Method for Removing Oxide Skin on the Surface of Titanium/Titanium Alloy Strip

A titanium alloy plate and surface oxidation technology, which is applied in the field of titanium alloy surface oxide scale removal, can solve the problems of cumbersome scale removal process, high chemical activity of the base material, easy ignition and explosion of dust, etc., achieving excellent results and smooth removal process Short and stable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

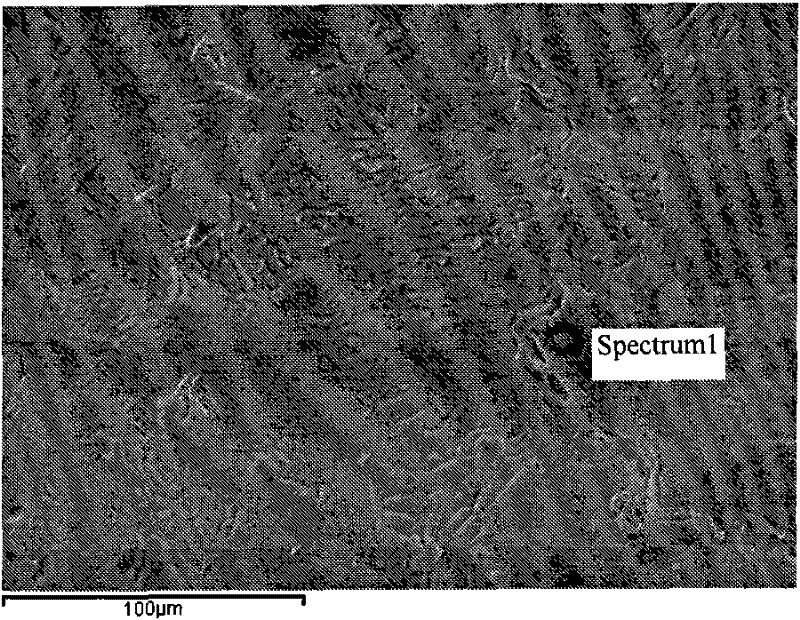

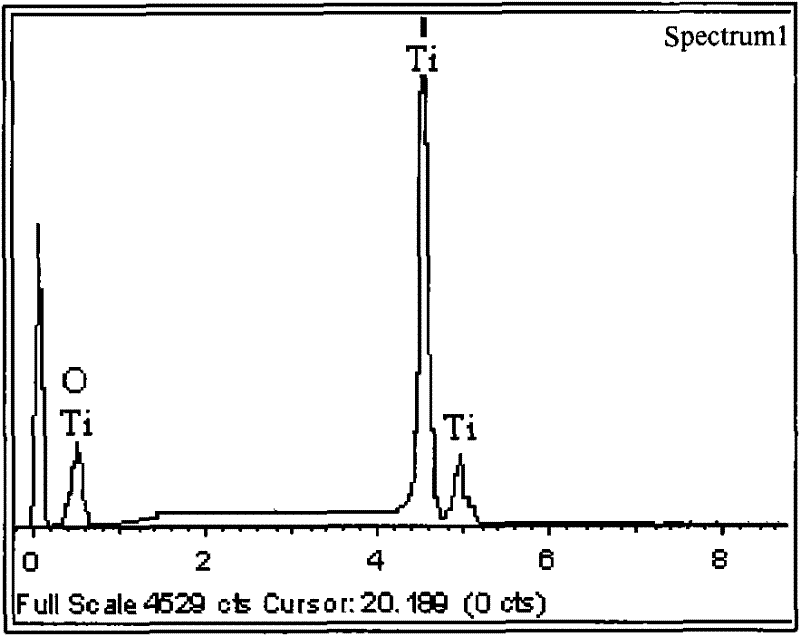

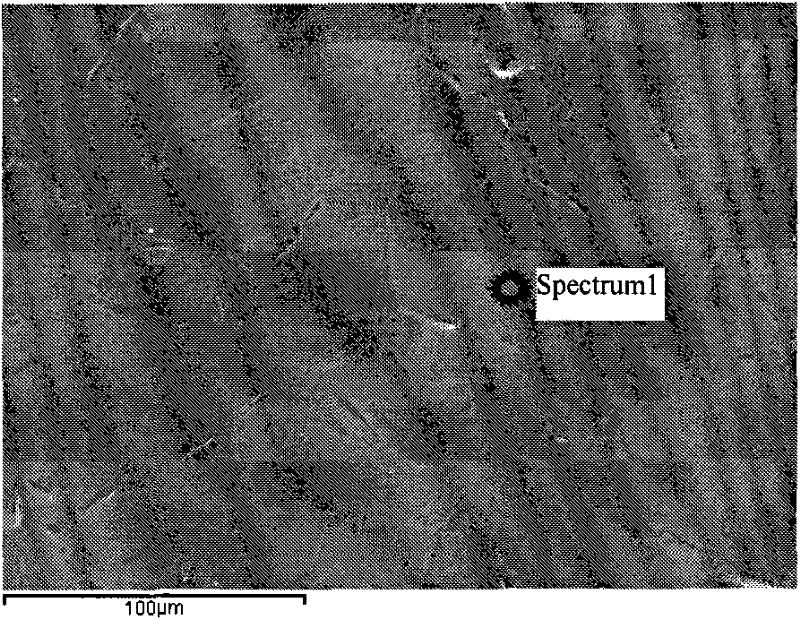

Image

Examples

Embodiment 1-3

[0032] In the embodiment of the present invention 1-3, the titanium / titanium alloy strip surface oxide skin is removed by following steps:

[0033] (1) Electrolysis of acidic aqueous solution: the titanium / titanium alloy strip is placed in the electrolyte, and the titanium / titanium alloy strip is placed in the middle of a pair of electrode plates with the same polarity at a distance of 6 to 12 cm. The polarity of the titanium alloy strip is opposite to that of the electrode plate, and then direct current is passed through the electrolyte, and the current density is 15-25A / dm 3 , the electrolyte is H with a concentration of 150-350 g / L 2 SO 4 solution, the electrolyte temperature range is 60-85°C, and the electrolysis time is 60-200s. During the electrolysis process, the polarity of the titanium / titanium alloy strip alternately changes to anode and cathode, and the polarity of the titanium / titanium alloy strip The time ratio t between the anode and the cathode is 2-4.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com