Material handling device

A technology for handling devices and materials, applied in the field of robots, which can solve problems such as increased work intensity, staff injuries, and large limitations, and achieve the effects of improved work efficiency, low production costs, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose and features of the present invention more obvious and easy to understand, the following will further describe the specific embodiments of the present invention in conjunction with the accompanying drawings. However, the present invention can be realized in different forms, and should not be considered as being limited to the described embodiments .

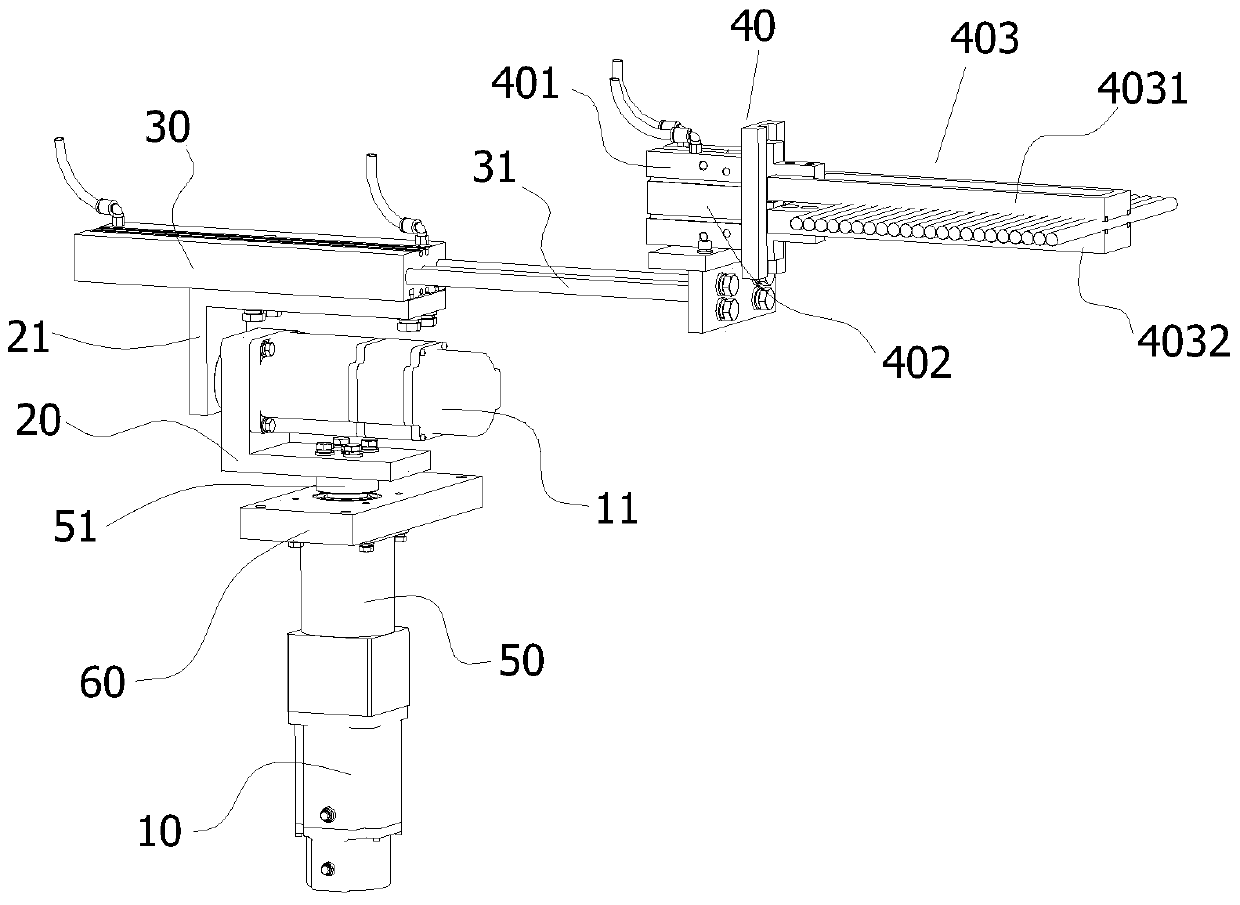

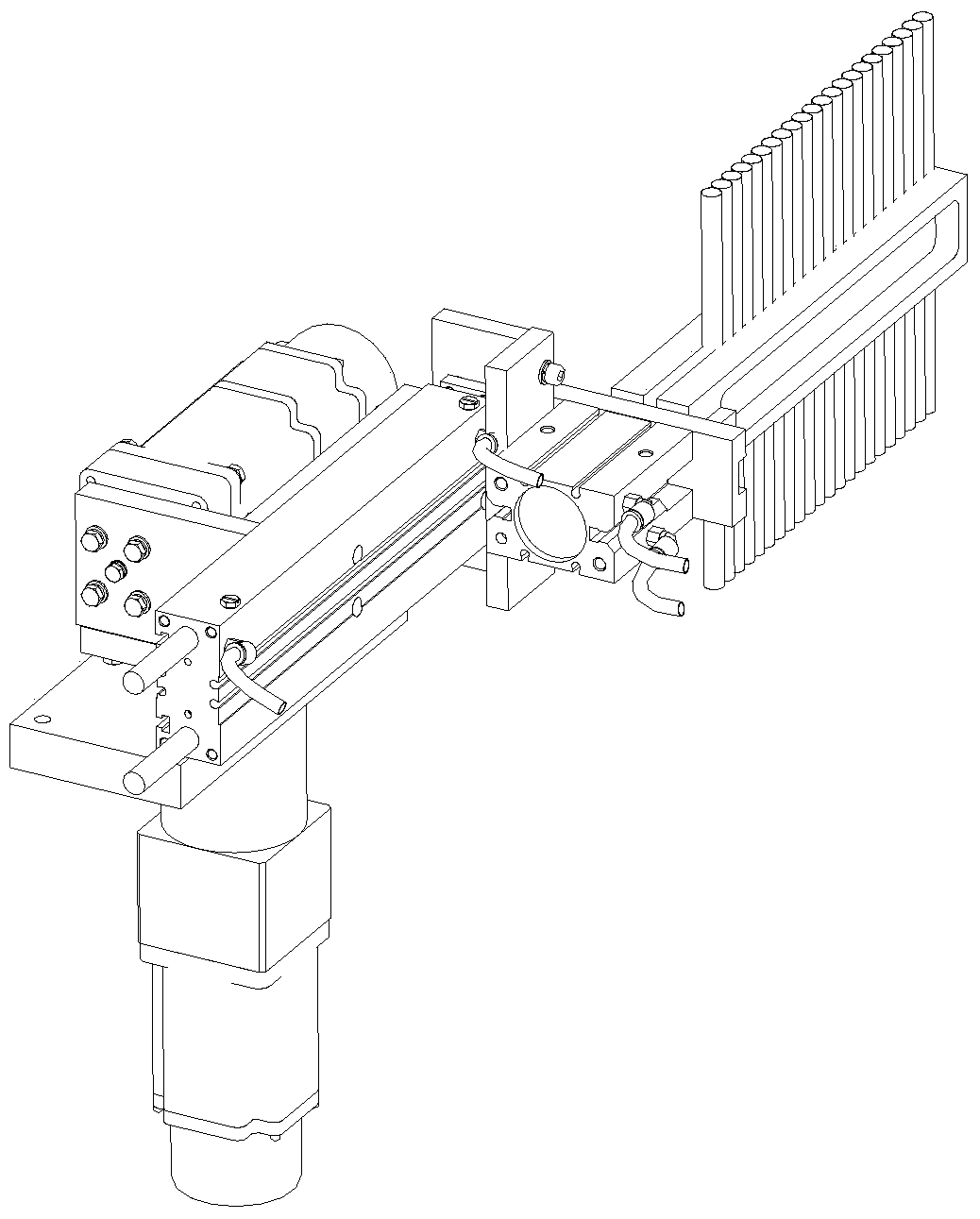

[0024] Such as figure 1 and figure 2 Shown is a perspective view of a preferred embodiment of the material handling device of the present invention. In this embodiment, the first drive unit is the servo motor a10, and the second drive unit is the servo motor b11. In the figure, the rotating shaft flange 51 is movably installed on the support plate 60 through bearings, and is connected with the reducer 50 through a key to realize synchronous rotational movement. The speed reducer 50 is fixedly connected to the support plate 60 by bolts, and the support plate 60 is fixed on the external frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com