Method for removing squame from marine low-temperature metalloproteinase (MP) hydrolysis hairwork

A low-temperature protease and hair product technology, applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., can solve the problem that the tensile strength, moisture retention and anti-ultraviolet oxidation performance of color hair products are reduced, the degree of hydrolysis is difficult to control, and the color is affected. Issues such as quality and grade of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare 0.2% by mass of calcium chloride, 500L of borax buffer solution with pH 9, add 15g of marine low-temperature protease MP (product sold in the Yellow Sea), 500ml of penetrant fatty alcohol polyoxyethylene ether, add the hair products washed and dried in water after mixing 5 kg, after 8 hours of treatment at 25°C, remove the hair product, wash it and dry it in the air.

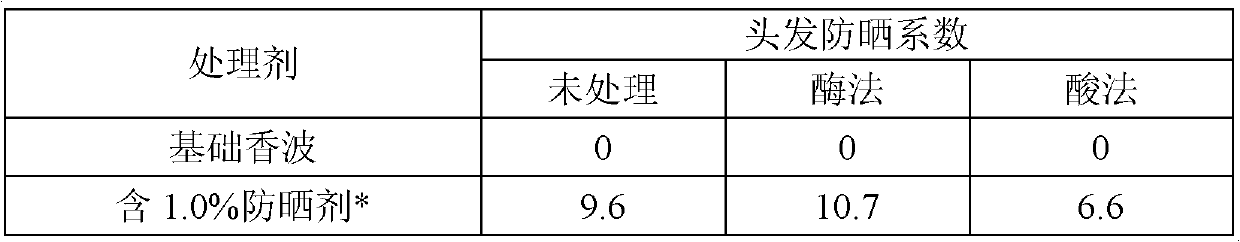

[0017] In the above-mentioned dried enzymatically treated hair products, 50 hairs were randomly selected for hair strength measurement, the average tensile strength reached 140.8g, and the average hair sun protection factor reached more than 10.7.

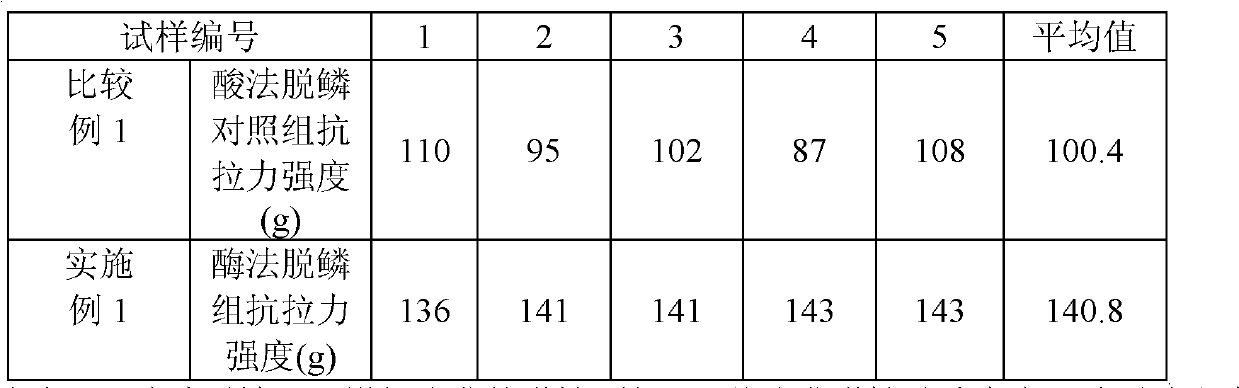

[0018] Comparison of tensile strength after enzymatic and acid descaling: listed in Table 1

[0019]

[0020] Experiments have proved that enzymatic descaling can increase the elasticity of hair, which can be intuitively reflected from the hair elasticity test (see the table above), and it can be seen from Table 1 that the tensile strength can be in...

Embodiment 2

[0028] Prepare 0.3% by mass calcium chloride, 500L of borax buffer solution with pH 9, add 20g of marine low-temperature protease MP, 500ml of penetrant fatty alcohol polyoxyethylene ether, mix well, add 5kg of washed and dried hair products, and treat at 25°C After 8 hours, remove the hair product and wash it with water to dry.

[0029] In the above-mentioned dried enzymatically treated hair products, 50 hairs were randomly selected for hair strength measurement, the average tensile strength reached 140.3g, and the average hair sun protection factor reached more than 10.2.

Embodiment 3

[0031] Prepare 0.25% by mass of calcium chloride, 500L of borax buffer solution with pH 9.5, add 17g of marine cryogenic protease MP, 500ml of penetrant fatty alcohol polyoxyethylene ether, mix well, add 5kg of hair products washed and dried in water, and treat at 25°C After 9 hours, remove the hair product and wash it with water to dry.

[0032] In the above-mentioned dried enzymatically treated hair products, 50 hairs were randomly selected for hair strength measurement, the average tensile strength reached 141.5 g, and the average hair sun protection factor reached more than 11.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com