Phase-locked two-mirror cavity concurrent combined carbon dioxide laser

A phase-locking, carbon dioxide technology, applied in the fields of optics, optical engineering and terahertz lasers, can solve the problems of high output mirror power density, inability to provide laser light source for terahertz lasers, and coherence that cannot meet laser rapid processing and high-precision processing. , to achieve good coherence and avoid optical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

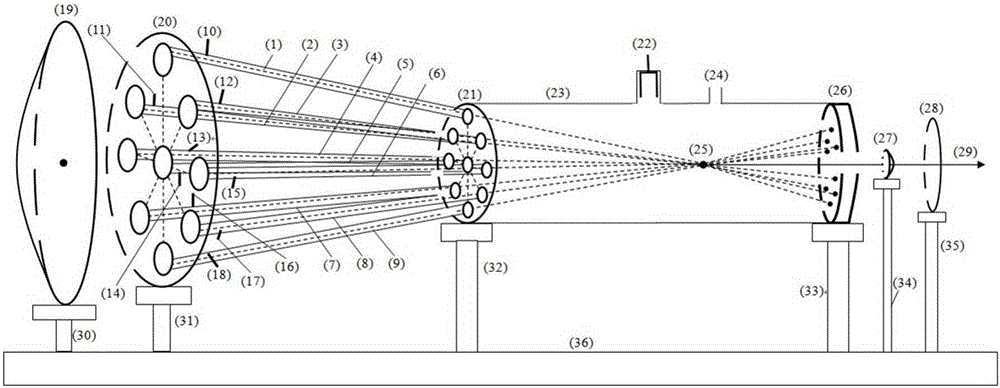

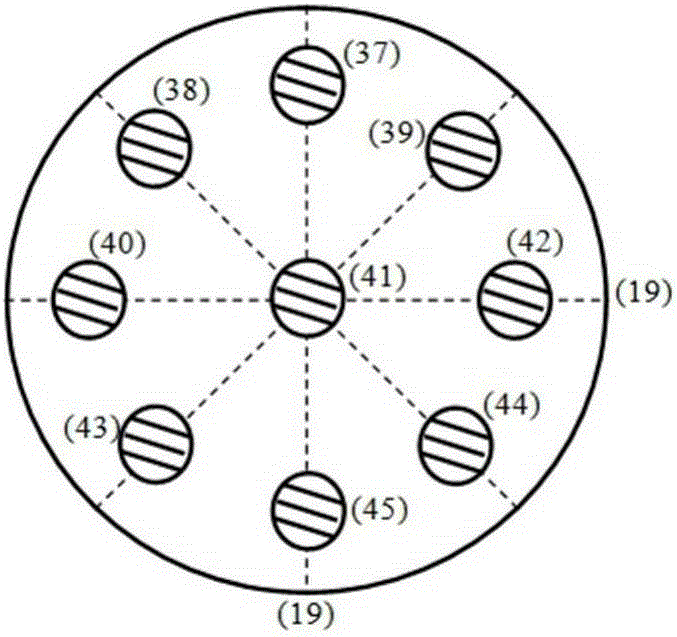

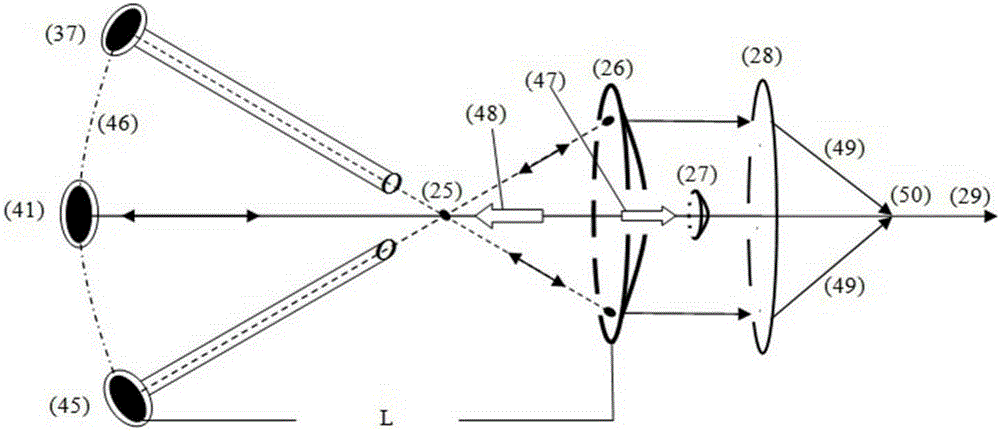

[0043] refer to figure 1 , 2, 3, take 9 first discharge tube 1, second discharge tube 2, third discharge tube 3, fourth discharge tube 4, fifth discharge tube 5, sixth discharge tube 6, seventh discharge tube 7, eighth discharge tube Discharge tube 8, the ninth discharge tube 9, the axes of each discharge tube are located on the same conical surface, and intersect at the common intersection point 25, which is the phase-locked two-mirror cavity co-point combined carbon dioxide laser, the length of each discharge tube All are 1.2m, internal diameter is 12mm, and external diameter is 14mm, and the first concave total reflection mirror 37, the second concave total reflection mirror 38, the third concave total reflection mirror 37, the second concave total reflection mirror 38, and the third concave total reflection mirror are symmetrically placed on the mirror surface of the combined mirror 19. Mirror 39, fourth concave total reflection mirror 40, fifth concave total reflection m...

Embodiment 2

[0045] refer to figure 1 , 4 , refer to figure 1 , 2 , 3, take 9 first discharge tube 1, second discharge tube 2, third discharge tube 3, fourth discharge tube 4, fifth discharge tube 5, sixth discharge tube 6, seventh discharge tube 7, eighth discharge tube Discharge tube 8, the ninth discharge tube 9, the axes of each discharge tube are located on the same conical surface, and intersect at the common intersection point 25, which is the phase-locked two-mirror cavity co-point combined carbon dioxide laser, the length of each discharge tube Both are 1.2m, the inner diameter is 12mm, the outer diameter is 14mm, the radius of curvature of the spherical mirror 51 is 1.3m, and the distance to the first support 20 of the discharge tube is 10cm. The output mirror 26 is a curved convex mirror, placed on the symmetry axis 29 of the laser, and located at 20cm to the right of the common intersection point 25, the radius of curvature of the first reflecting surface is 20cm, the radius...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com