Method for holding thin wafer through temporary bonding of porous slide glass

A technology for temporary bonding and thin wafers, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., to achieve the effects of reducing usage, avoiding poor heat dissipation, and easy heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. For convenience of description, the components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments.

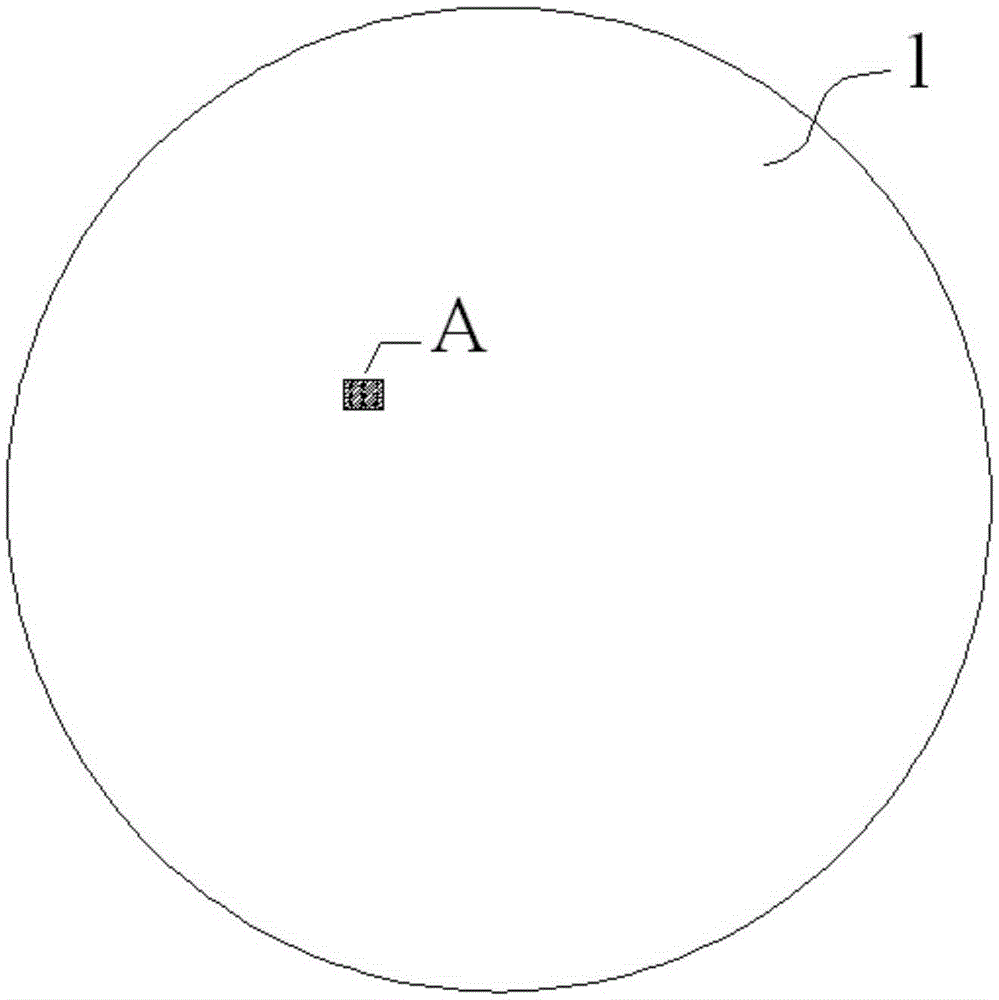

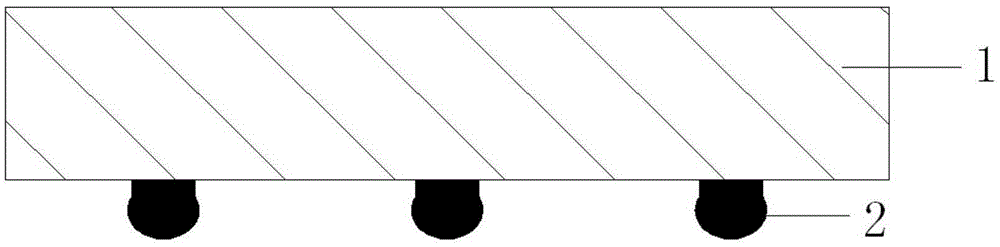

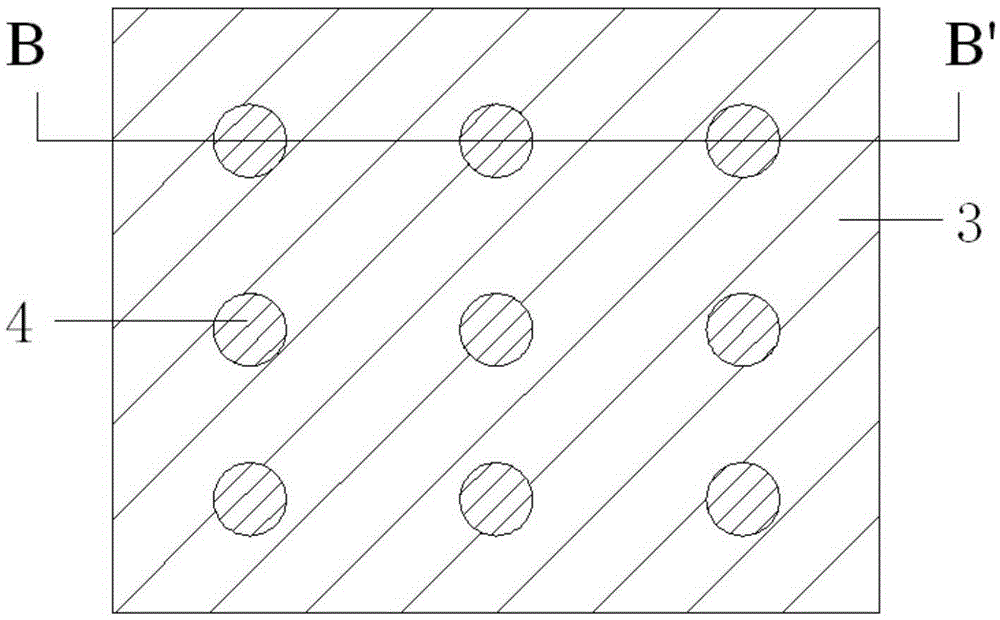

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a method for temporarily bonding and holding a thin wafer on a porous carrier, through the method of temporarily bonding glue, a wafer 1 with a number of bumps 2 on the front and a wafer 1 with a number of relief slots 4 on the surface The temporary carrier 3 is bonded together, and the higher bumps or all the bumps are inserted into the relief slots on the temporary carrier; after the back process of the wafer is completed, it is immersed in the chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com