Preparing method for Pt-Co flower-type nano-catalyst

A nanocatalyst, pt-co technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of limited known reserves, easy poisoning of catalysts, and preparation methods to be improved, and achieve broad application Prospects, the effect of the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

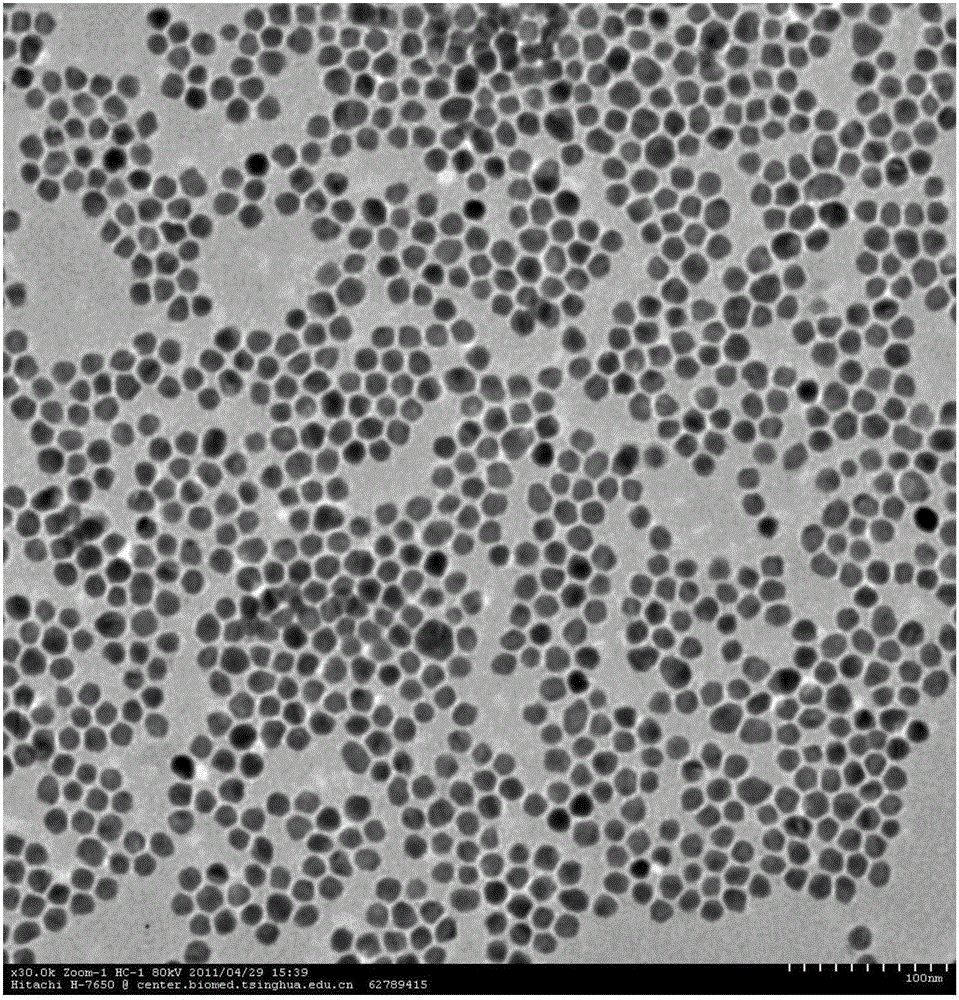

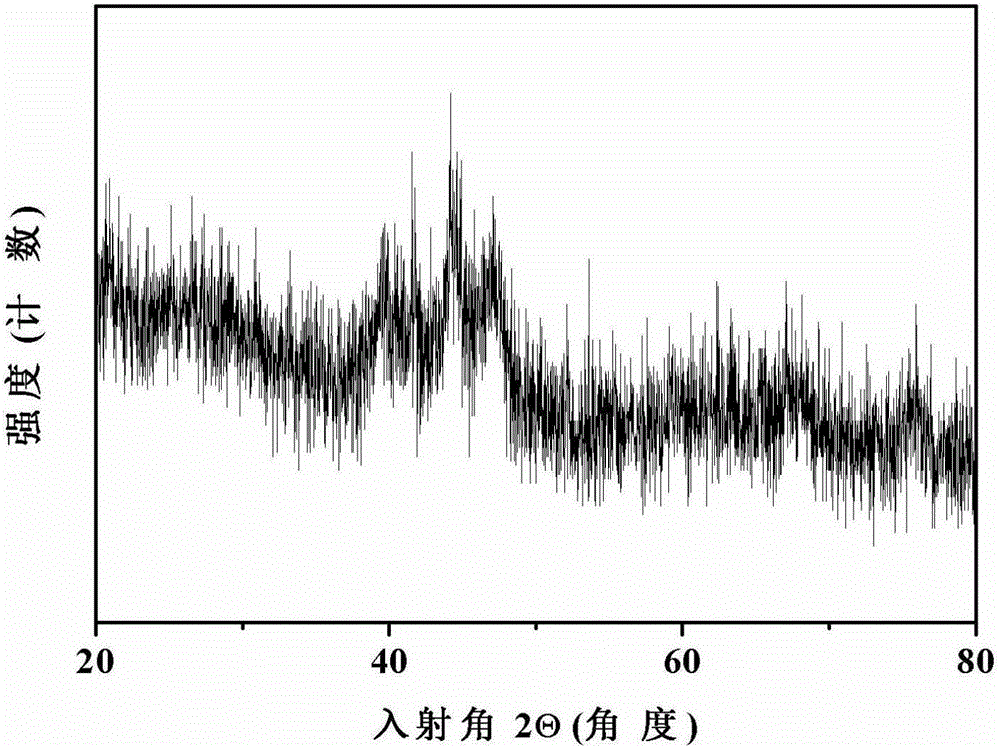

[0033] 1) Add 10ml toluene and 0.5ml oleylamine to the reactor, then add 0.01g cobalt acetylacetonate and 0.03g tributylammonia borane complex; after stirring for 20 minutes, put the reactor into an oven; °C for 10 hours. After the reaction, the obtained Co nanoparticles were washed with ethanol three times and placed in ethanol for later use.

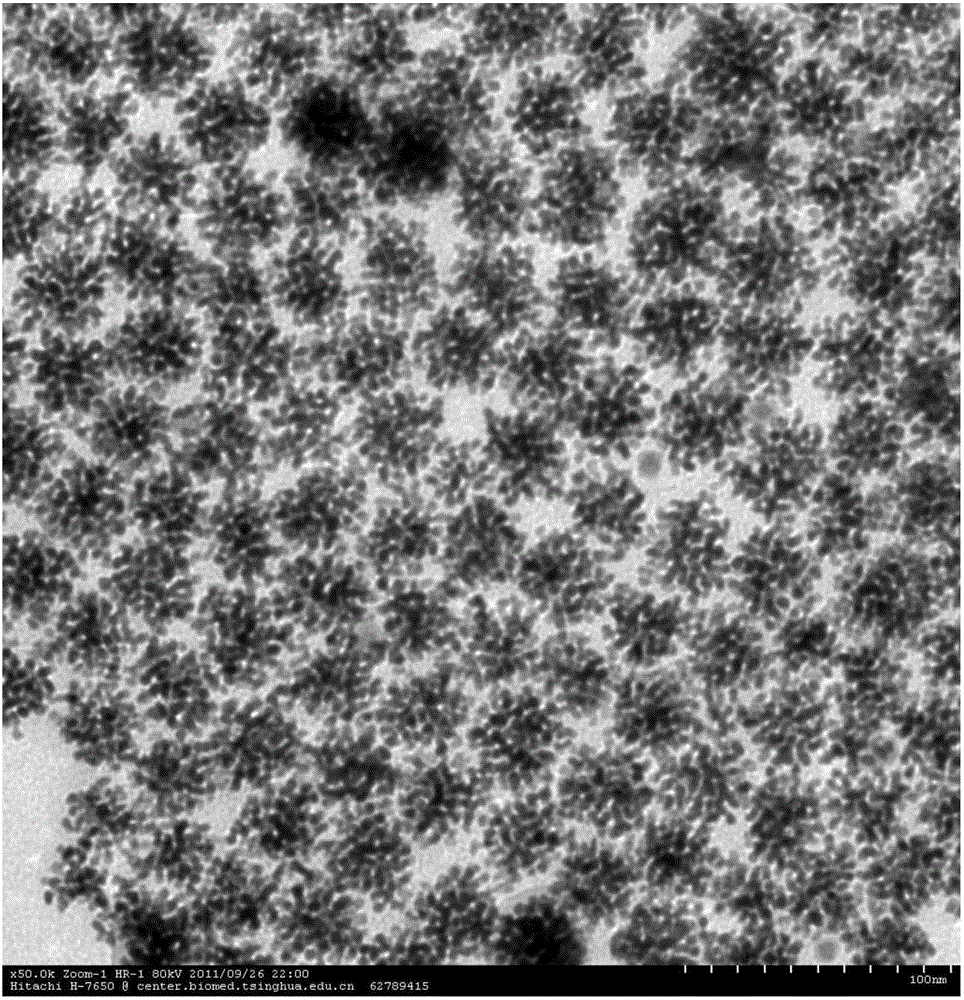

[0034] 2) Dissolve 5 g of octadecylamine at 60° C., and then add 0.02 g of Co nanoparticles and 0.015 g of tributylammonia borane complex. After stirring for about 1 hour, 0.01 g of platinum acetylacetonate was added. The temperature was raised to 160°C, and the heating was stopped after 2 hours of reaction. The product was washed 3 times with ethanol and stored in ethanol.

Embodiment 2

[0036] Other steps are the same as in Example 1, except that the platinum acetylacetonate in step 2 is changed to 0.005g.

Embodiment 3

[0038] Other steps are the same as in Example 1, except that the platinum acetylacetonate in step 2 is changed to 0.015g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com