Drilling Hydraulic Enlarging Net Cage Cast-in-situ Anchor Construction Head and Construction Method

A construction method and hydraulic technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of grid block falling off, low pullout resistance of anchors, corrosion of anchors, etc., so as to improve anti-skid safety. coefficient, increase the anchorage area and reinforcement area, and enhance the effect of sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

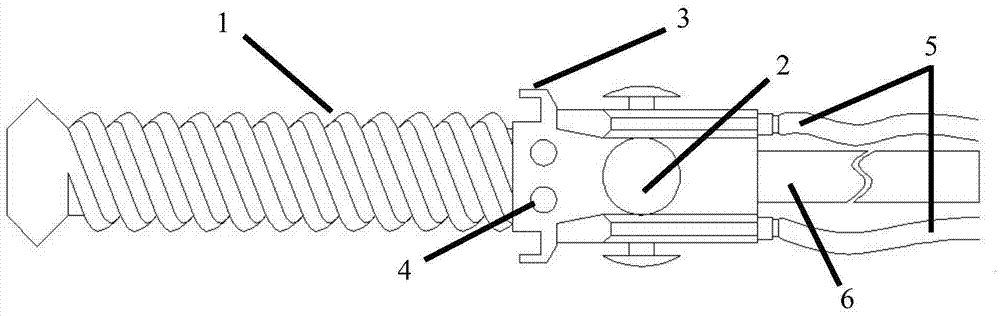

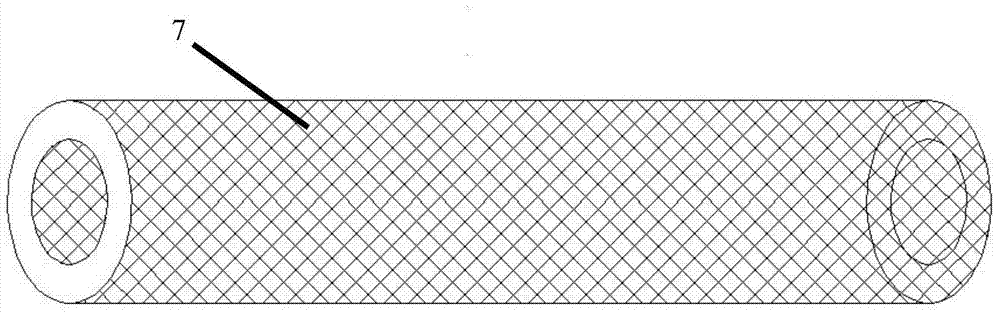

[0024] The overall structure of the construction head of drilling hydraulic enlarged mesh cage cast-in-place anchor includes drilling screw head 1), hydraulic jacking head 2), wire mesh cage hook 3), spray hole 4), hydraulic oil inlet pipe and oil outlet pipe 5 ), drilling into the ejector rod 6), barbed wire cage 7):

[0025] 1) The drilling screw head adopts a straight helical single-rotation single-head structure, which is located at the front end of the construction machine head and connected with the construction machine head;

[0026] 2) The hydraulic jacking head is an umbrella-shaped structure with a wide top and a narrow bottom. The 4 hydraulic jacking heads are evenly distributed on the construction head up, down, left, and right. The rear of the slurry hole is located in the front of the hydraulic inlet and outlet pipes and the drilling jack, and the hydraulic jack can be freely expanded and contracted under the action of hydraulic pressure;

[0027] 3) The wire me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com