Thermal error precision conversion and model establishing method of machine tool

A model building, thermal error technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as the inability to control the accuracy of the end of the machine tool, the design lag, and the limitations of experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

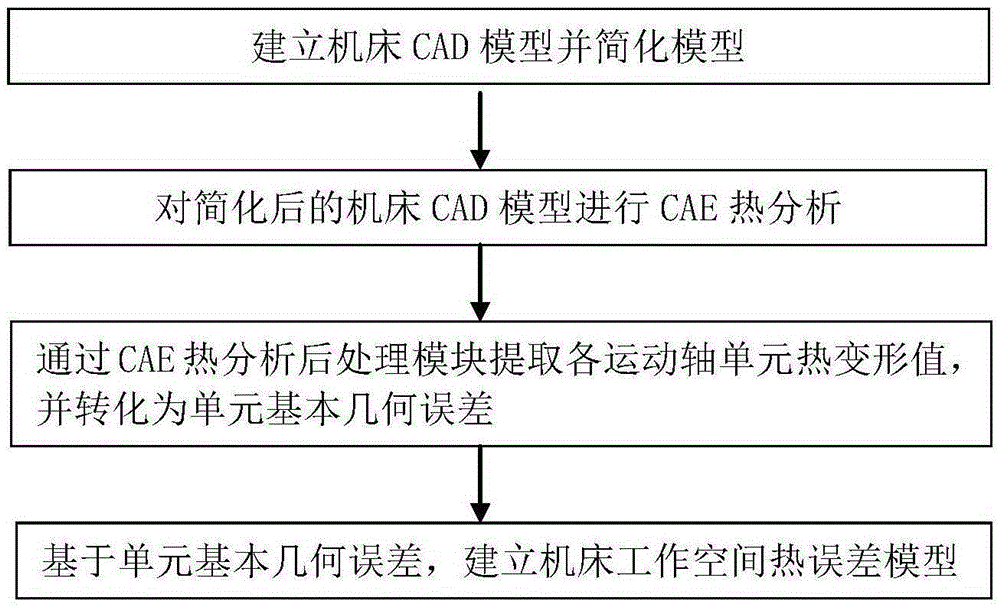

[0088] see figure 1 , a method for thermal error accuracy conversion and model establishment of a machine tool, comprising the following steps:

[0089] Step 1: Establish the CAD model of the machine tool and simplify the model;

[0090] Step 2: Perform CAE thermal analysis on the simplified CAD model of the machine tool;

[0091] Step 3: Extract the thermal deformation value of each motion axis unit through the CAE thermal analysis post-processing module, and convert it into the basic geometric error of the unit;

[0092] Step 4: Based on the basic geometric error of the unit, the thermal error model of the machine tool working space is established.

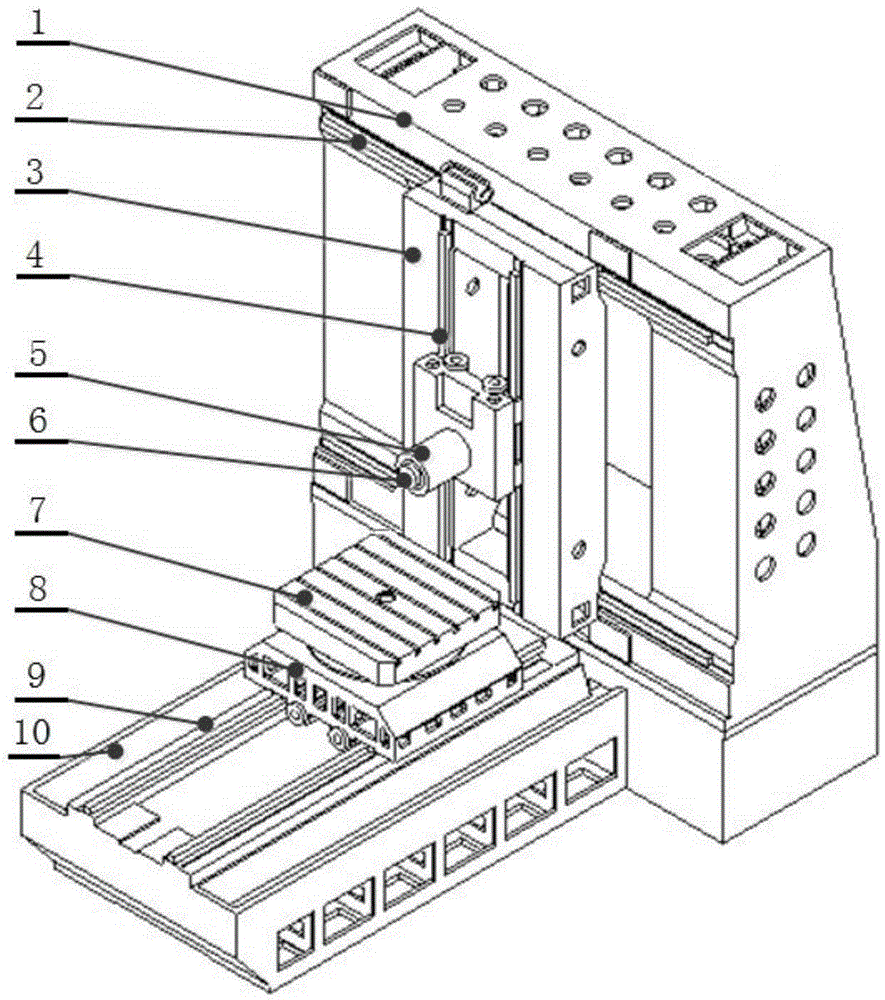

[0093] Further, in the first step, Creo software can be used to simplify the CAD model b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com