A movable working cylinder nylon sintering forming machine

A technology for working cylinders and forming machines, applied in manufacturing, additive processing, solid material additive processing, etc., can solve problems such as reducing equipment work efficiency, save cooling and preheating time, improve efficiency, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

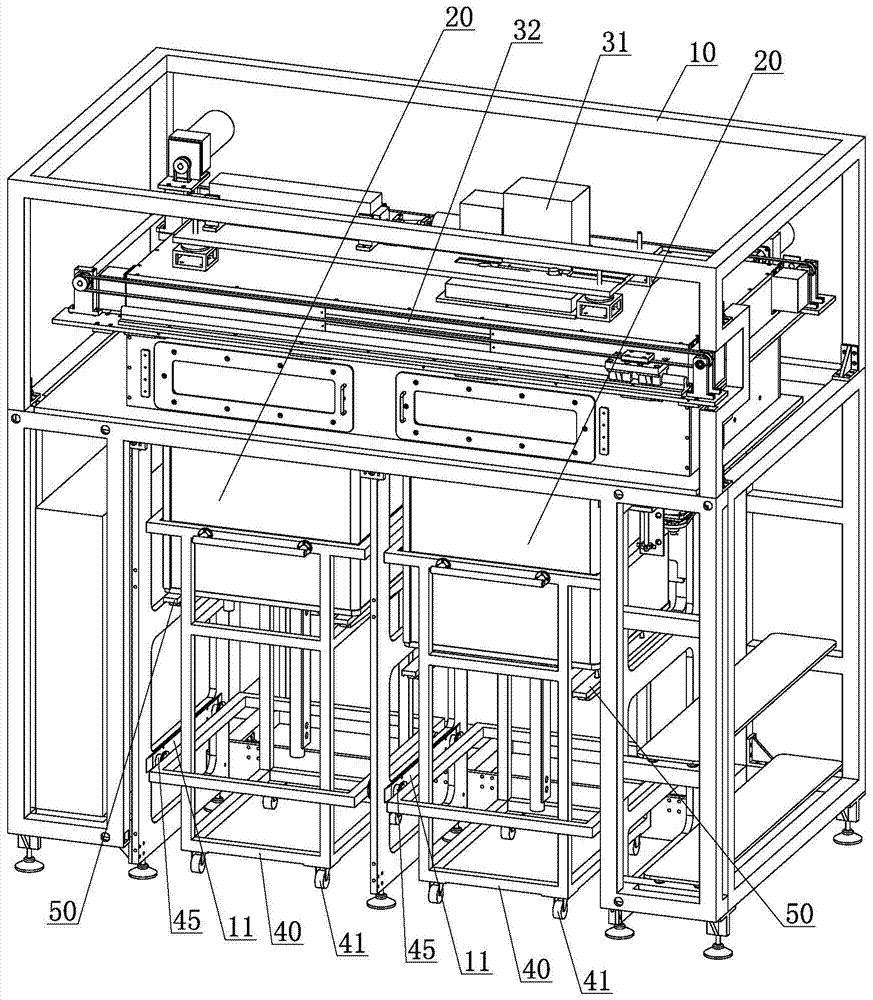

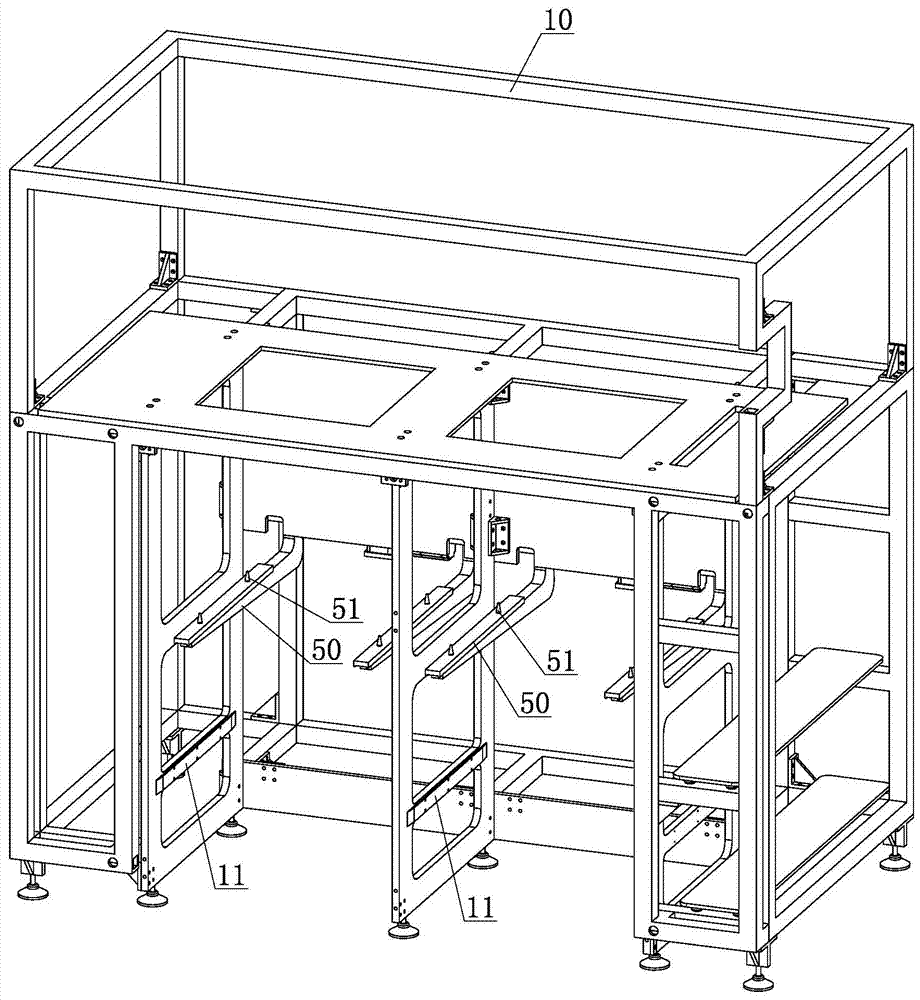

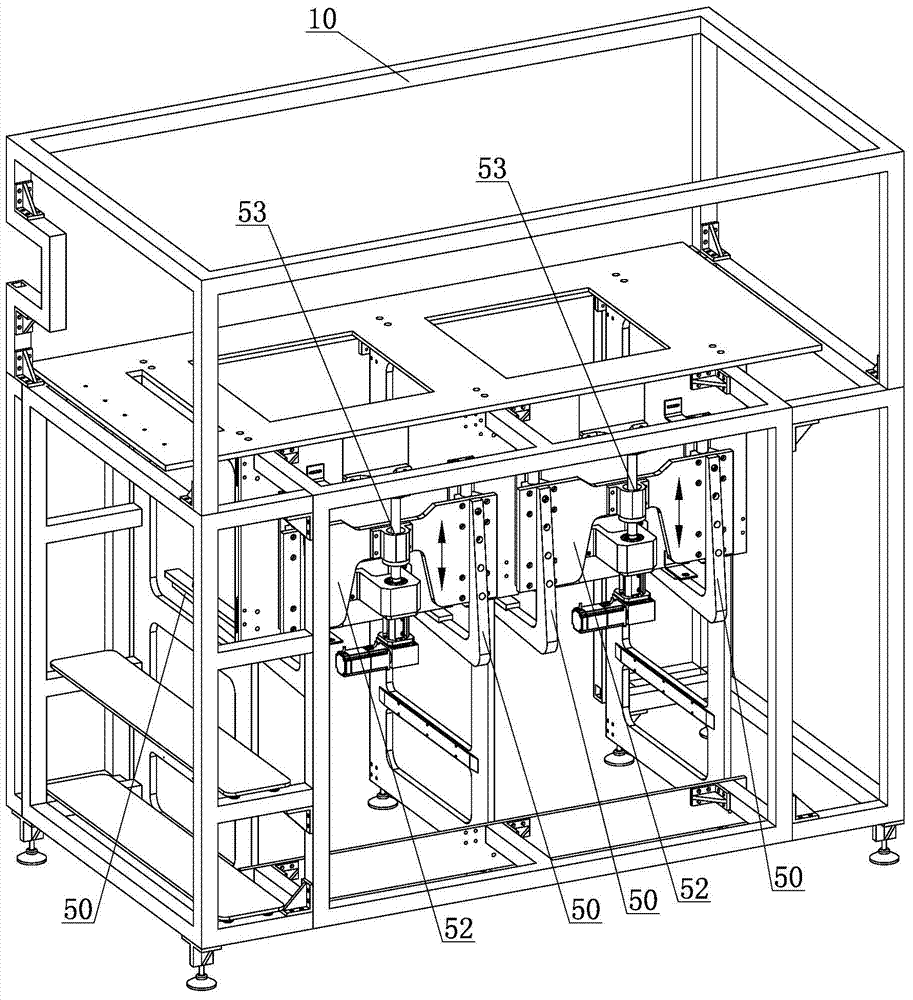

[0035] like Figure 1 to Figure 5 , a movable working cylinder nylon sintering molding machine, including a forming machine frame 10, two working cylinders 20 arranged side by side, a laser vibrating mirror scanning device 31 and a powder spreading device 32 arranged above the working cylinders.

[0036] A working cylinder is a movable working cylinder that can be moved into and out of a working position. The working position of the working cylinder is as figure 1 Cylinder position on the left.

[0037] In order to enable the cylinders to move into and out of the working position, each cylinder is placed on a cylinder moving frame 40 . The working cylinder moving frame is a frame structure, and the bottom surface of the working cylinder moving frame is provided with a walking roller 41; Composed of beams, the width d on both sides of the working cylinder bracket is smaller than the width D of the working cylinder. The working cylinder moving frame is provided with a workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com