Examination method of forming die of plastic-aluminum composite membrane of polymer lithium-ion battery

A technology of aluminum-plastic composite film and lithium-ion battery, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as misjudgment, achieve convenient judgment, avoid failure, and have practical value

Active Publication Date: 2016-01-20

HANGZHOU FUTURE POWER TECH +1

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that after the aluminum-plastic composite film is stretched, because the corner is relatively thin, there will be misjudgment when the fillet radius (R value) at the corner of the mold is unreasonably set.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

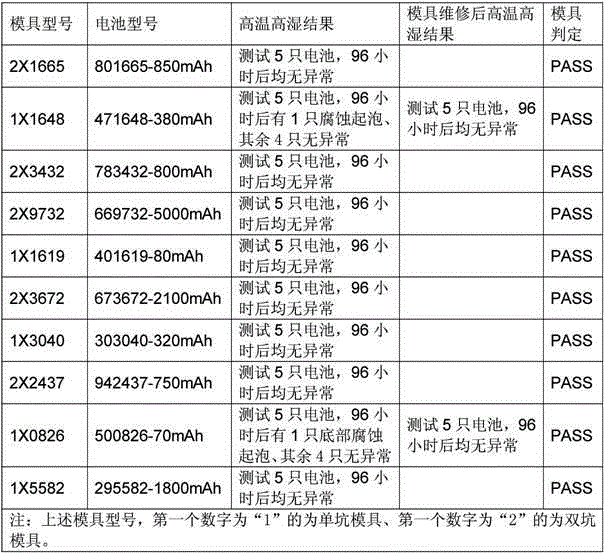

The invention, which belongs to the field of the polymer lithium-ion battery manufacture technology, discloses an examination method of a forming die of a plastic-aluminum composite membrane of a polymer lithium-ion battery. In the prior art, the existing examination die has the defect of wrong judgment. According to the invention, actual processing of a batter is carried out based on lithium battery production simulation and then examination is carried out. The method comprises the following steps: (1), carrying out battery housing moulding; (2), manufacturing a finished battery; (3), obtaining a serial number of each position of the finished battery; (4), carrying out high-temperature high-humdity examination; and (5), carrying out determination. With the method, the actual process of the product application is met; the operation becomes simple, convenient, and effective; a fault point of a die can be determined conveniently in real time; stability of batch production of the batteries can be fully guaranteed; and thus the examination method had the great practical value during the production process.

Description

technical field [0001] The invention belongs to the manufacturing technology of polymer lithium ion batteries, in particular to an inspection method for forming molds of aluminum-plastic composite films of polymer lithium ion batteries. Background technique [0002] According to the different electrolyte materials used in lithium-ion batteries, lithium-ion batteries are divided into liquid lithium-ion batteries (LiquifiedLithium-IonBattery, referred to as LIB) and polymer lithium-ion batteries (PolymerLithium-IonBattery, referred to as PLB) or plastic lithium-ion batteries (PlasticLithium-IonBatteries , referred to as PLB). [0003] The positive and negative electrode materials used in polymer lithium-ion batteries are the same as liquid lithium ions. The positive electrode materials are divided into lithium cobaltate, lithium manganese oxide, ternary materials and lithium iron phosphate materials. The negative electrode is graphite, and the working principle of the battery ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R31/36

Inventor 陈先学郑长明陈淑青曹敏贾新涛

Owner HANGZHOU FUTURE POWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com