Repair method for inspection well and similar structures

A repair method and inspection well technology, applied in underwater structures, buildings, infrastructure engineering, etc., can solve the problems of rapid repair construction of urban inspection wells, corrosion resistance, high construction cost, etc., and achieve good medium resistance Permeability, good acid and alkali corrosion resistance, and short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

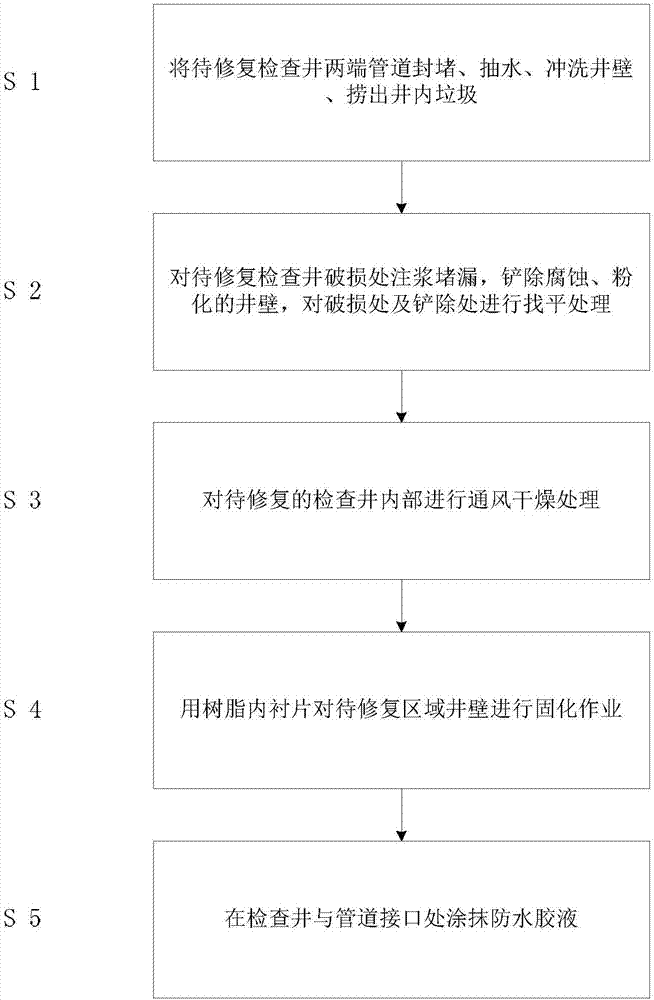

Method used

Image

Examples

Embodiment

[0087] 1. Preparatory work: Park the construction equipment according to the construction requirements, prepare the construction materials, etc., and set up the shading shed;

[0088] 2. Inspection well dredging: block the main pipeline, wash and clean the scaling on the well wall with high-pressure water, remove the sediment at the bottom of the well, pump out the sewage in the well that affects the construction, and dry the well wall to the degree required by the construction with a blower ;

[0089] 3. Pretreatment of damaged parts: grouting plugging for leaks in inspection wells, eradicating corroded and pulverized well walls, and leveling the damaged and eradicated parts of well walls with light-curing sealing paint and quartz sand;

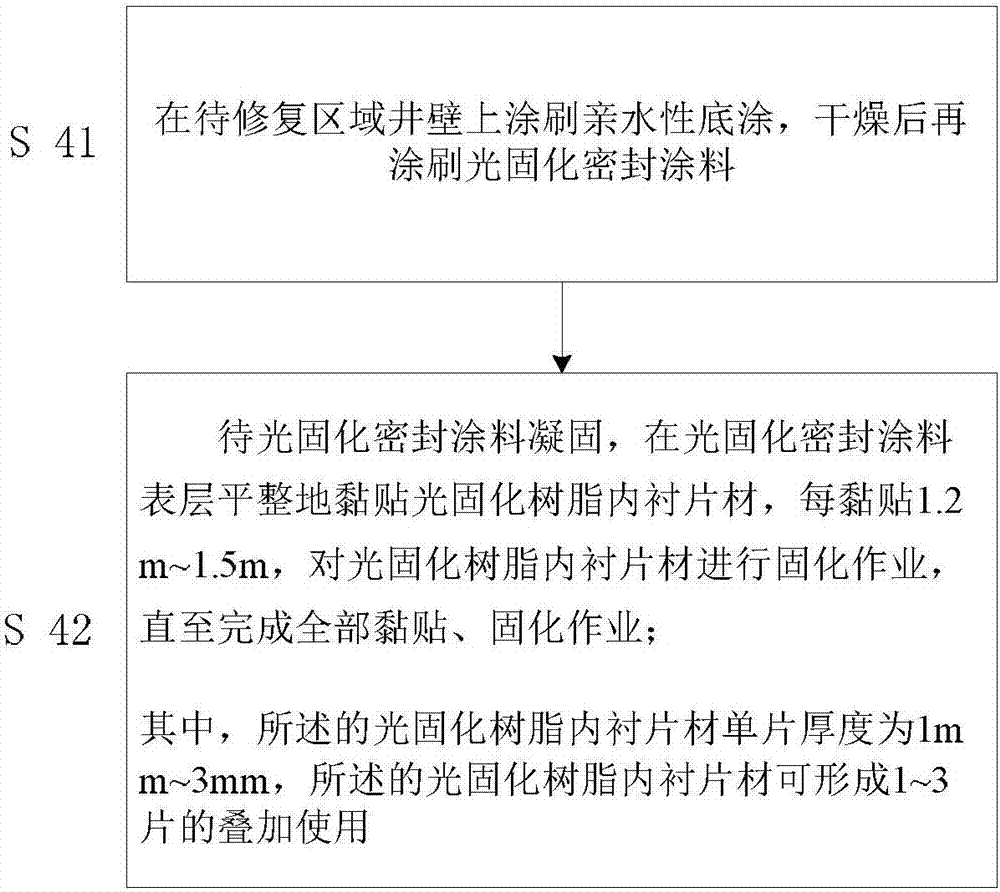

[0090] 4. Substrate treatment: Ventilate and dry the inside of the pretreated inspection well to ensure that there are no water droplets on the well wall and the relative humidity is below 80%. Apply a hydrophilic primer on the well wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com