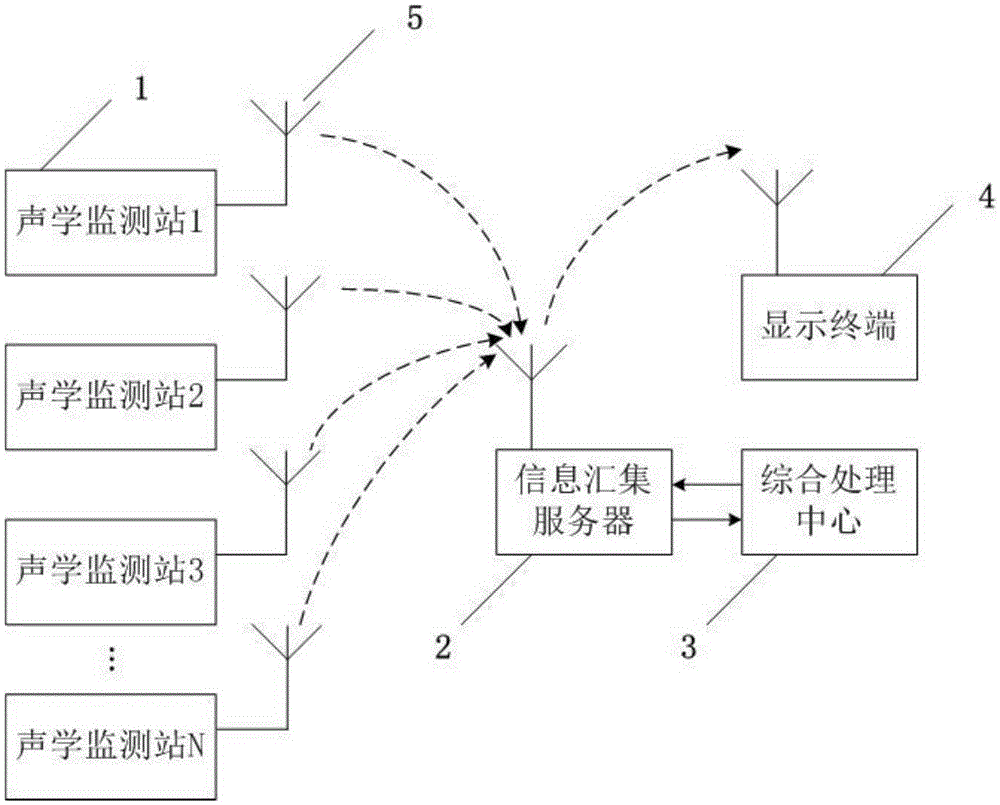

Acoustic monitoring station, wheel detection method and train bearing fault passive acoustic diagnosis system

A fault diagnosis system and monitoring station technology, applied in mechanical bearing testing, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problems of multiple vibration sources, failure to diagnose bearing faults, long cycle, etc., to reduce potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

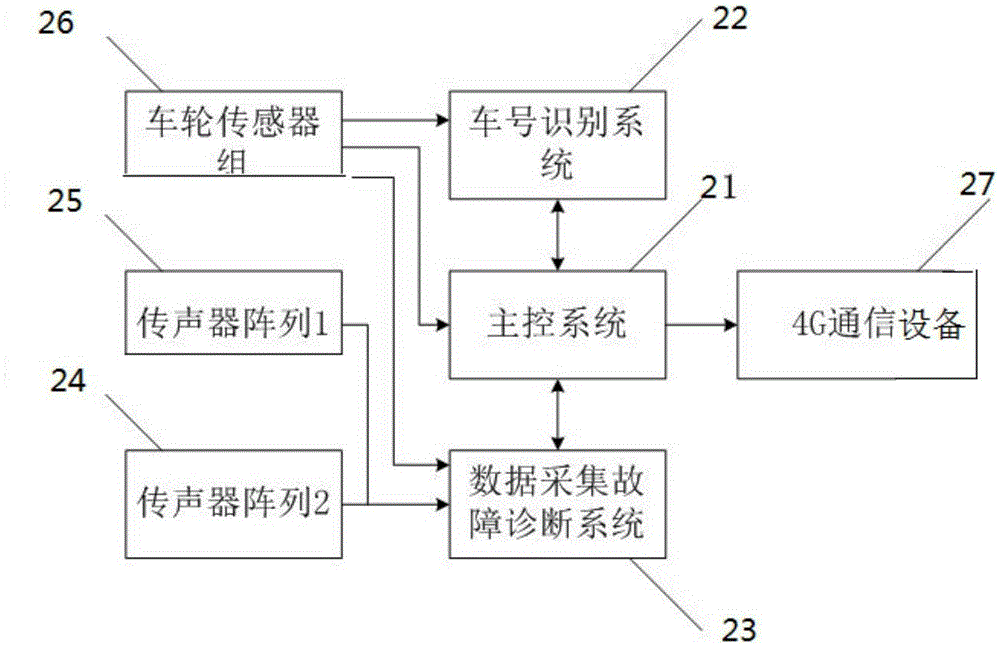

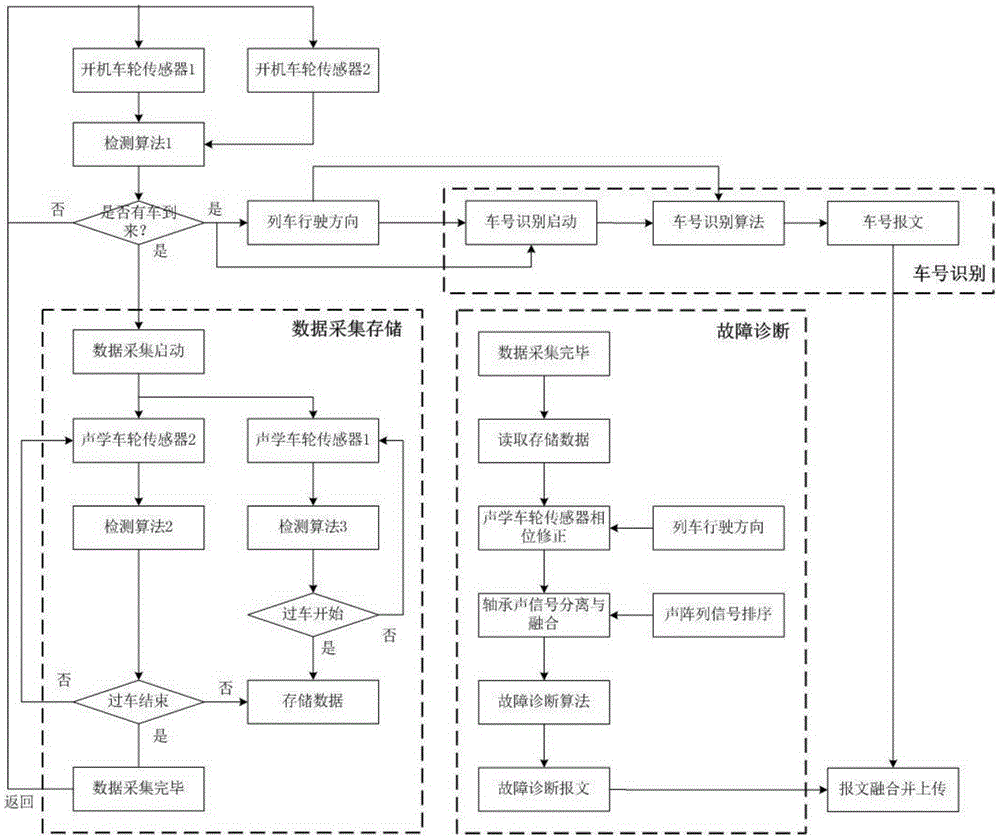

[0038] Such as figure 2 As shown, according to an embodiment of the present invention, the acoustic monitoring station 1 includes a main control system 21, a vehicle number identification system 22, a data acquisition fault diagnosis system 23, two sets of line array microphone arrays 24, 25, a wheel sensor group 26. 4G communication equipment 27; the main control system 21 unifies the deployment system workflow; the wheel sensor group 26 includes six wheel sensors, two of which are used as acoustic wheel sensors to assist in the collection of bearing acoustic signals, and are respectively separated from the two ends of the microphone line array Microphone 1.5 meters, two boot wheel sensors for two-way pick-up, 60 meters away from two acoustic wheel sensors respectively, two-way pick-up means that the train can drive from left to right or from right on the same train track Open on the left, the system designed by the present invention can start and work normally when the trai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com