DC source full-coverage automatic test system

A technology of automated testing and DC power supply, applied in the direction of power supply testing, etc., can solve problems that affect test accuracy and test efficiency, cumbersome test process, and fatigue of engineers, so as to improve test efficiency, reduce workload, and avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

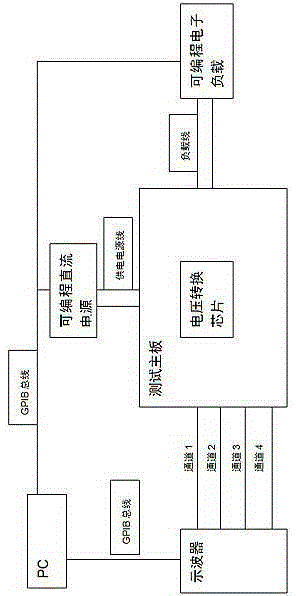

[0020] Such as figure 1 As shown, a DC power full-coverage automated test system, the test system includes a test motherboard, a programmable DC power supply, a programmable electronic load, an oscilloscope, and a PC (ie: PersonalComputer), where the programmable DC power output is connected to the test The main board supplies power for the main board; the output terminal of the voltage conversion chip of the programmable DC power supply is connected to the programmable electronic load; the four channels of the oscilloscope are connected to the signals to be captured in sequence, and channel 1 is connected to the input voltage terminal before the voltage conversion of the programmable DC power supply. Channel 2 is connected to the enable signal of the voltage conversion chip of the programmable DC power supply, channel 3 is connected to the voltage output terminal of the programmable DC power supply, and channel 4 is connected to the PowerGood signal of the programmable DC powe...

Embodiment 2

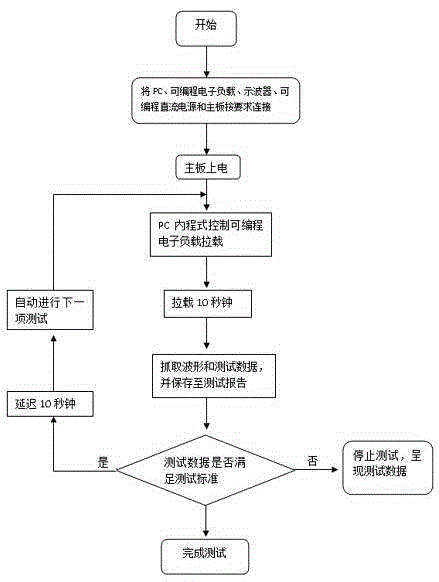

[0022] Such as figure 2 As shown, on the basis of embodiment 1, the method operation steps described in this embodiment are as follows:

[0023] 1) Prepare the main board for testing, set the DC power supply voltage conversion chip on the main board, connect the output terminal of the programmable DC power supply to the main board to supply power for the main board, connect the output terminal of the programmable DC power supply to be tested to the programmable DC electronic load, Connect the four channels of the oscilloscope to the signal to be captured in turn, channel 1 is connected to the input voltage terminal before the voltage conversion of the programmable DC power supply, channel 2 is connected to the enable signal of the programmable DC power supply voltage conversion chip, and channel 3 is connected to the programmable DC power supply The voltage output terminal of the channel 4 is connected to the PowerGood signal of the programmable DC power supply;

[0024] 2) ...

Embodiment 3

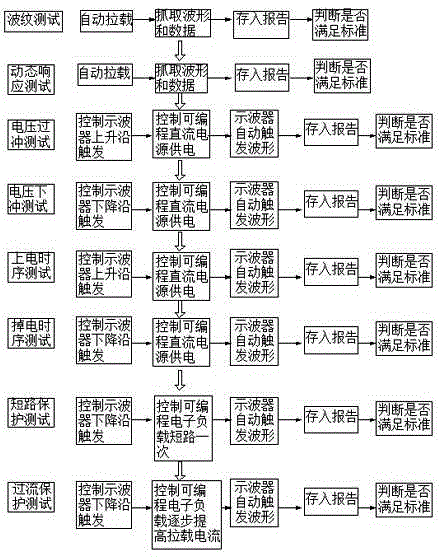

[0027] Such as image 3 As shown, on the basis of embodiment 1, the test data stored in the test report in this embodiment will be compared with the existing test standards in the report. If the test standards are met, the system will automatically perform the next test; if If the test standard is not met, the system will automatically uninstall and open the test report to display the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com