Method for the controlled operation of regeneratively heated industrial furnace, control unit and industrial furnace

An industrial boiler and heat storage technology, which is applied in the direction of furnace control devices, combustion control, lighting and heating equipment, etc., can solve the problems of unavailable, uncontrollable thermal value fluctuations, temperature fluctuations, etc., and achieve reliable determination and reliable oxygen consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

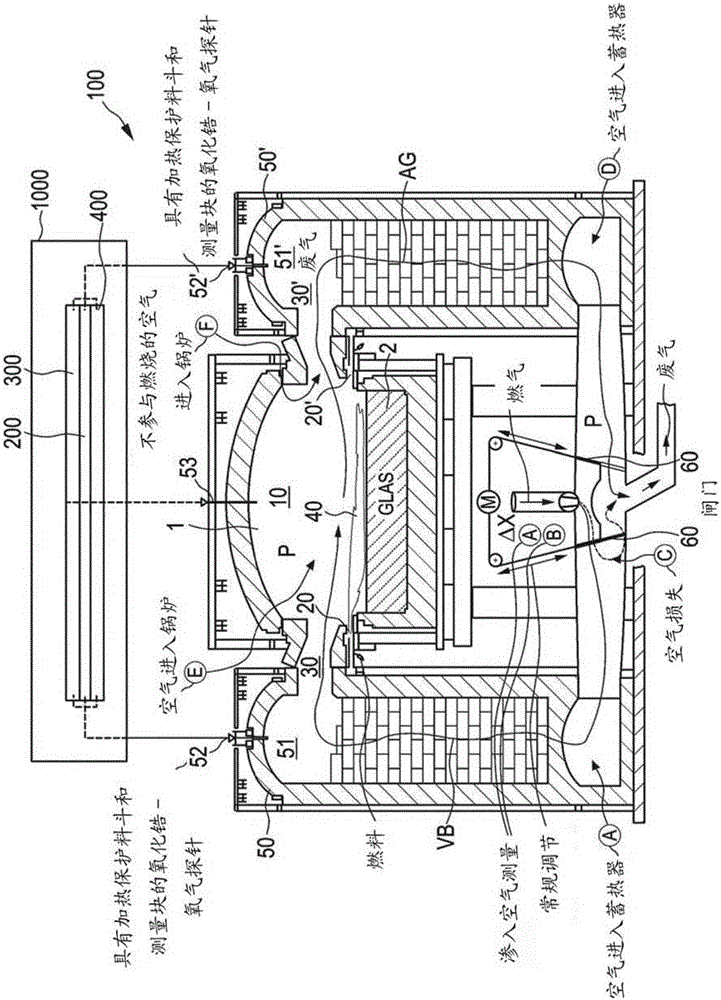

[0048] figure 1 A simplified diagram shows a regenerative heating industrial boiler 100 with a furnace chamber 10 , the upper furnace chamber 1 being controlled as the controlled object, wherein the lower furnace chamber 2 has a glass melting tank (not shown in detail). The glass contained in the glass melting bath is heated by the furnace chamber 10 above the melting temperature, and is melted and properly processed for the manufacture of glass bottles and the like. The industrial boiler 100 is heated here, the upper furnace 1 is injected with fuel here in the form of gas via a plurality of side-mounted fuel injectors 20 . The fuel injector 20 here represents the left injector 20 . The other fuel injector 20' represents here the right injector 20'. For reasons of simplification, the same reference numbers are used below for identical or similar components or components with the same or similar function. For example, a number of six syringes 20 , 20 ′ can be arranged on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap