Radial-adjusting permanent magnetism speed adjusting device

A technology of permanent magnet speed regulation and magnetic steel, which is applied in the direction of electromechanical devices, electromechanical transmission devices, electrical components, etc., can solve the problems of large equipment vibration, difficult installation, large axial size, etc., and achieve reduced bearing heating and reasonable structural design , the effect of small axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that the embodiments in the invention and the features in the embodiments can be combined with each other if there is no conflict.

[0028] The specific embodiments created by the present invention will be described in detail below with reference to the accompanying drawings.

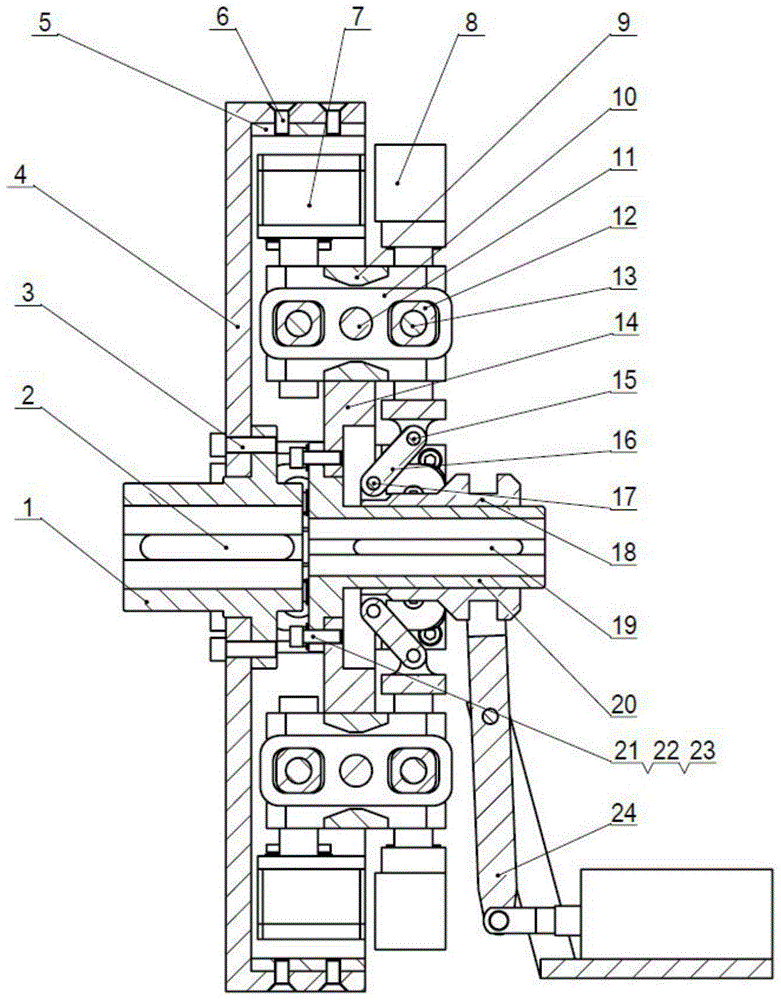

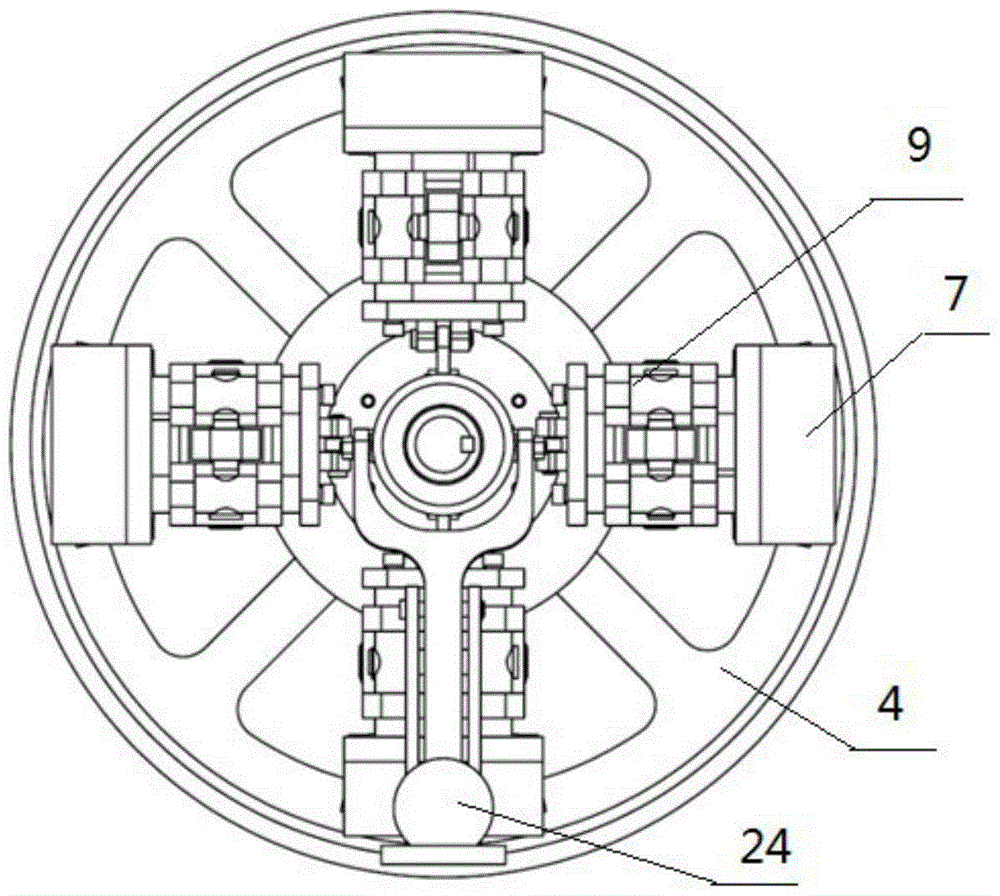

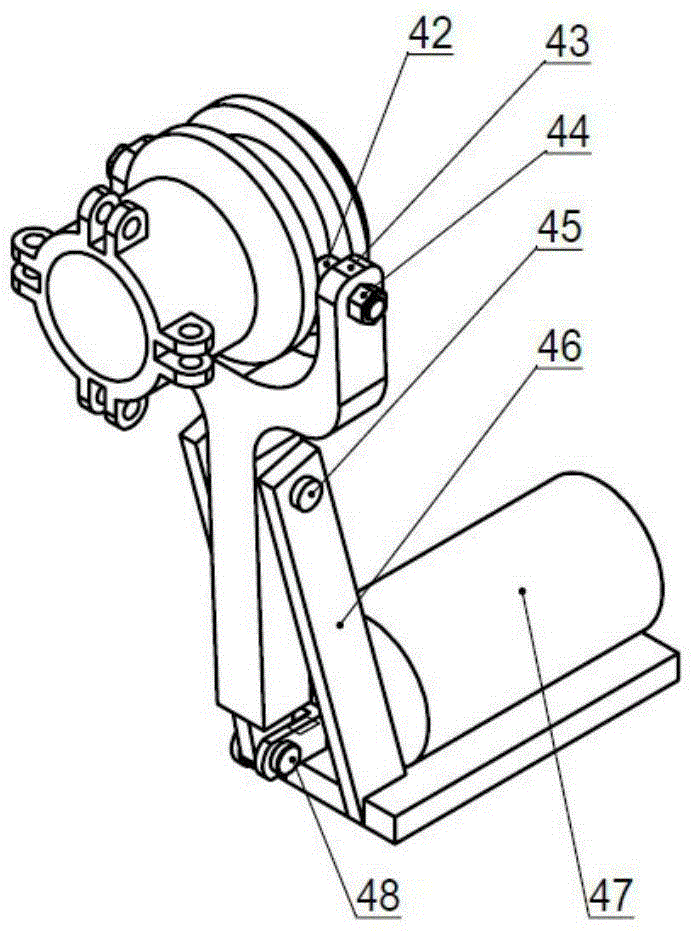

[0029] Such as Figure 1 to Figure 8 The shown a radially adjustable permanent magnet speed regulating device includes a first coupling 1 connected with a motor shaft and a second coupling 20 connected with a load shaft; the first coupling 1 is installed There is a conductor rotor 4 with a conductor ring 5 installed on the conductor rotor 4; a movable sleeve 18 is sleeved on the second coupling 20, and the movable sleeve 18 is driven by a driving mechanism 24 along the second coupling 20 The moving sleeve 18 is connected to a gap adjustment mechanism through a connecting rod 16; the gap adjustment mechanism is provided with a magnetic steel assembly 7 corresponding to the conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com