Turning machine and manufacturing method of liquid crystal panel

A manufacturing method and flipping machine technology, applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of liquid crystal box 10 invalidation, puncture plastic frame, liquid crystal impact, etc., and achieve the effects of easy processing, safe and efficient use, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

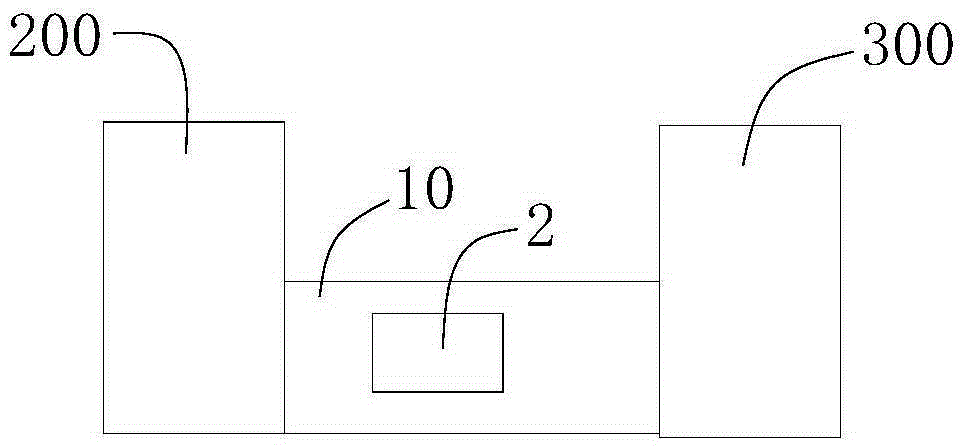

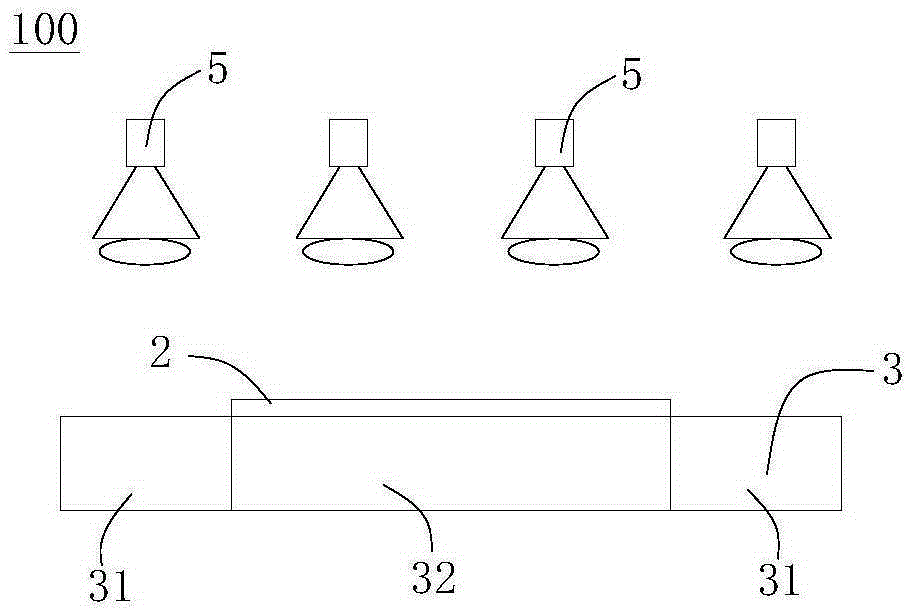

[0022] figure 1 The liquid crystal cell turning machine 10 according to the present invention is shown. The liquid crystal cell turning machine 10 is usually applied between the box forming equipment and the curing equipment. The box forming equipment can bond the first substrate with an uncured plastic frame to the first substrate injected with liquid crystal. On the second substrate, a liquid crystal cell is formed, and then the liquid crystal cell is turned over by a liquid crystal cell turning machine 10 and transported to a curing device.

[0023] Such as figure 1 As shown, the liquid crystal cell inverting machine 10 includes an inverting mechanism 3 for inverting the liquid crystal cell 2 . In one embodiment, the turning mechanism 3 is mainly composed of a turning device capable of turning over the liquid crystal cell 2 and transporting it to the curing device. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com