Visible-light infrared mixed imaging detector pixel structure and manufacturing method thereof

An imaging detector and pixel structure technology, applied in the field of microelectronics, can solve the problems affecting the imaging quality, the large alignment deviation of the infrared image part and the visible light image part, etc., so as to improve the imaging quality, improve the light utilization rate and reduce the loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

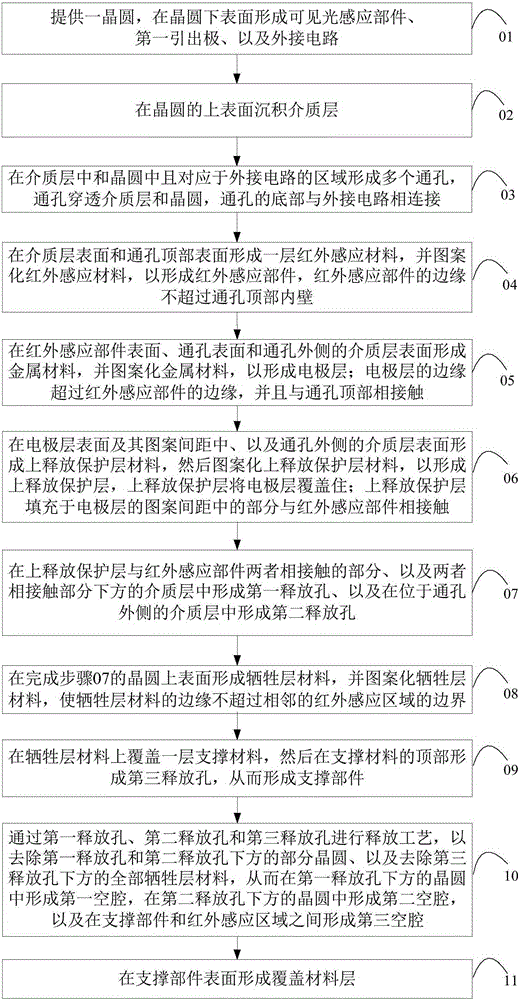

[0046] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

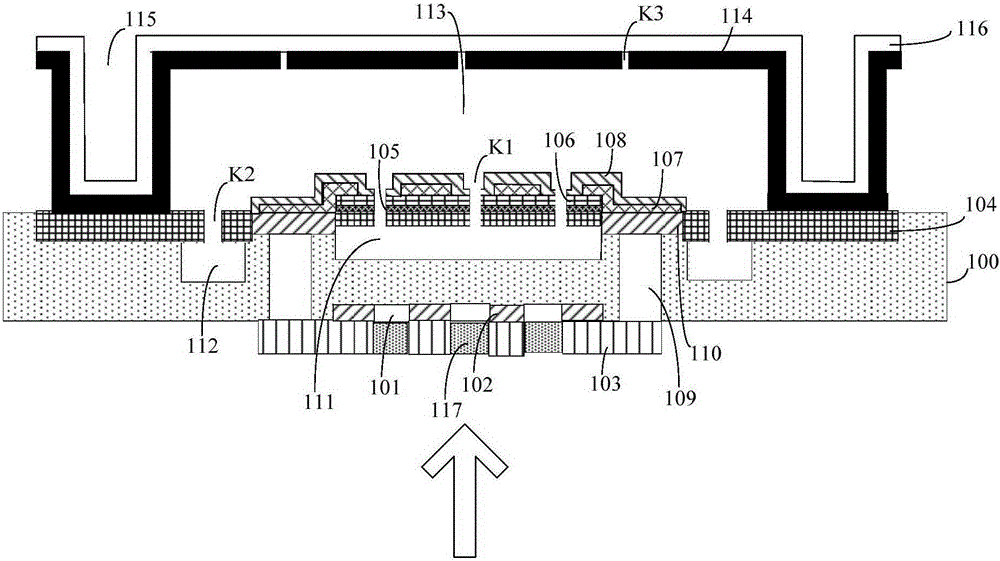

[0047] The pixel structure of the visible-infrared hybrid imaging detector of the present invention includes: a wafer used as a filter layer for filtering out visible light, near-infrared light and mid-infrared light; a visible light sensing area located on the lower surface of the wafer, which includes The visible light sensing part and the first lead-out pole that outputs the electrical signal formed by the visible light sensing part; the external circuit on the lower surface of the wafer located outside the edge of the visible light sensing area, and the infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com