A multi-layer disc centrifugal and gravity film-forming microwave evaporation device

An evaporating device and disc-type technology, which is applied in the field of multi-layer disc centrifugal and gravity film-forming microwave evaporating devices, can solve the problem of insufficient evaporation of volatile components, which affects the improvement of heat exchange efficiency and increases the load of gas-liquid separation And other problems, to achieve the effect of low temperature evaporation, improve heating efficiency, and improve evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

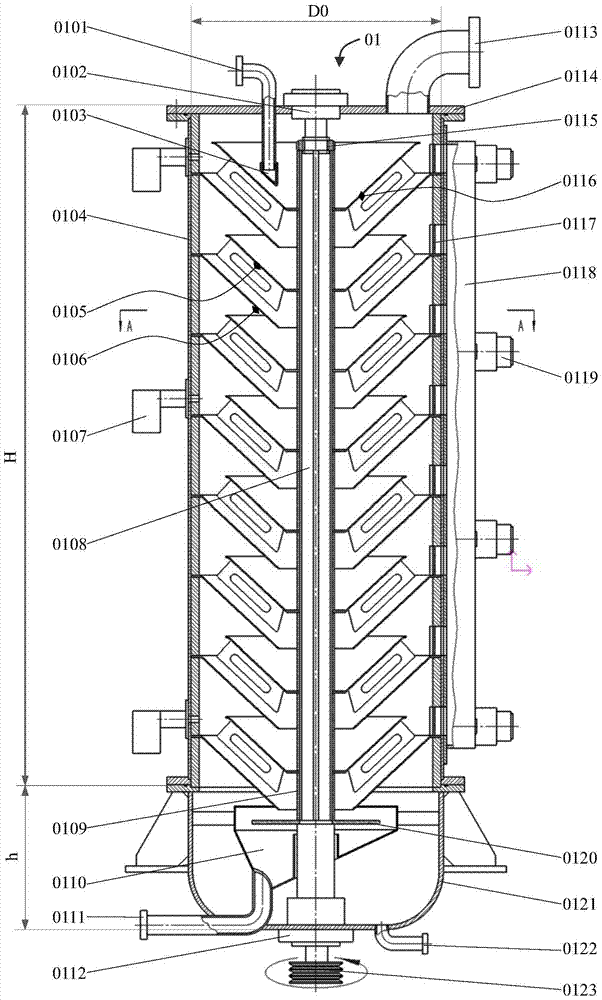

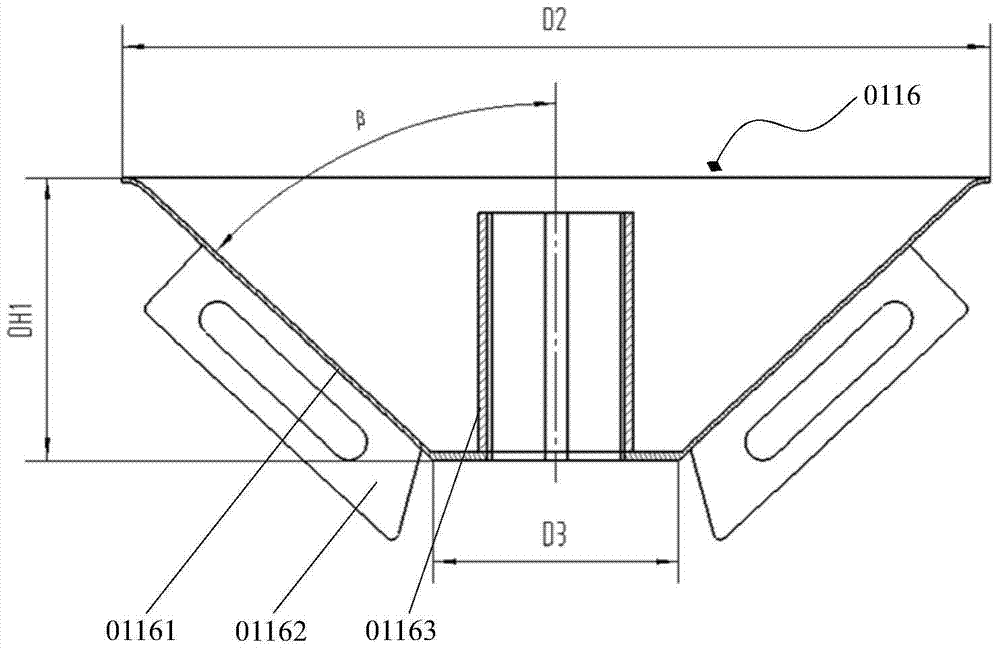

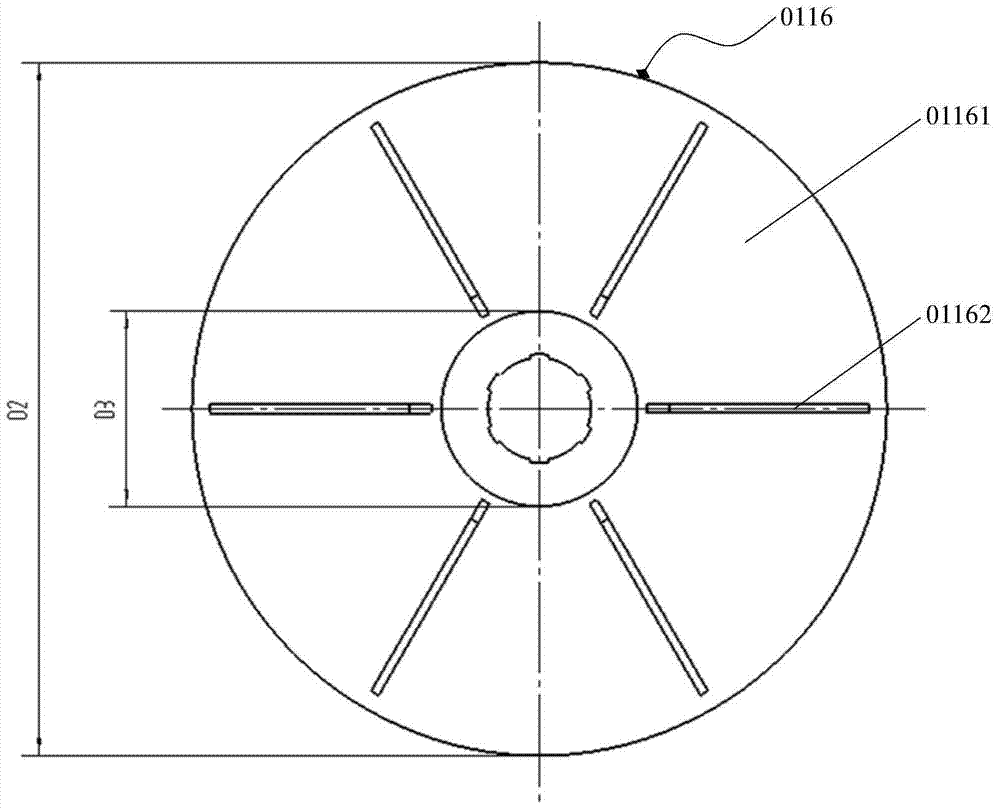

[0068] Such as figure 1 As shown, a multi-layer disc centrifugal and gravity film-forming microwave evaporation device 01 provided by the present invention has a structure including: feed liquid feeding nozzle 0101, upper bearing assembly 0102, feed liquid nozzle 0103, cylinder body 0104, rotary cone Surface disc assembly 0105, fixed cone disc assembly 0106, infrared thermometer 0107, central shaft 0108, lower positioning bushing 0109, concentrate collecting bucket 0110, concentrate discharge connection 0111, lower bearing assembly 0112, evaporated gas Export connection tube 0113, upper cover of cylinder body 0114, tightening round nut 0115, top rotary conical disc assembly 0116, microwave feeder transparent plate 0117,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com