A small flue of regenerator with variable section

A technology of small flue and regenerator, which is applied in the coking oven bricklaying operation, etc., can solve the problems of poor working environment for workers, coking at the burner head, and heavy adjustment workload, so as to reduce the smoke emission at the burner head, increase the Effect of gas supply, reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

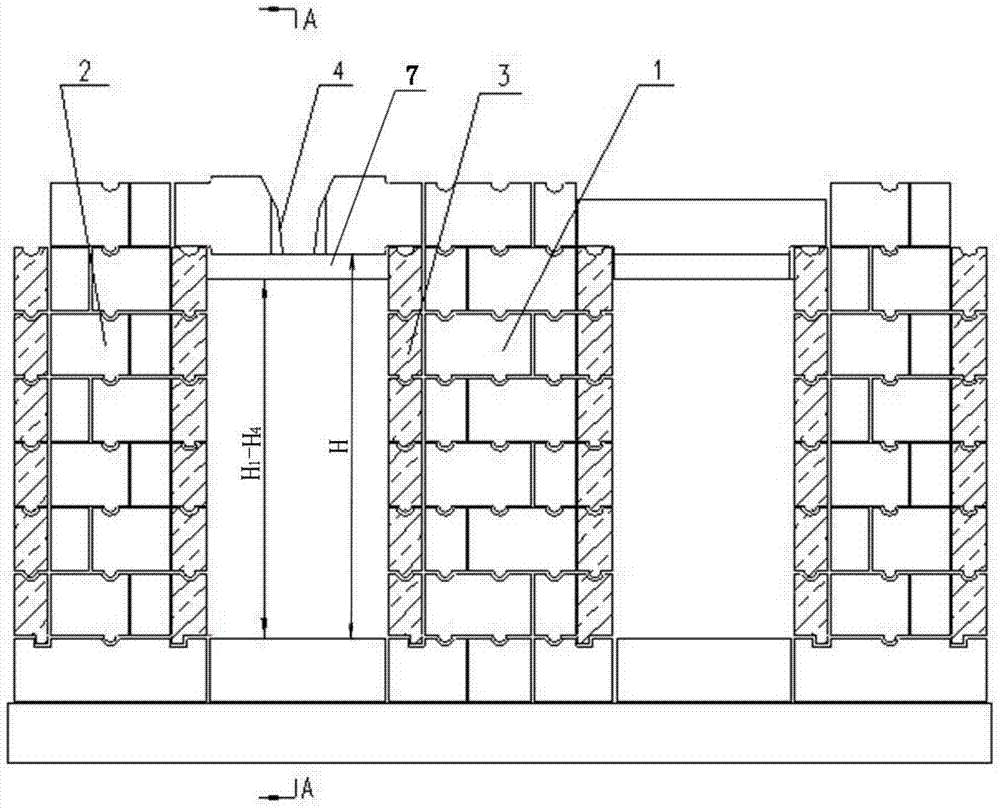

[0031] Such as Figure 1-Figure 2 Shown is a kind of specific structural form of the present invention. In this embodiment, the grate partition wall brick 7 protrudes from the lower surface of the grate brick layer, and the height of the protrusion gradually decreases along the direction from the furnace head to the central partition wall 5; the surface of the side wall lining brick layer 3 is even, and the bottom of the flue Lining brick 9 is plane.

[0032] In this embodiment, the multi-channel grate partition wall bricks 7 in the small flue are all lower than the lower surface of the grate brick layer, which changes the height H of the small flue at the partition wall, as figure 2 As shown, the cross-sectional heights of the small flues at 7 places of the 4 grate partition wall bricks are H1-H4 respectively. The height of the section of the local flow channel in the small flue is changed, so as to achieve the purpose of improving the uniformity of the air flow in the hea...

Embodiment 2

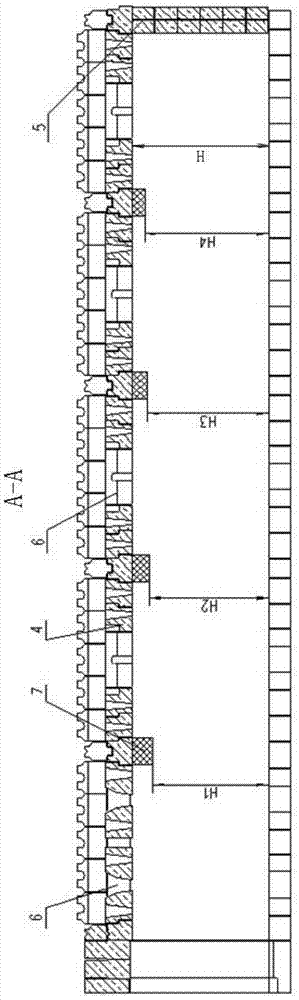

[0034] Such as Figure 3-Figure 4 Shown is a kind of specific structural form of the present invention. In this embodiment, the partial side wall lining brick 8 protrudes from the surface of the side wall lining brick layer 3, the grate partition wall brick 7 is flush with the lower surface of the grate brick layer, and the flue bottom lining brick 9 is a plane.

[0035] The side wall lining brick of the small flue and the corresponding part of the grate brick partition wall brick 7 protrude from the surface of the side wall lining brick layer 3 (one side or both sides), such as image 3 As shown, the width of the small flue at the protruding part is B1, thereby changing the width B of the small flue at other parts, and the width of the cross-section of the flow channel in the small flue is changed, so that the airflow cross-sectional area of the small flue can be changed locally The purpose of improving the uniformity of the airflow in the heat storage chamber.

Embodiment 3

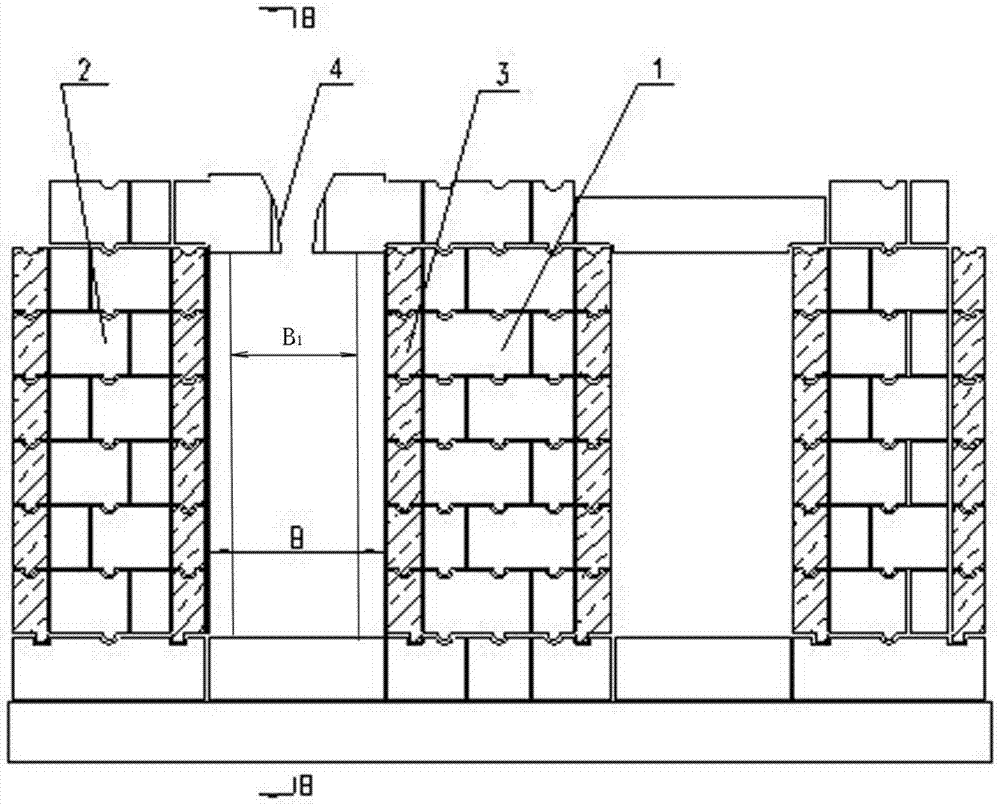

[0037] Such as Figure 5-Figure 6 Shown is a kind of specific structural form of the present invention. In this embodiment, the lining brick 9 at the bottom of the flue is inclined, and the height gradually increases along the direction from the furnace head to the central partition wall 5; the grate partition wall brick 7 is flush with the lower surface of the grate brick layer, and the side wall lining brick layer 3 The surface is even.

[0038] The thickness of the lining brick 9 at the bottom of the small flue increases gradually from the burner head to the central partition wall 5, that is, the height H of the small flue is a variable, and the section of the air flue gradually decreases, changing the width of the cross section of the flow passage in the small flue, thereby achieving The aim is to improve the uniformity of the airflow in the heat storage chamber by changing the local airflow cross-sectional area of the small flue.

[0039] In the above three embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com