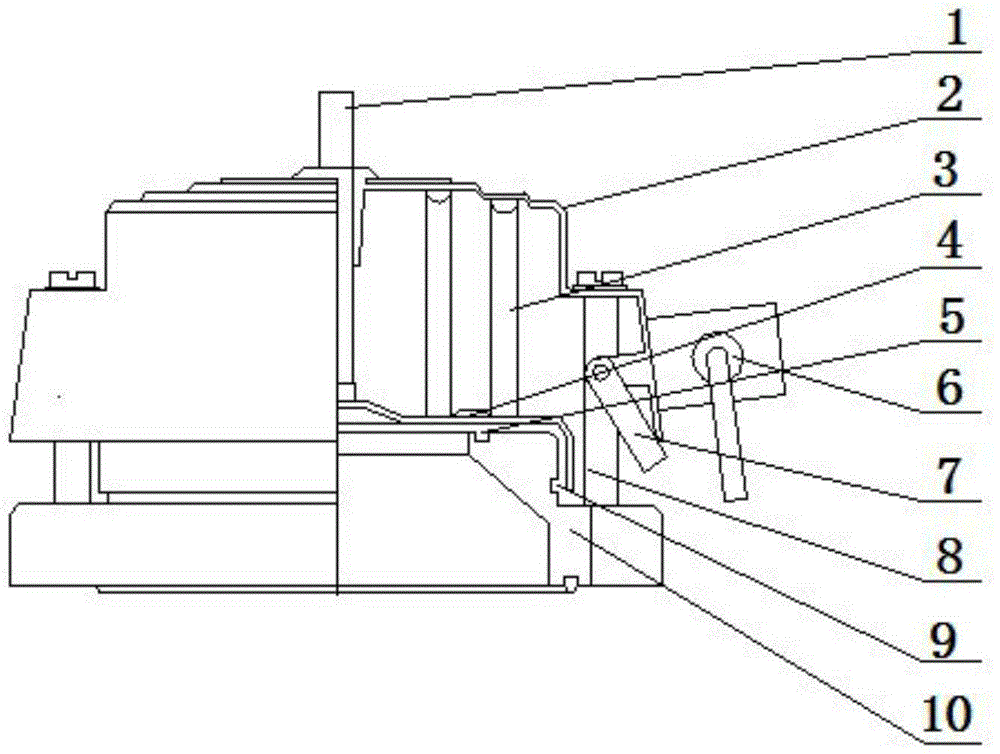

[0017] Example: such as figure 1 As shown, a pressure release inspection device of the present invention is characterized in that it includes a marker rod 1, the marker rod 1 is installed on one end of the outer cover 2 and the marker rod is embedded in the outer cover 2, and one end of the marker rod 1 is tightly connected to the diaphragm 4 A spring 3 is installed inside the outer cover 2, and both ends of the spring 3 are embedded in the inner surface of the outer cover 2; the outer cover 2 is installed on one side of the spring 3; the spring 3 is installed on one side of the diaphragm 4, and the diaphragm 4 is installed On the side of the sealing rubber ring 5; the sealing rubber ring 5 is installed on one end of the switch 6; the switch 6 is installed on the side of the positioning handle 7, and the switch 6 is arranged on the surface of the outer cover 2; the positioning handle 7 is installed on the One end of the guide post 8 and the positioning handle rod are embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com