Anti-scaling agent for metal equipment

A descaling agent and equipment technology, applied in the field of descaling agents for metal equipment, can solve problems such as poor effect, and achieve the effect of easy promotion, low raw material cost, and excellent descaling effect

Inactive Publication Date: 2016-01-20

NANJING JINGYUN SHIP FITTINGS

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is to provide a descaling agent for metal equipment to solve the problem of poor effect in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0015] Materials and parts: 15 parts betaine, 7 parts benzotriazole, 4 parts fatty alcohol polyoxyethylene ether, 8 parts sodium xylene sulfonate, 14 parts polyvinyl alcohol, 10 parts aluminum silicate fiber, ethanol 15 parts and 10 parts water.

[0016] Preparation method: It is obtained after mixing the corresponding raw materials.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

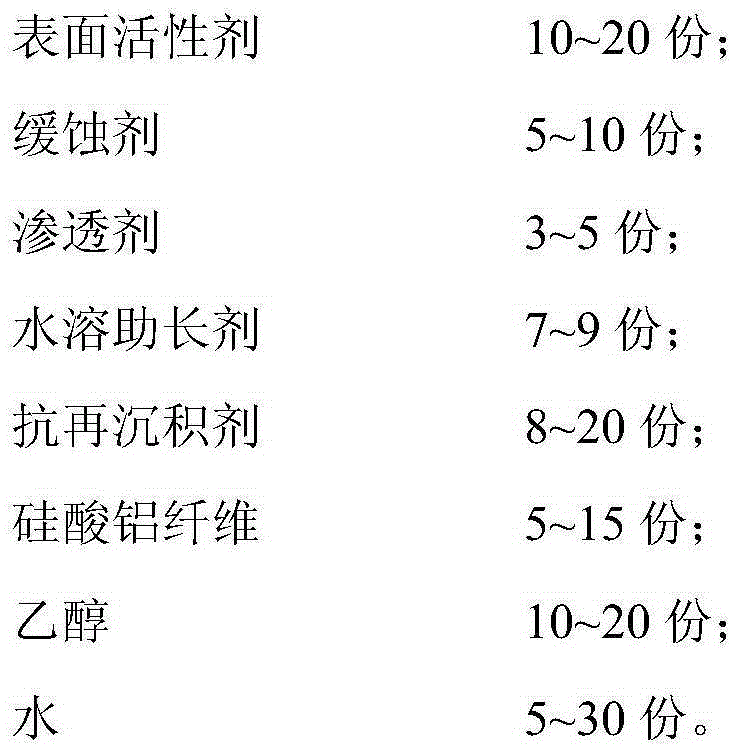

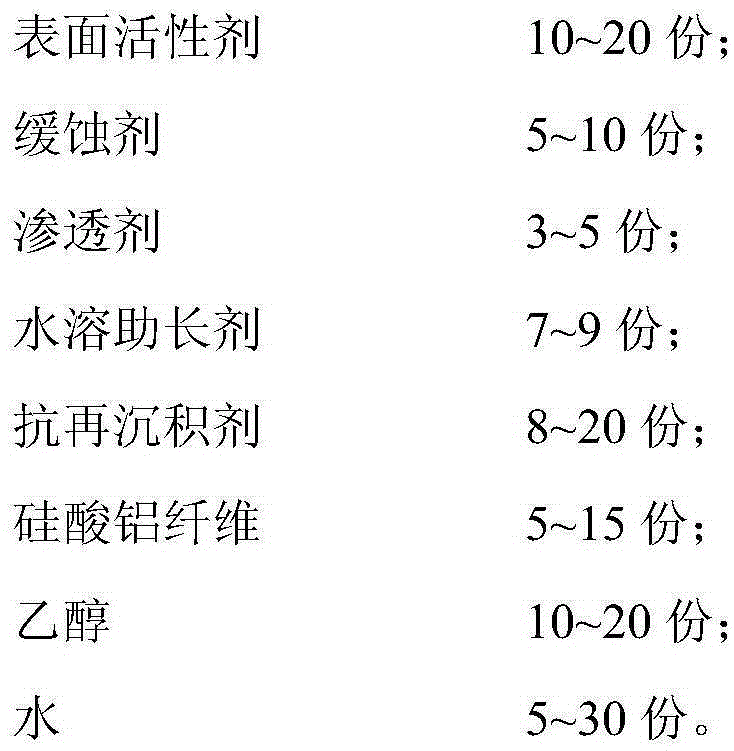

The invention discloses an anti-scaling agent for metal equipment. The anti-scaling agent for the metal equipment comprises, by weight, 10-20 parts of surface active agents, 5-10 parts of corrosion inhibitors, 3-5 parts of penetrating agents, 7-9 parts of hydrotropic agents, 8-20 parts of anti-redeposition agents, 5-15 parts of aluminum silicate fibers, 10-20 parts of ethyl alcohol and 5-30 parts of water. Compared with the prior art, the anti-scaling effect is excellent, raw materials are low in cost and popularization is easy.

Description

Technical field [0001] The invention belongs to the field of chemical engineering, and specifically relates to a descaling agent for metal equipment. Background technique [0002] Descaling agent is a chemical agent that removes scales, dirt and other scale stains, and is generally compounded by multiple components. Industrial descaling agents are mainly used to remove dirt in heat exchange equipment, boilers, etc., and household descaling agents are mainly used to remove dirt in drinking fountains. However, large and medium-sized machinery and equipment will also produce dirt after being used for a period of time. These dirt will hinder the normal operation of machinery and equipment, reduce efficiency and also bring certain safety hazards. Therefore, an efficient descaling agent for metal equipment is urgently needed by the society. Summary of the invention [0003] The technical problem to be solved by the present invention is to provide a scale remover for metal equipment to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23G5/036

Inventor 俞建福王坤甘小花

Owner NANJING JINGYUN SHIP FITTINGS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com